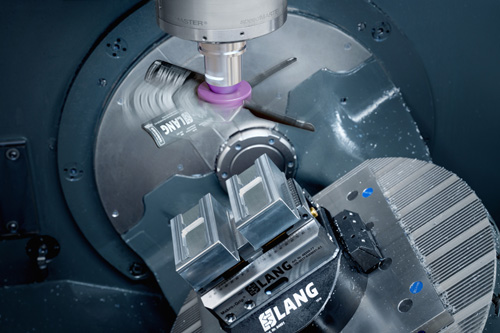

Makro•Grip® - the benchmark in 5-axis machining

Raw Part Clamping

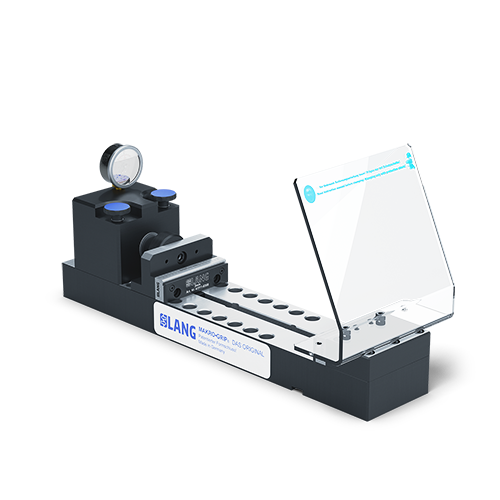

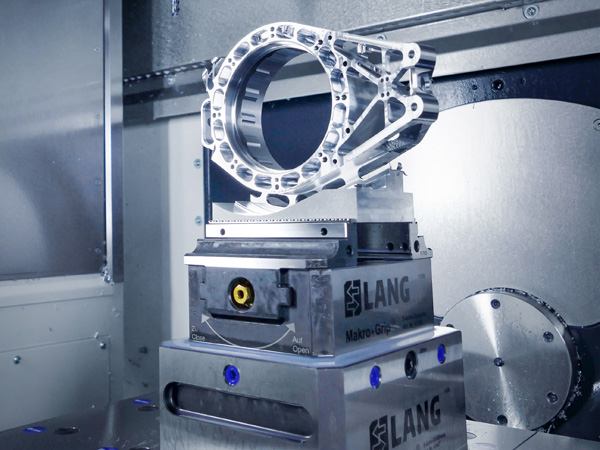

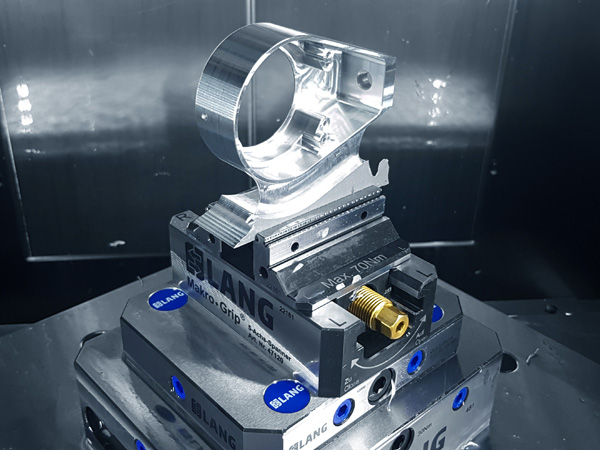

The Makro•Grip® 5-Axis Vise is the perfect workholding device for 5-sided machining of blanks. Due to its very compact design and low interference contours, it offers best accessibility to the workpiece. The form-fit effect ensures highest holding forces even with low clamping pressure and guarantees maximum process reliability.

Learn moreStamping Technology

The Stamping Technology is considered today’s benchmark in workholding due to its profitable influences on the clamping process in the 5-sided machining of blanks. During the pre-stamping process, which takes only 5 seconds, the raw material is provided with a defined contour and then held by a form-fit effect in the serrated clamping jaws of the 5-Axis Vise.

Learn more

Makro•Grip® Raw Part Clamping

Compact and unmatched holding power for the 5-sided machining of blanks and unfinished parts

External pre-stamping makes it possible to hold a workpiece in the Makro•Grip® 5-Axis Vise with low clamping pressure in a process-safe manner. Deformation and distortion of the material during clamping and release are thus excluded and wear on the clamping device is reduced to a minimum.

Its compact design and high holding forces due to the form-fit clamping make the 5-Axis Vise the ideal workholding device in the 5-sided machining of raw parts.

