The world’s most simple automation solution

What is HAUBEX?

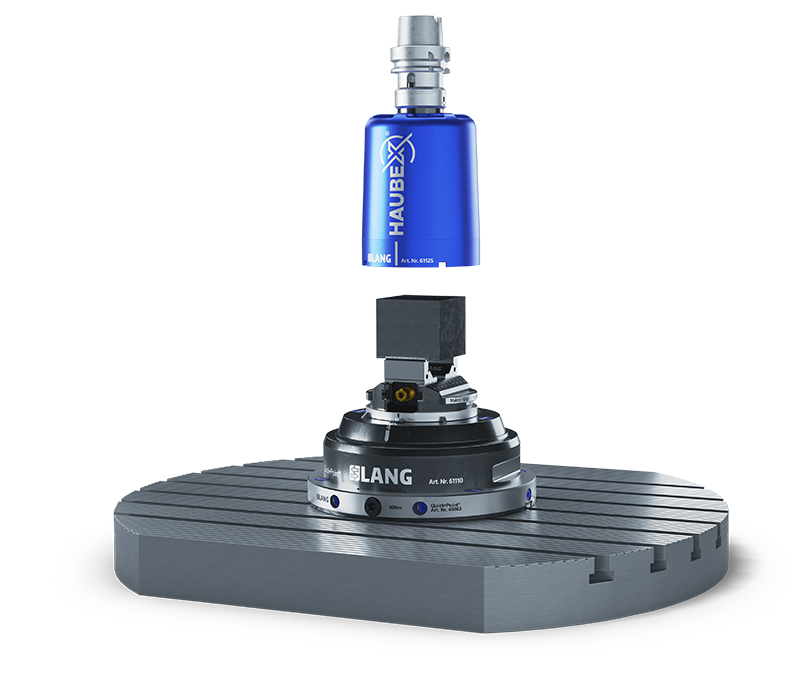

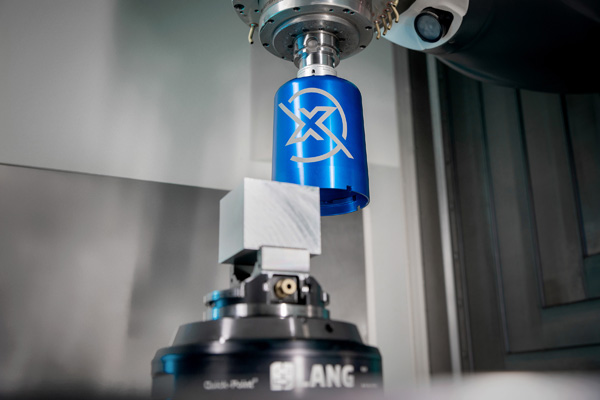

HAUBEX is a flexible and cost-effective automation solution for small batches from batch size 2 that transforms the tool magazine into an automation system. The heart of HAUBEX is a workholding hood, which serves as a carrier system for the clamping device and the workpiece blank and is stored in the tool magazine.

What is HAUBEX used for?

HAUBEX makes it easy to increase efficiency in your manufacturing by productively filling breaks, creating additional time windows for alternative, value-adding activities or extending working hours by allowing the machine tool to continue unmanned production after the end of work.

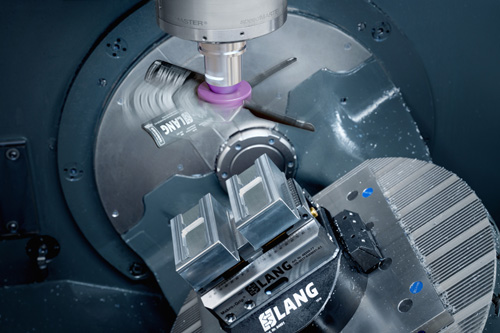

HAUBEX – The automatic vise change from the tool magazine

In joint cooperation, Erst Maschinenbau and LANG Technik present a patented system with which every machine tool can manufacture automatically without an additional feeding unit or robot - innovative. patented. unique.

