Conventional Workholding

Diverse clamping solutions for milling round or pre-machined components

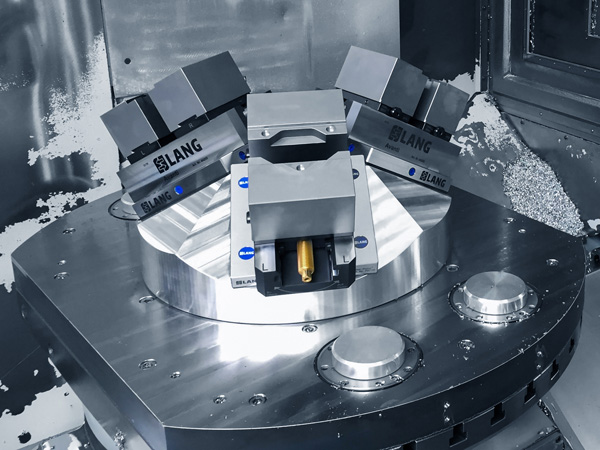

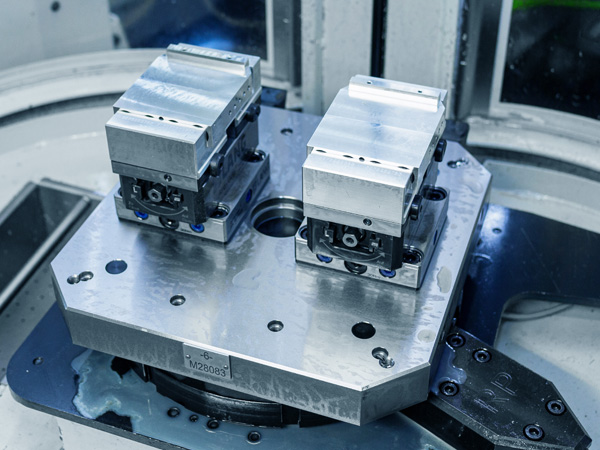

While the strengths of Makro•Grip® stamping technology and the 5-Axis Vises are mainly seen in the processing of unmachined parts, workholding devices of the „Conventional Workholding“ category offer various options for smooth clamping of round or pre-machined components. To solve the respective clamping task, a 6-jaw chuck, two collet chucks and a total of three different types of centering vises are available to the operator.

They differ only in the type of their clamping jaws. They use the same base body as the Makro•Grip® 5-Axis Vise, which ensures consistent compatibility and interchangeability. The different types of jaws of the „Conventional Workholding“ are ideally suited for demanding rear-face machining tasks and perfectly complement the 5-Axis Vise in order to machine all faces of a workpiece.