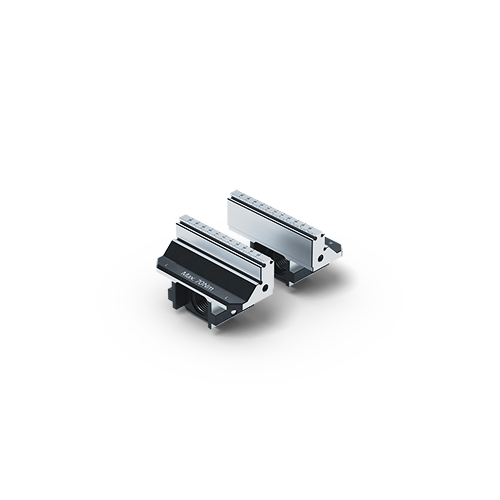

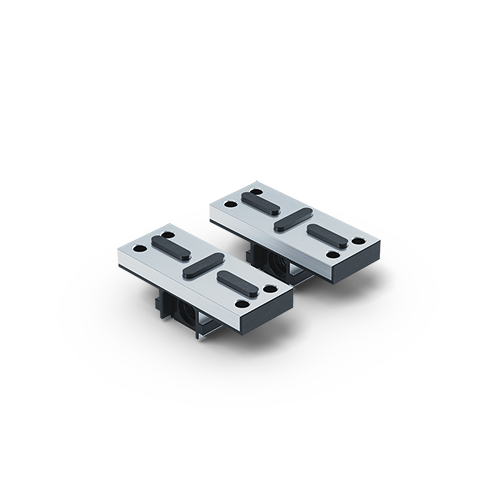

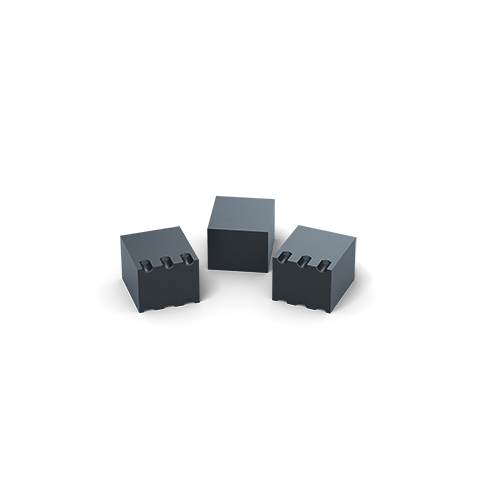

Serration

- Reversible jaw with Makro•Grip® serration on both sides or with flat clamping step, for increasing the clamping range and eliminating interfering contours

- The clamping depth of 3 mm guarantees ideal accessibility and material savings

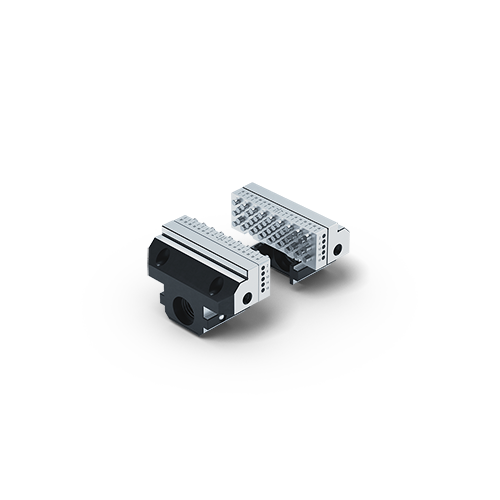

Clamping jaws

- Clamping jaws and guide milled from solid material for maximum stability

- Increased parallelism due to spring loaded jaw guide

Additional clamping options for the second operation

- Plain surfaces provide additional clamping options for the second operation

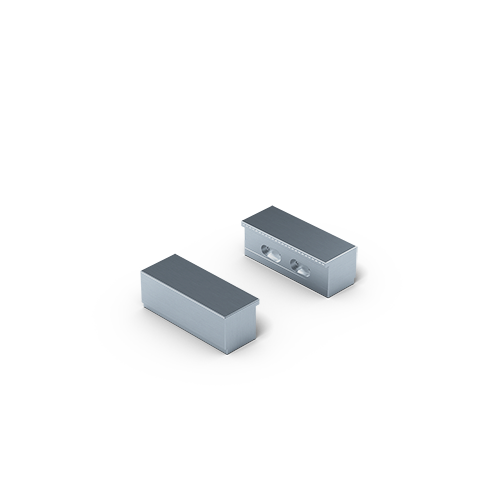

Base

- Sturdy and robust base made of case-hardened steel for maximum durability, fully compatible with Avanti, Profilo and Vario•Tec type clamping jaws

