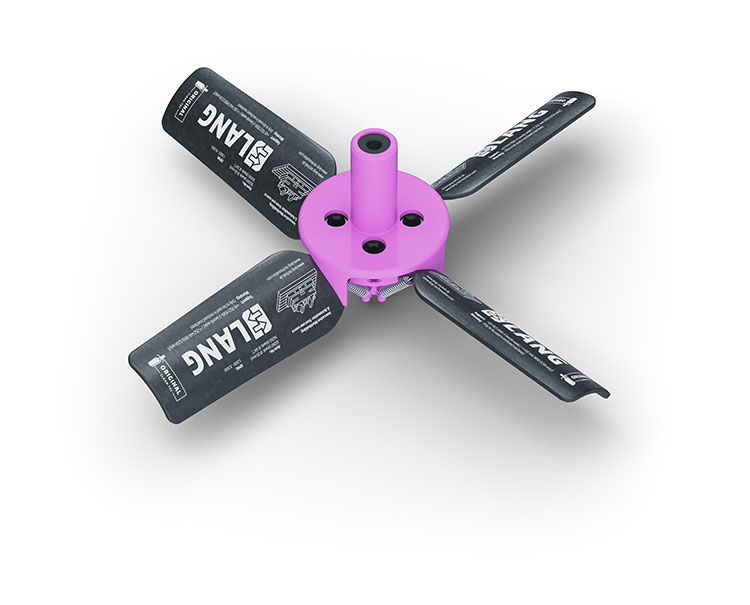

Clean•Tec Chip Fan – “The Original”

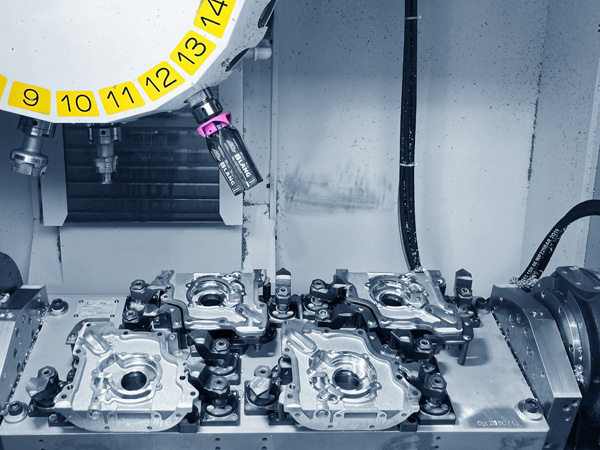

The automatic cleaning of workpieces and fixtures after the machining process

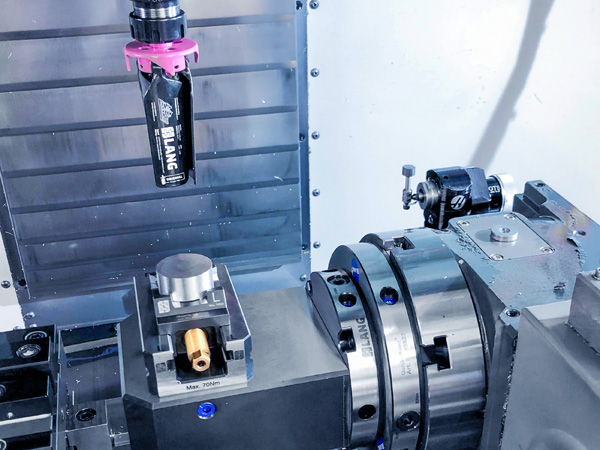

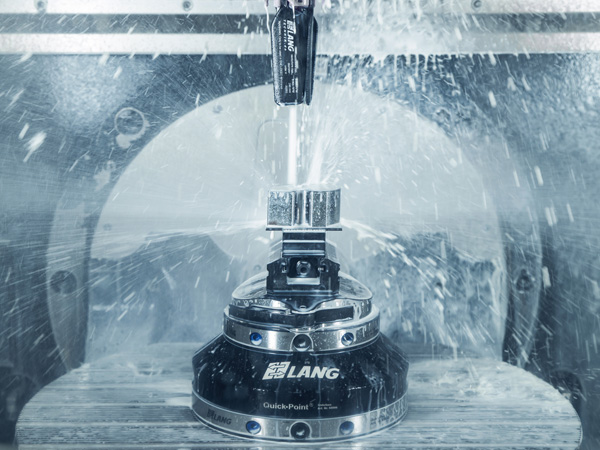

The Clean•Tec, “The Original” Chip Fan cleans the machine interior after machining processes, removing chips and coolant without the operator having to open the machine tool door. As a final step in the machining process, the Chip Fan is called up via the machine program and selected from the tool magazine.

Its blades are opened and closed by controlling the speed of the machine tool spindle. Especially in automated manufacturing the Clean•Tec is a must-have. Prior to the automatic unloading, the Chip Fan cleans all relevant interfaces between workholding fixtures and thus ensures a clean and reliable process.

Base Body

- Robust base body with steel core, can be clamped in any standard tool holder Ø 20 mm (also available for 3/4" shanks)

Return Spring

- Stable return spring for a safe closing of the blades after cleaning

Blades

- Long-lasting and resilient blade, even with a high volume of chips and cleaning operations

Design

- Slim design for space-saving storage in the tool magazine

Clean•Tec Technology

Small thing, great effect

With its simple but very efficient mode of operation,

the Clean•Tec Chip Fan has been convincing customers since 1999.