Workholding devices

Vario•Tec for (semi-)finished parts

- Centering vise with pin jaw system

- For (semi-) finished, cubic parts

- Support system makes parallels obsolete

Avanti for pre-machined parts

- Flexible clamping solution for round and pre-machined parts

- Quick jaw exchange with just one screw

- Unbeatable low purchasing costs for top jaws

Vasto•Clamp for milling operations

- 6-jaw chuck for milling operations

- For machining of blanks and for parts sensitive to deformation

- Innovative quick jaw exchange system

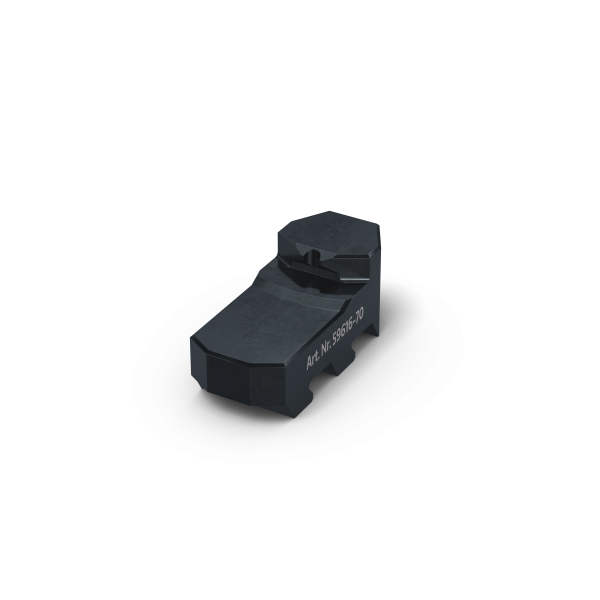

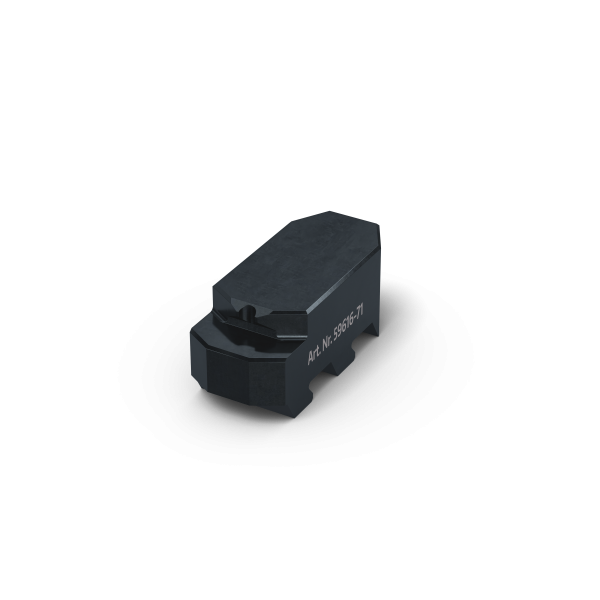