- Lateral grooves as chip and coolant drain

- Additional automation interface for selected variants

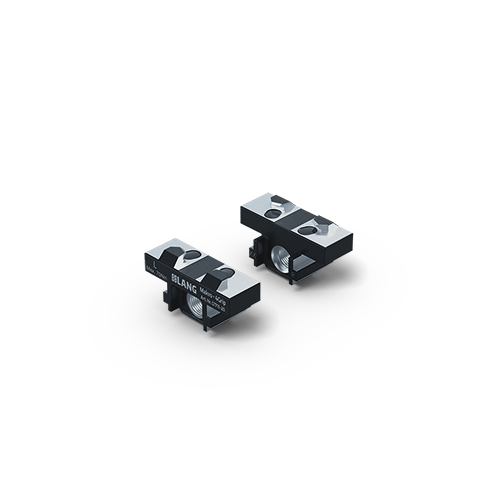

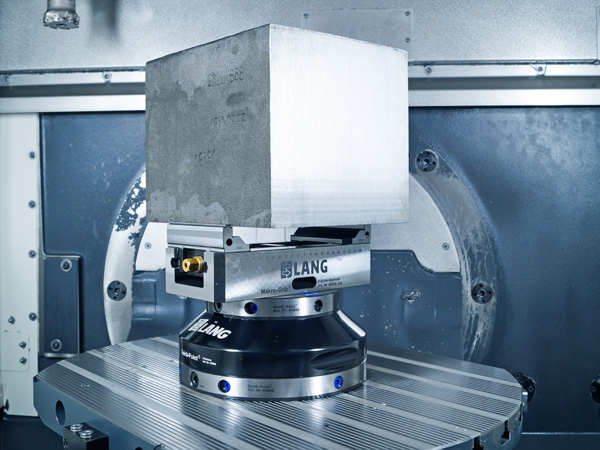

Zero-point interface

- Equipped with clamping studs for precise clamping in the Quick•Point® Zero-Point Clamping System