HAUBEX

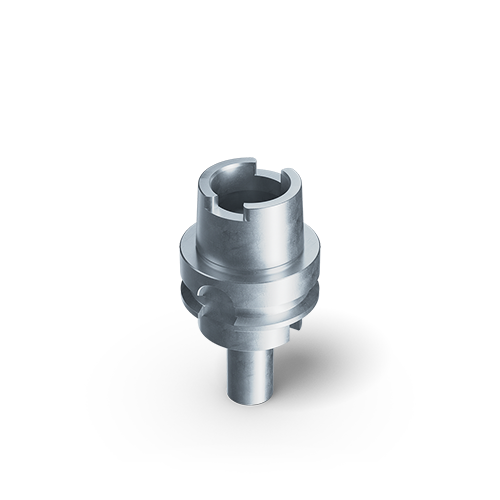

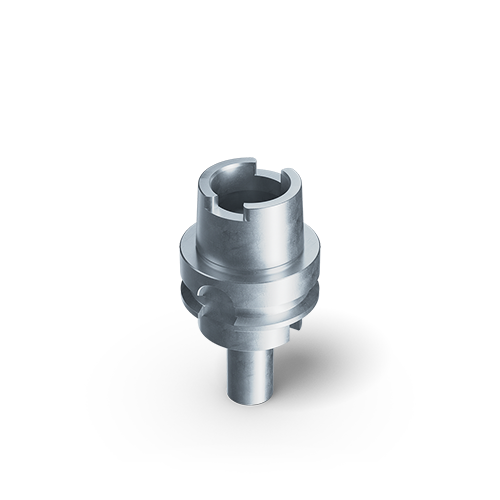

tool holder

- The tool holders type HSK-A63, SK 40 and BT 40, which are suitable for HAUBEX, guarantee an exactly defined positioning of the workholding hood in the machine spindle.

HAUBEX

workholding hood

- Anodized aluminium hood as a carrier system for the clamping device and the workpiece blank

- Locks and opens the zero-point clamping system by 90° closing movement

- Safety element between workholding hood and tool holder as a buffer and spindle protection

- Integrated guide and fixation secures the clamping device against unintentional release from the workholding hood and ensures a secure fit