Calling up

Rinsing

Motion

Acceleration

Clearance

Unmanned Cleaning

Benefits of the Clean•Tec Chip Fan

Covinced by the benefits of the Clean•Tec Chip Fan?

Then simply use the contact form to ask for your indivdual quote.

Product overview

The “Originals”

The right size for every application

Clean•Tec 160

For targeted cleaning tasks such as blowing out pocket holes or bores

Clean•Tec 160

For targeted cleaning tasks such as blowing out pocket holes or bores

Clean•Tec 260

The all-rounder for general cleaning tasks

Clean•Tec 260

The all-rounder for general cleaning tasks

Clean•Tec 330

For high chip volume and large machine tables

Clean•Tec 330

For high chip volume and large machine tables

Success Stories

Start your own success story with Clean•Tec. This is what our customers have to say:

In combination with the RoboTrex Automation, the Clean•Tec is absolutely indispensable. Although our machine does not have the space for a medium, or large Clean•Tec, still even the small Clean•Tec with a diameter of 160 mm ensures us a fast and reliable cleaning of the machine interior after machining. Thanks to this small but important tool, we have no more large output from the machine and thus a higher level of cleanness inside and outside the machine. Of course, this also saves us time, as no employee must manually open and blow out the machine. An immensely important tool for us by now!

Sebastian Fetzer, Metallbau Fetzer GbR, 72584 Hülben, Germany

I can't believe we have gone so long without a Clean•Tec chip fan! This was a big game-changer for us. The fan blows off coolant and chips with ease. It is a must-have for large workpieces especially if it has deep pockets or geometry. Within seconds your work area is cleared of chips and coolant, eliminating the chances of you getting drenched in coolant or chips flying into your hand and face using compressed air. Using the Clean-Tec fan has been the most efficient way for a clean workspace in our machines. Awesome product.

Edgar Zamora, SouthWest Composites Works , Albuquerque New Mexico

Being a small operation we are always looking to invest in areas that make processes as efficient as possible. The Clean•Tec fans were originally purchased as a means of cleaning down parts & pallets at the end of cycles but we soon realized we were able to increase process reliability and perform cleaning cycles to remove swarf from roughing operations. This improved tool life drastically and we have never looked back - we use 160 mm & 260 mm diameters fans in our machines and they never leave the tool carousel.

Ed Ratcliffe, Ratworks Engineering, UK

I was truely astonished at how powerful the Lang chip fan is, we have the 260mm fan and use it in our machining centres to clear swarf and coolant from parts and jig plates at the end of operations. This has cut our change over times in half on some jobs as it’s removed the need to do it by hand with an air gun.. it really was a great investment

Jack Morris, Myriad Engineering Ltd.

Clean•Tec in use

Making childrens lives better with Clean•Tec

For years, LANG Technik has been supporting the BILD hilft e.V. "Ein Herz für Kinder" foundation. With every Chip Fan sold, 2 € are donated to "Ein Herz für Kinder".

Already donated

You want to keep your machine tool clean?

Product overviewLearn more about other solutions by LANG

RoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

More detailsQuick•Point® Zero-Point Clamping System

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

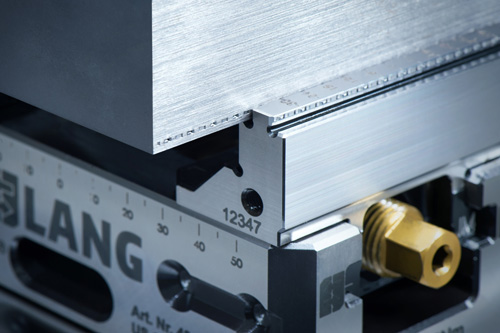

More detailsQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

More detailsMakro•Grip® Raw Part Clamping and Stamping Technology

Clamping parts by form-closure – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

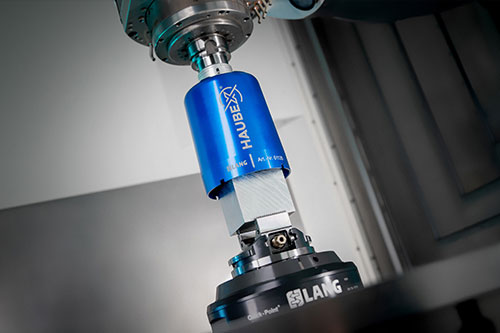

More detailsHAUBEX Automation System

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vise and workpiece blank.

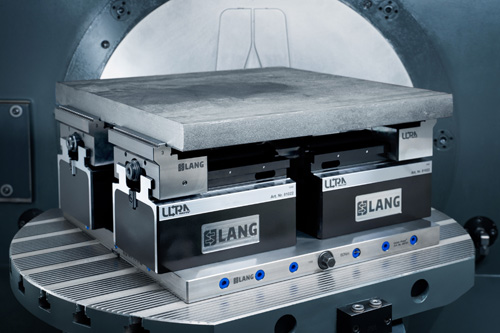

Learn moreMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

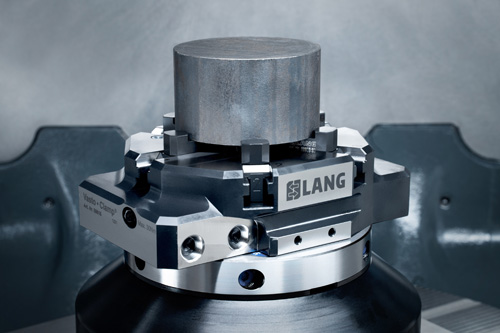

More detailsConventional Workholding

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

More details