Encapsulated center piece

- Encapsulated center piece, centering accuracy ± 0.02 mm

- Center piece can be replaced by center jaw to realize dual clamping

Makro•Grip® Technology

Benefits of the Makro•Grip® 5-Axis Vise

Raw part machining with the Makro•Grip® 5-Axis Vise

Small to big – All Makro•Grip® 5-Axis Vises

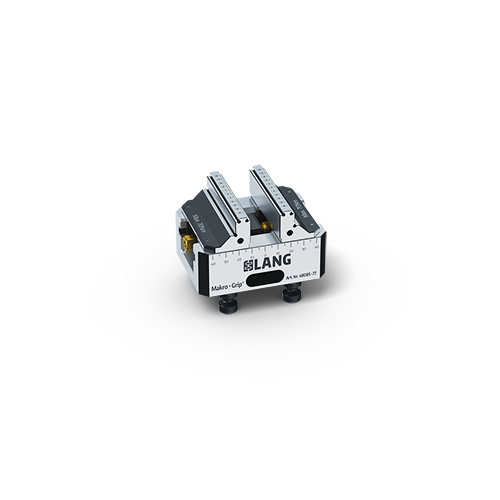

Makro•Grip® 5-Axis Vise 77

Jaw width 46 mm, clamping range up to 85 mm

Makro•Grip® 5-Axis Vise 77

Jaw width 46 mm, clamping range up to 120 mm

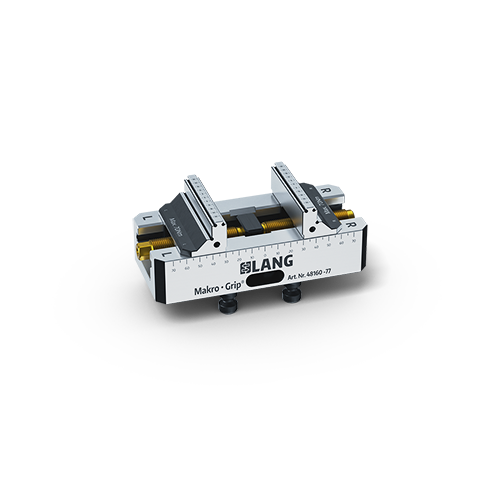

Makro•Grip® 5-Axis Vise 77

Jaw width 77 mm, clamping range up to 85 mm

Makro•Grip® 5-Axis Vise 77

Jaw width 77 mm, clamping range up to 120 mm

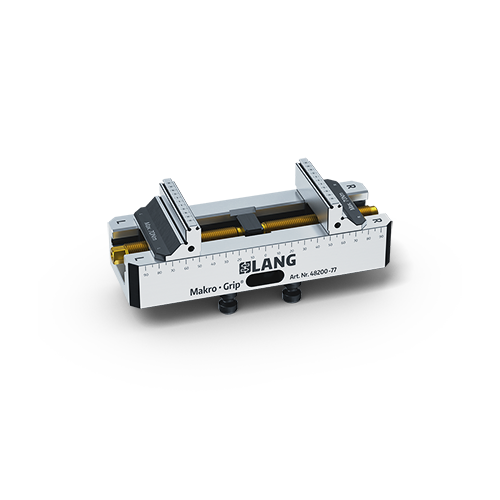

Makro•Grip® 5-Axis Vise 77

Jaw width 77 mm, clamping range up to 160 mm

Makro•Grip® 5-Axis Vise 77

Jaw width 77 mm, clamping range up to 200 mm

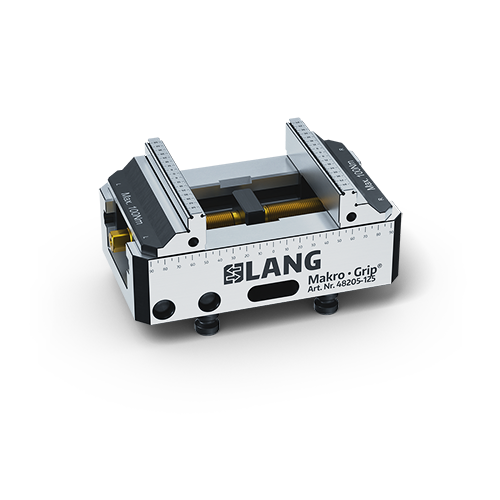

Makro•Grip® 5-Axis Vise 125

Jaw width 125 mm, clamping range up to 155 mm