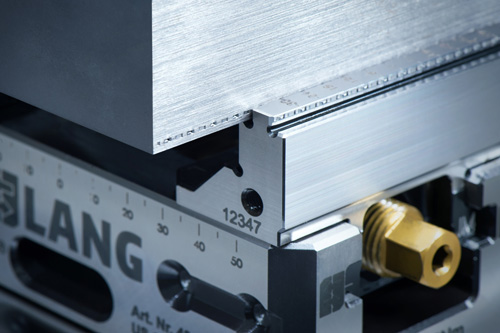

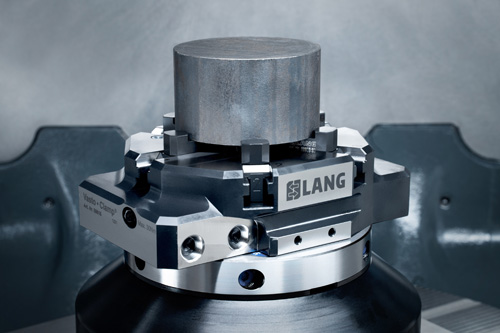

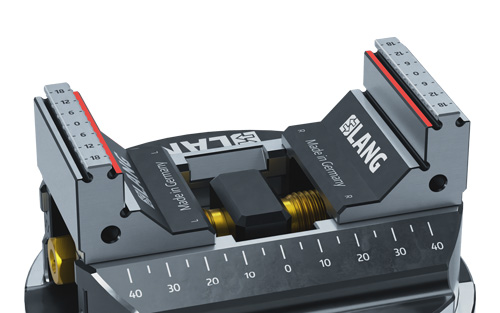

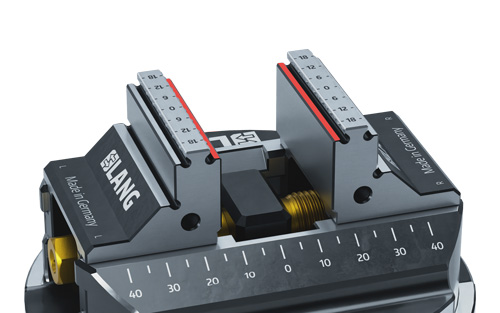

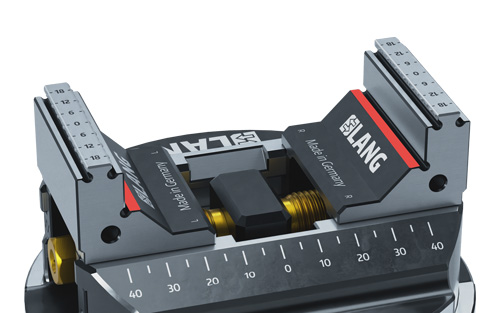

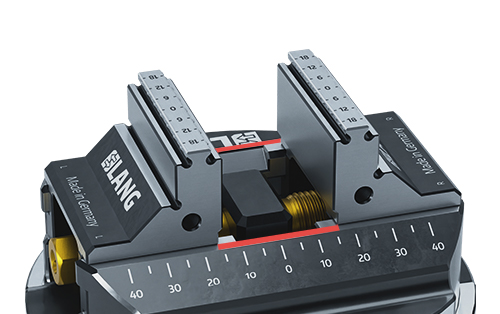

Makro•Grip® HAUBEX

5-Axis Vise

- 5-Axis Vise with proven Makro•Grip® technology for highest holding forces and process reliability

- Jaw width 46 mm in slim design for ideal accessibility in 5-sided machining

- Maximum workpiece blank dimensions: approx. 80 x 75 x 70 mm, depending on height and diameter of workholding hood. Examples of maximum possible dimensions are available in the download area.

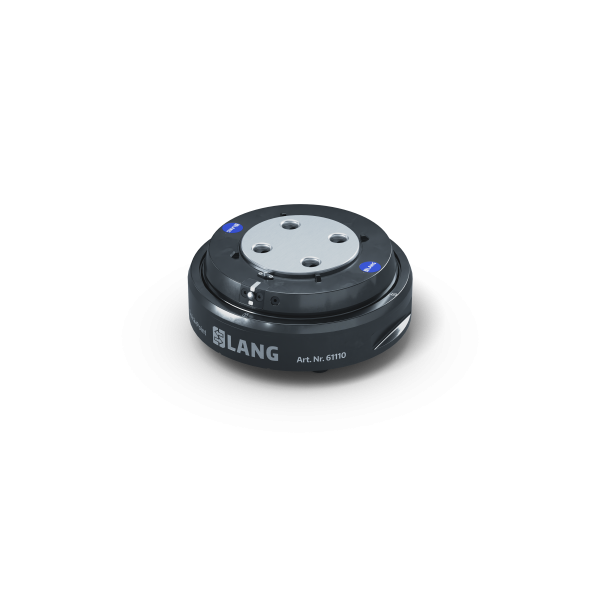

Quick•Point® HAUBEX

zero-point clamping system

- Mechanically operated zero-point device with patented clamping mechanism

- Actuated automatically via workholding hood or manually via clamping lever

- Equipped with clamping studs for fast set-up in the Quick•Point® zero-point clamping system

- Including carrying handle and clamping lever for manual operation

HAUBEX Technology

Benefits of HAUBEX

Convinced by the benefits of the HAUBEX automation system?

Then simply use the contact form to ask for your individual quote.

