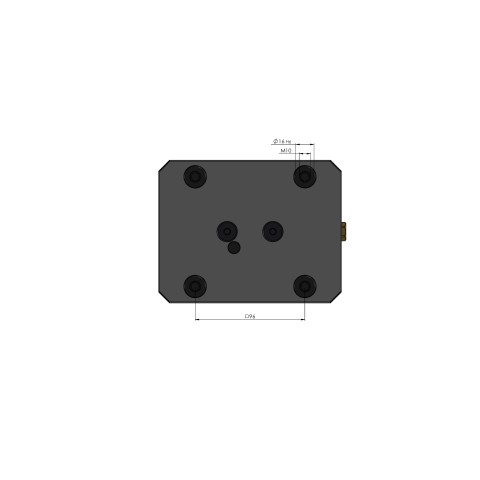

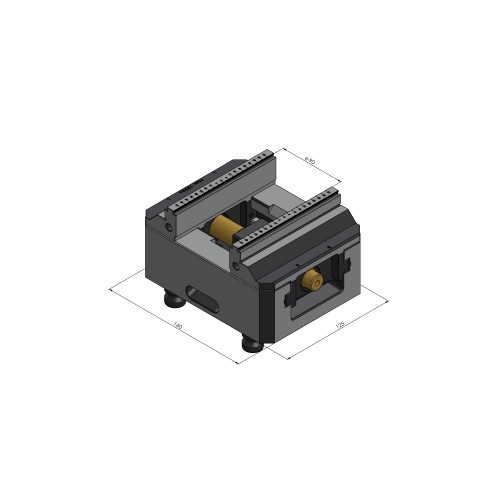

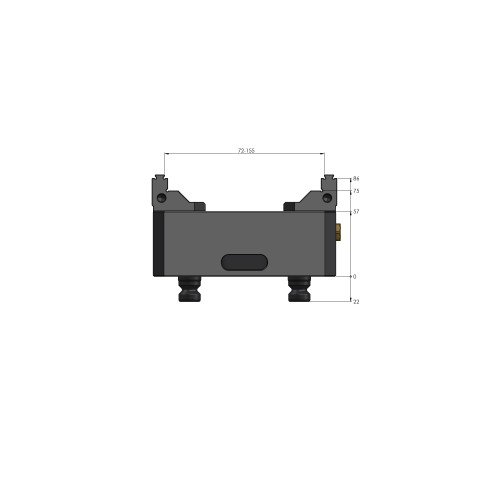

Key data at a glance

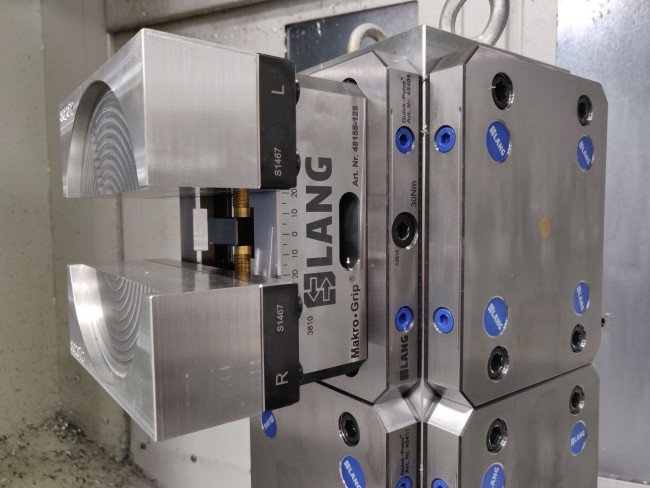

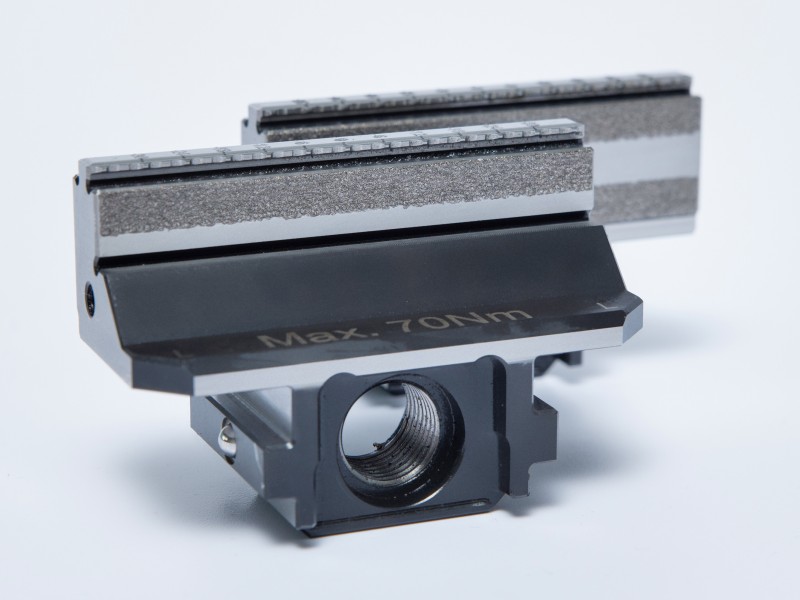

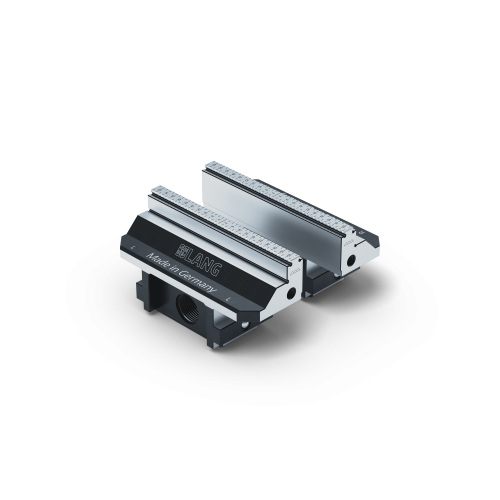

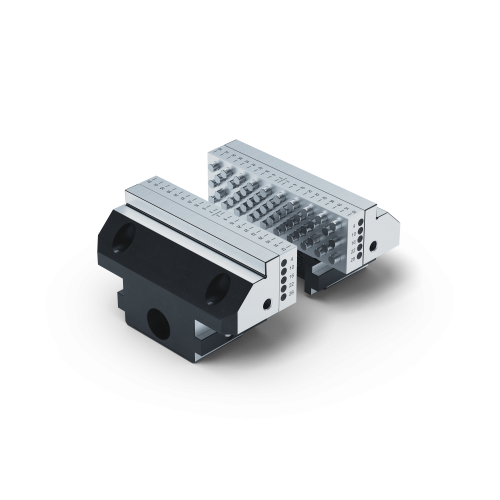

The shortest 5-axis vise with a jaw width of 125 mm has a maximum clamping range of 155 mm with a base body length of just 160 mm. Its compact design, the large clamping range compared to the base body and the good accessibility from all sides, offer excellent conditions for 5-axis machining of blanks. With its jaw serration, the vise holds pre-stamped blanks by form-fit. As a result, only very low pressure is required to clamp components with extreme hold and a high degree of safety. But even without pre-stamping, the 5-axis vise guarantees maximum hold at high cutting forces in raw part machining.

More features:

Single components features:

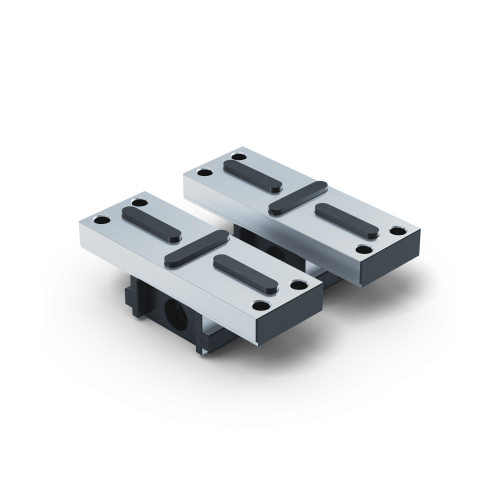

Spare Jaws

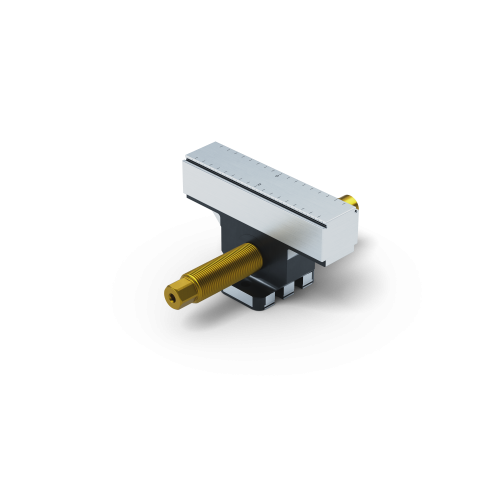

Spindle + Center Piece

Clamping Studs

Makro•Grip® Stamping Technology and Raw Part Clamping

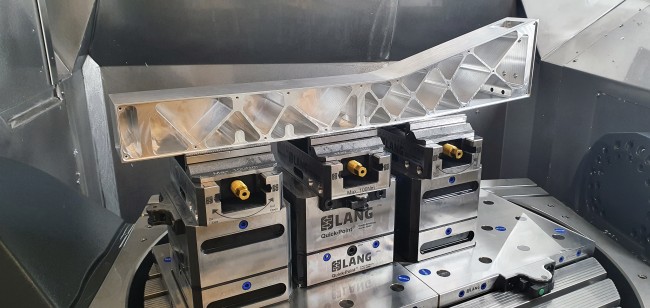

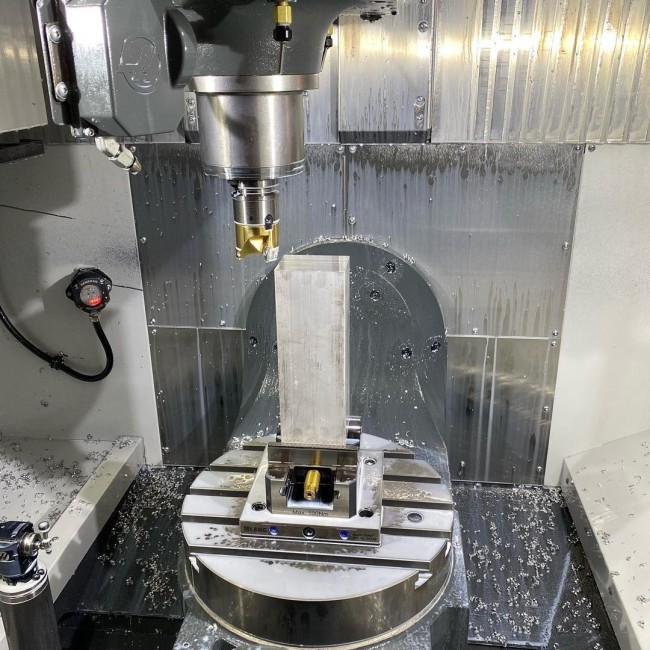

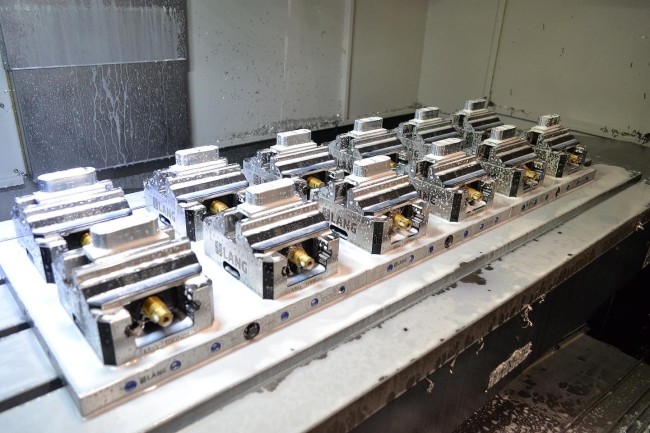

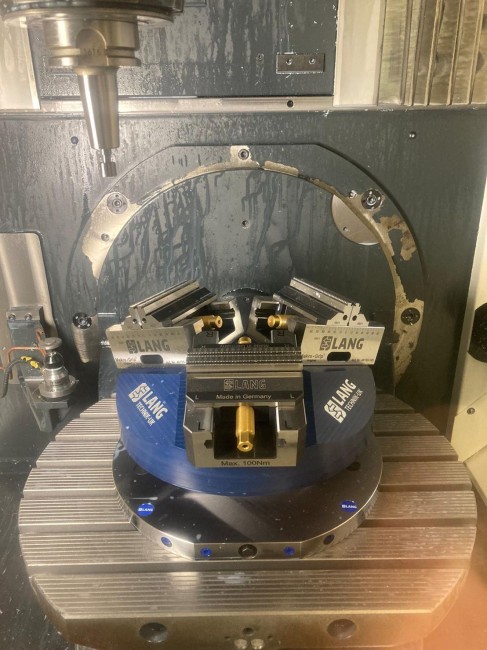

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

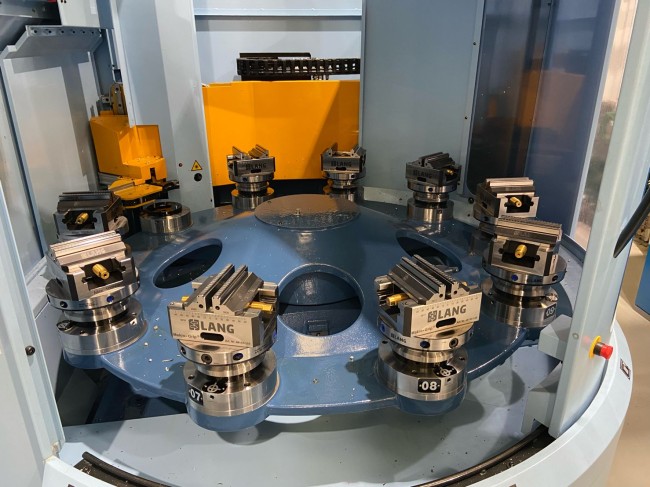

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover nowApplication pictures

Application videos

Services

We will be happy to advise you individually and adapt your products for the best possible application.

Tungsten-Carbide-Coating

A special Tungsten-Carbide Coating can be applied on the plain clamping surfaces of the Mak-ro•Grip® jaws in order to double the friction force when clamping non-stamped parts, without leaving any traces on the workpiece.

Modified Clamping depth

Sometimes raw material has a certain radius, which makes it hard to clamp it on the 3 mm step of the Makro•Grip® jaws. This can be solved by lowering the clamping step so that the workpie-ce is held above the radius. On the one hand, this provides a resting surface for the workpice, on the other hand it ensures safe clamping.