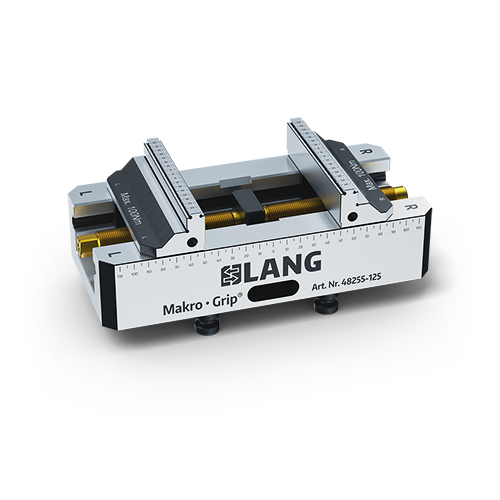

Makro•Grip® 5-Axis Vise 125

Jaw width 125 mm, clamping range up to 205 mm

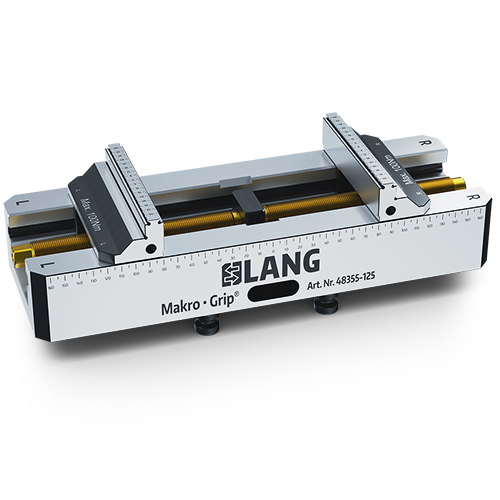

Makro•Grip® 5-Axis Vise 125

Jaw width 125 mm, clamping range up to 255 mm

Makro•Grip® 5-Axis Vise 125

Jaw width 125 mm, clamping range up to 305 mm

Makro•Grip® 5-Axis Vise 125

Jaw width 125 mm, clamping range up to 355 mm

Makro•Grip® 5-Axis Vise 125

Jaw width 77 mm, clamping range up to 155 mm

Makro•Grip® 5-Axis Vise 125

Jaw width 77 mm, clamping range up to 205 mm

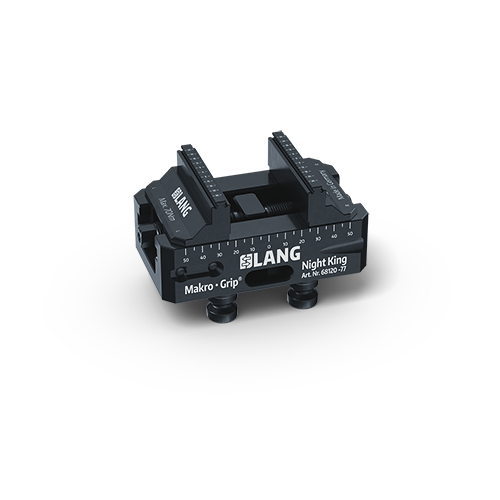

Makro•Grip® Night King

Jaw width 77 mm, clamping range 0 – 120 mm

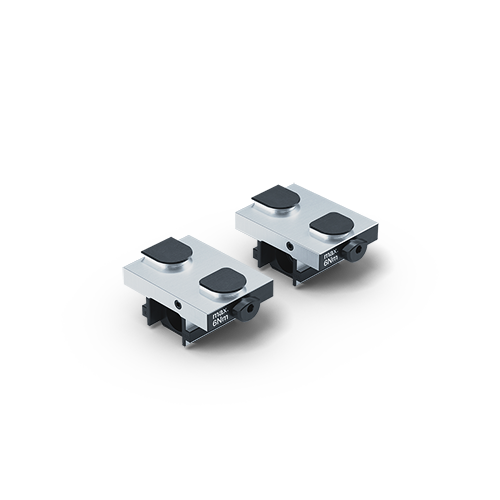

Individual components

One base, many clamping jaw option

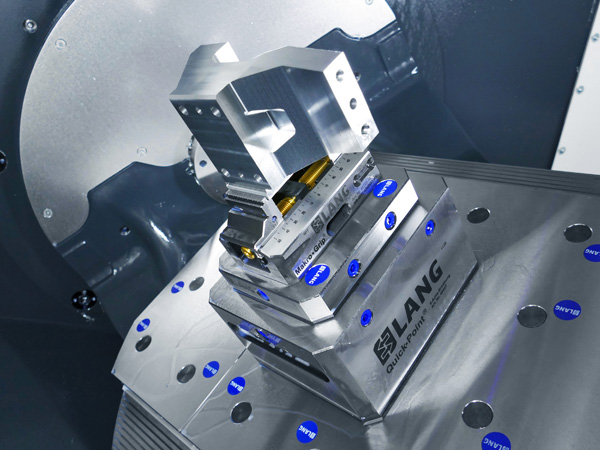

A fitting solution for any challenging clamping task - with only one vise base! All LANG vises use the same base in different lengths and widths. This guarantees that all jaw types are interchangeable and compatible to each other.