View products

How to use HAUBEX

In just a few steps you can turn

your tool magazine into an automation system

Workpiece clamping

Equipping the workholding hood

Measuring and program sequence

Vise storage

Clamping mechanism

Cleaning

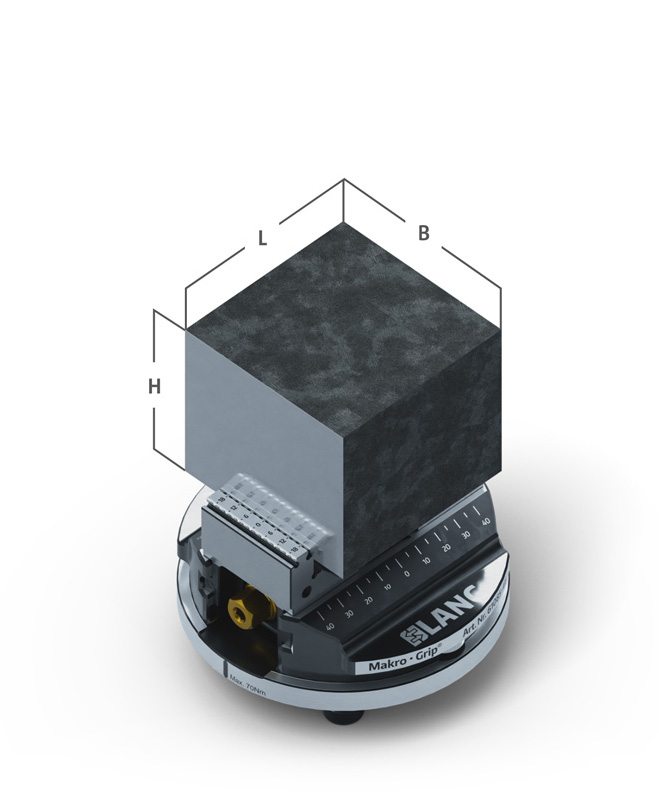

Workpiece size generator

Does my workpiece blank meet the requirements for automatic manufacturing with HAUBEX? Find out now with the HAUBEX Workpiece Size Generator!

Workpiece Dimensions

Mouseover over the display on the right indicates the respective workpiece edge.

Mouseover over the display on the right indicates the respective workpiece edge.

Material

Tool Holder

Result

The workpiece dimensions you have entered allow automated manufacturing with HAUBEX. (Attention: In addition, please check the allowable load of your tool magazine).

Unfortunately, automated manufacturing with HAUBEX is not possible with the workpiece dimensions you have entered.

possible

not possible

Unfortunately, the combination of values you entered from L x W x H is not possible. Please try again with other values. For further information on calculating the maximum allowable workpiece size, please click here. If you have any questions in this regard, please do not hesitate to call LANG Technik or the sales partner responsible for you.

Specifications

*Weight of tool holder, workholding hood, workpiece and 5-Axis Vise.

Please check that the calculated total weight does not exceed the allowable load of your tool magazine.

Your workpiece can be clamped in the 5-Axis Vise as follows

(support surface marked in red):

Your parts fit under the hood? Then use our contact form and let us make you a concrete offer.

Product overviewServing something special

All components of HAUBEX at a glance

Quick•Point® HAUBEX

Zero-Point Clamping System

Makro•Grip® HAUBEX

5-Axis Vise

HAUBEX

Workholding Hood

HAUBEX

Tool Holders

HSK-A63

HAUBEX

Tool Holders

SK-40

HAUBEX

Tool Holders

BT-40

HAUBEX

Tool Holders

CAT 40

Erfolgsgeschichten

Start your own success story with HAUBEX. This is what our customers say:

Thanks to our many years of consistently positive experience with LANG workholding systems, we considered HAUBEX to give us more flexibility in production. With HAUBEX, we wanted to open up the possibility of producing small series unmanned and automating regularly recurring work. We currently produce up to 6 hours on our 5-axis machine during the day, while the machine operator can take care of other tasks during this time. After work, the machine runs for another 6 hours. We also use HAUBEX on a lesser-used 3-axis machine, enabling us to prefabricate regularly required parts with consistently high quality and much lower personnel and machine costs. It has turned out that HAUBEX harmonizes very well with all our control systems.

Marco Hoßfeld, Sensus GmbH, 67063 Ludwigshafen am Rhein

HAUBEX in use

Automate with any machine tool in your

production? Get your HAUBEX now!

View products

Learn more about other solutions by LANG

RoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

More detailsQuick•Point® Zero-Point Clamping System

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

More detailsQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

More detailsMakro•Grip® Raw Part Clamping and Stamping Technology

Clamping parts by form-closure – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

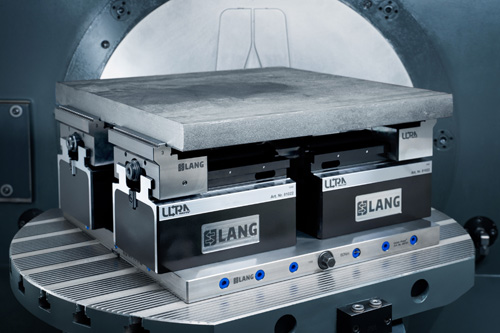

More detailsMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

More detailsConventional Workholding

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

More detailsClean•Tec Chip Fan

The chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

More details