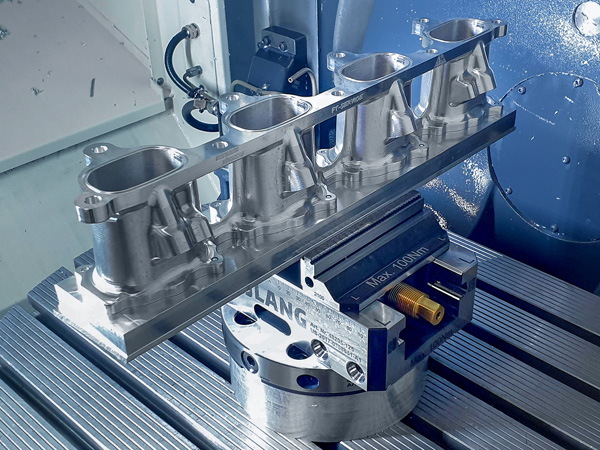

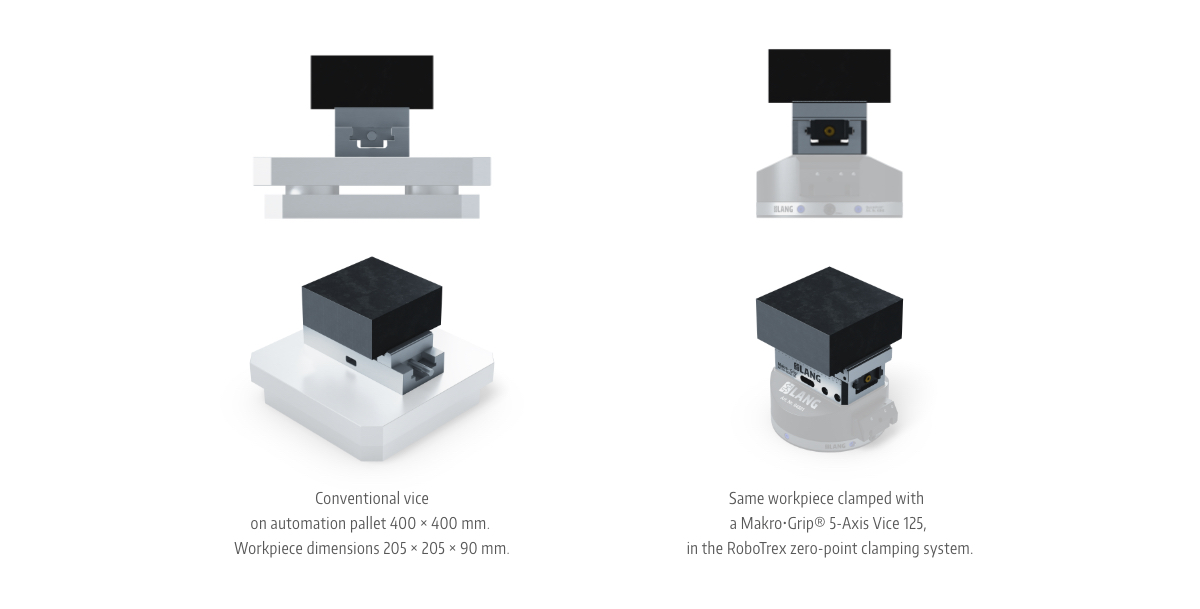

Optimized use of space in automated manufacturing

Pre-stamping and the Makro•Grip® technology allow the 5-Axis Vise to clamp workpieces which substantially exceed its volume. The compact design is in particular beneficial in automated manufacturing, as a huge amount of vises can be stored on a small footprint resulting in a more efficient use of space on the automation trolley and inside the machine. Another huge advantage is that the Makro•Grip® is directly handled by the robot without the requirement of a bulky and expensive pallet, meaning that less weight has to be handled by the robot. Since there are no additional interfaces to the zero-point clamping system and the Makro•Grip® jaws are milled from solid, the 5-Axis Vise offers enormous stability advantages and at the same time ensures an easy and convenient handling thanks to its low weight.

Convinced by the benefits of the Makro•Grip®?

Then simply use the contact form to ask for your individual quote or visit our online shop.

Product overview

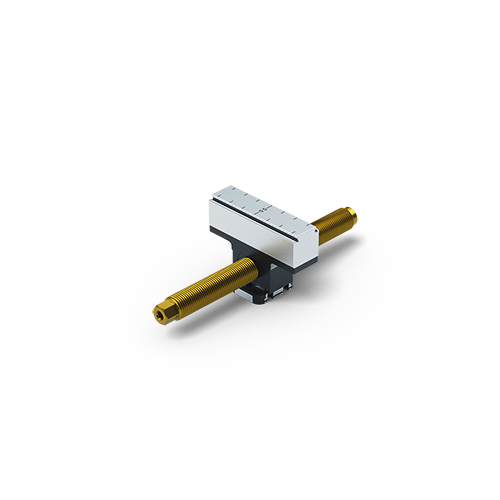

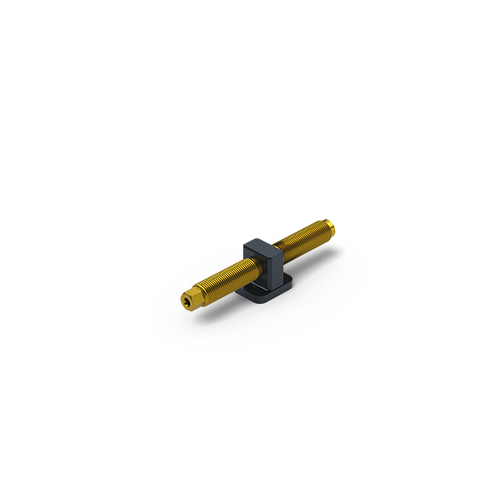

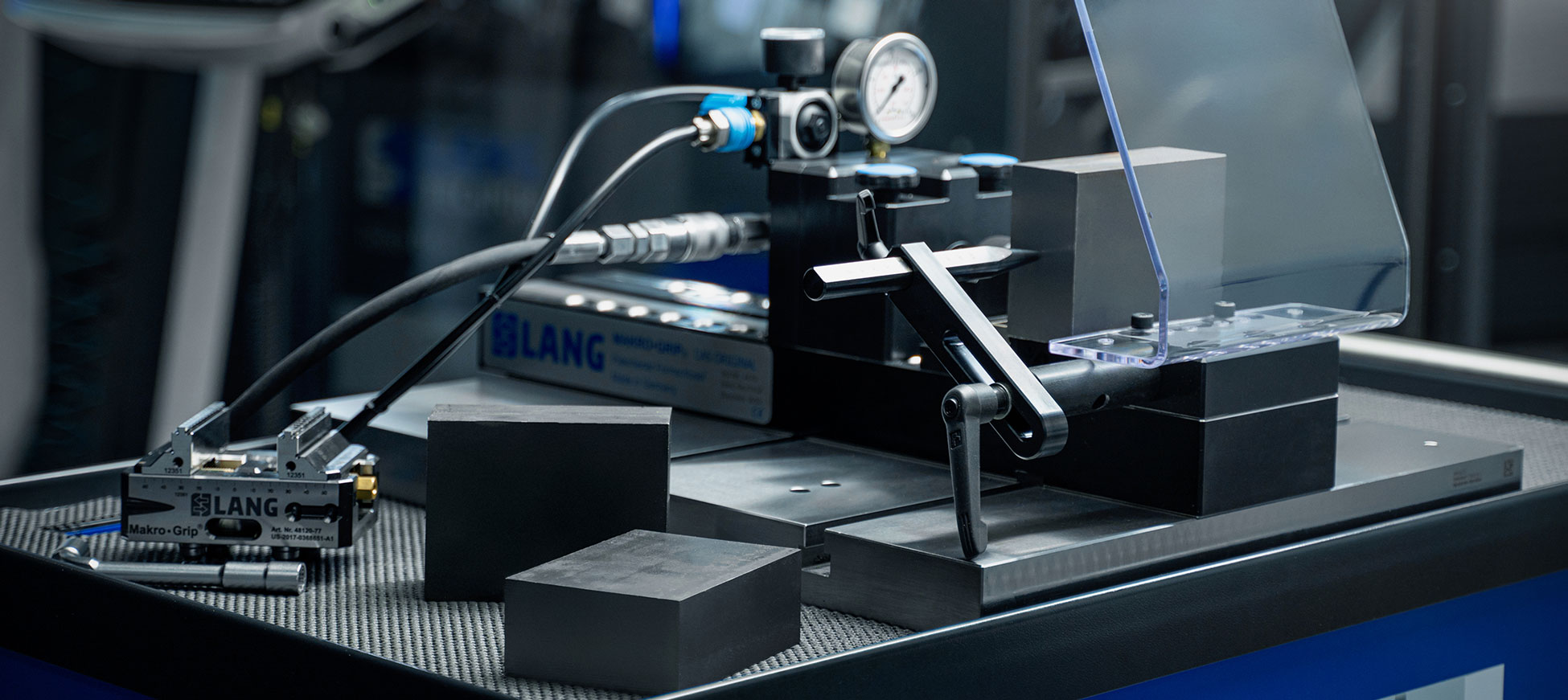

Makro•Grip® Stamping Technology

„The Original“ –

the Stamping Technology by LANG Technik

Stamping Technology

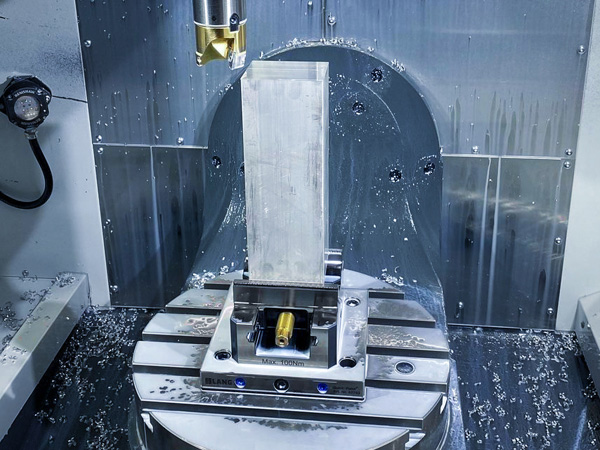

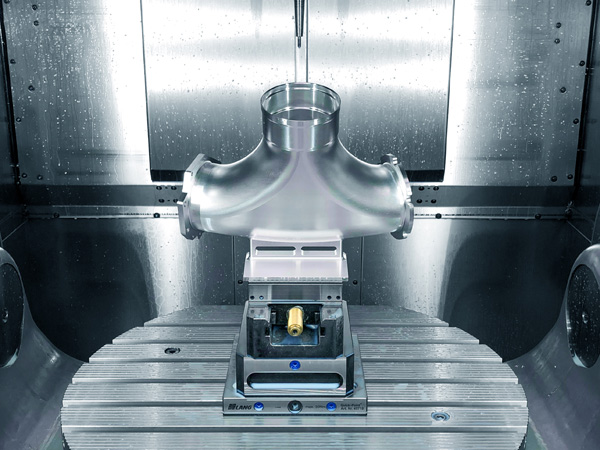

The Stamping Technology was invented by LANG nearly 20 years ago and can be regarded as the heart of the Makro•Grip® workholding. It guarantees highest holding forces and ideal accessibility in 5-axis machining of blanks. The pre-stamping of workpiece blanks favours a variety of factors that have a positive effect on process reliability and cost-efficient production, which is why the Makro•Grip® technology is considered the benchmark in today's workholding. During the pre-stamping process workpieces are prepared with a defined contour at an external stamping unit under high pressure, which generates a form-fit between serrated jaws of the Makro•Grip® 5-Axis Vise and the stamping contour when clamping the workpiece. As pre-stamping is conducted externally, no additional machine capacities have to be spent in order to prepare the workpiece. The process only takes about 5 seconds - but these 5 seconds will forever change your manufacturing processes and the way you clamp your workpieces.

Why pre-stamping a workpiece blank?

Conventional vises penetrate the workpiece blank with high forces exposing both, the vise and the workpiece to high strains. The Makro•Grip® technology however uses a different approach. By pre-stamping the workpiece blank with up to 20 tons of pressure and preparing it with a defined contour, the forces are already applied before the actual clamping process. Once it is prepared with the contour (pyramid-shaped truncated indents), the Makro•Grip® 5-Axis Vise can hold the workpiece by form-fit, absolutely gently and securely with low clamping pressure - always with the same clamping jaws, regardless of the material and the hardness. Due to the low clamping pressure, distortion on the workpiece as well as wear on the vise can virtually be ruled out. Even with high-tensile material an always consistent clamping quality is guaranteed, which is crucial to achieving the desired quality of the machined workpiece.

5 seconds that revolutionize your machining processes!

Benefits of the Makro•Grip® Stamping Technology

Individual components

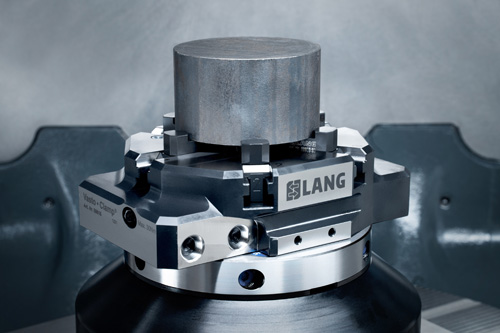

Makro•4Grip – Stamping Technology for round parts

By retrofitting the Makro•Grip® stamping unit and a LANG centering vise the form-fit clamping technology can be applied for round parts easily and cost efficiently. Makro•4Grip clamping jaws are compatible fit every vise size and cover clamping ranges of Ø 36 – 300 mm.

View product category

Pre-Stamping in new dimensions!

Matching stamping units are also available for clamping applications of flat and large components with Makro•Grip® Ultra.

Learn moreSuccess Stories

Start your own success story with Makro•Grip®. This is what our customers say:

Through initial recommendations from the formula 1 industry, we equipped our first 5 axis machine with LANG's Makro•Grip® and their associated zero-point system. Needless to say, we've never looked back. The Makro•Grip® vises offers great work access around the material stock. The high clamping force in combination with indentations by the serrated jaws has never failed to hold our parts firmly. The repeatability of the self-centering vises in combination with the zero-point system ensures we can offer consistent quality components to our customers.

Fredrik Larsson, Aximech AB, Arlöv Sweden

I switched over to LANG Technik workholding products one year ago. I was immediately impressed by the quality and precision of LANG products. My favorite feature by far is the Makro•Grip® system. I’ve noticed a tremendous increase in part stability due to the minimal clamping pressure required to accurately retain parts. Eliminating the need for stock preparation or dovetailing in a CNC machine has been a gamechanger as well. Efficiency has increased considerably. I look forward to growing my collection of LANG workholding products!

Eddie Casanueva, Nueva Precision, Milliken USA

We have used LANG Makro•Grip® vises for many years now and they have provided us extra efficiency and safety in workholding. It is good to see LANG Technik constantly developing new product and improving existing ones. It assures us that we have chosen right partner for our workholding solution.

Kristjan Joost, Afterone ÖU, Tartu Estland

We are absolutely convinced by LANG’s stamping technology and the Makro•Grip® vises. To us the pre-stamping process of raw material has several advantages compared to simply clamping with conventional gripping jaws. As an example: Through an adjustment of the stamping pressure, the stamping contour pattern can be realised across the entire jaw width, even when the raw material is not a 100% parallel. This ensures an absolutely safe clamping process with the 5-axis vise, even with strong machining forces and parts with a huge overhang. Furthermore, we do not need an end stop, as the stamping contour determines the position in the vise. This guarantees us optimal accessibility from all sides.

Sebastian Thoma, Thoma-Tec, 84155 Bodenkirchen

Various Makro•Grip® clamping applications

We leave an impression! Also (soon) in your production?

Product overviewLearn more about other solutions by LANG

RoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

More detailsQuick•Point® Zero-Point Clamping System

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

More detailsQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

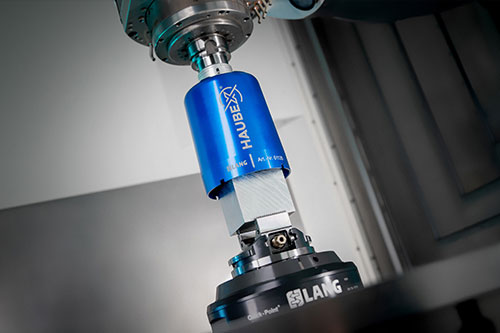

More detailsHAUBEX Automation System

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vise and workpiece blank.

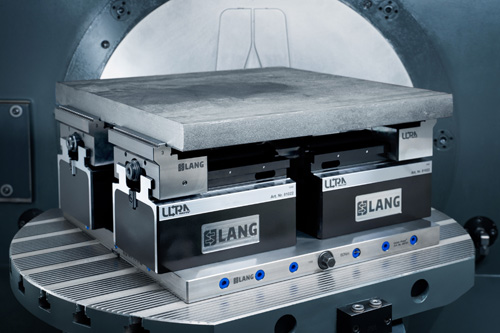

Learn moreMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

More detailsConventional Workholding

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

More detailsClean•Tec Chip Fan

The chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

More details