Profilo for pre-machined parts

- Centering vise with soft machinable top jaws

- Flexible clamping solution for contours and pre-machined parts

- In-house production of top jaws possible

Preci•Point for round part clamping

- Collet chucks for milling

- For clamping round parts up to Ø 34 mm

- Use of commercially available collets

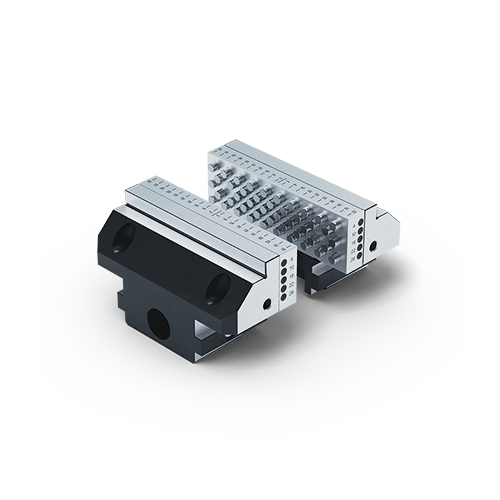

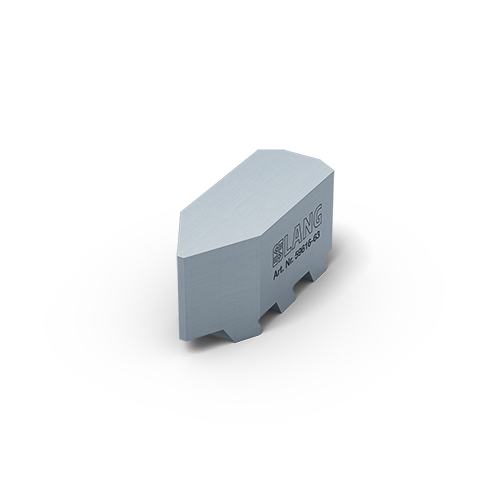

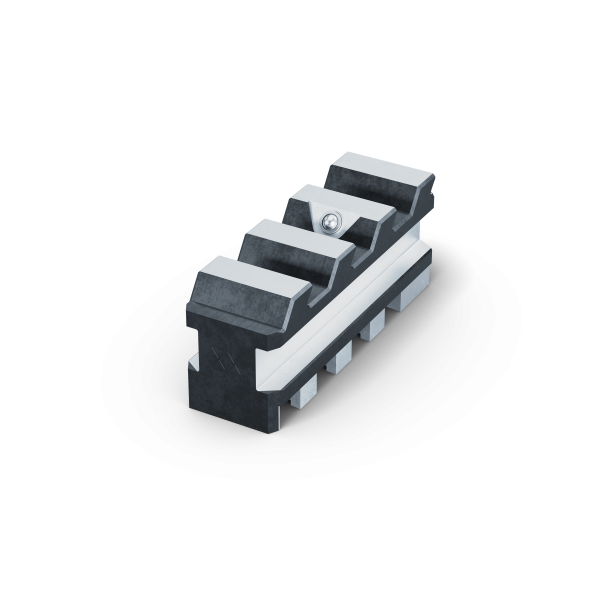

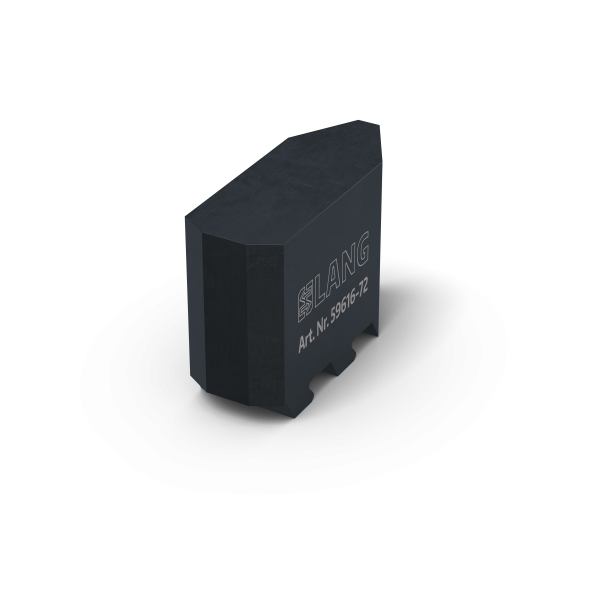

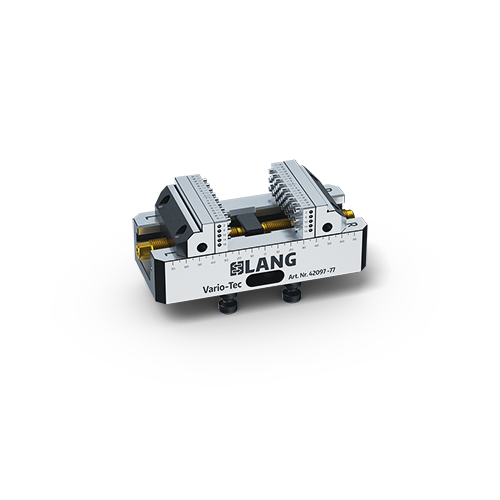

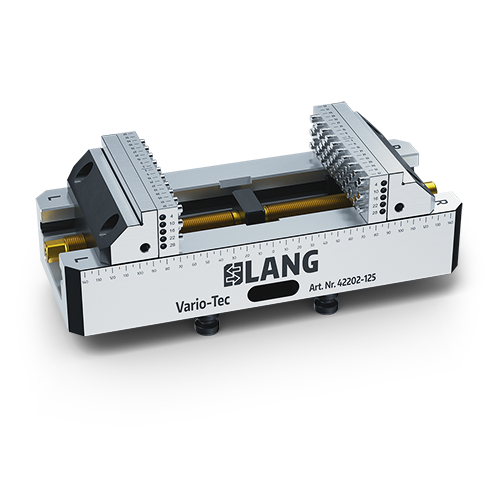

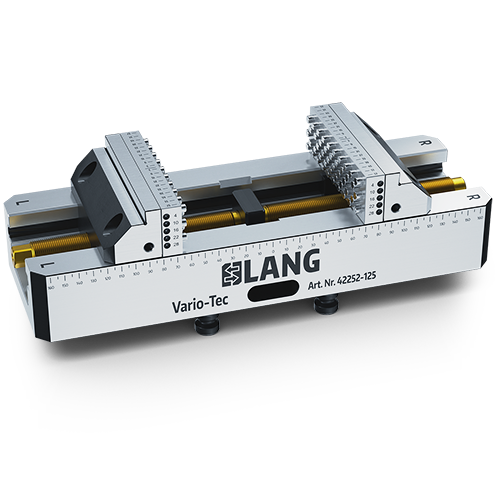

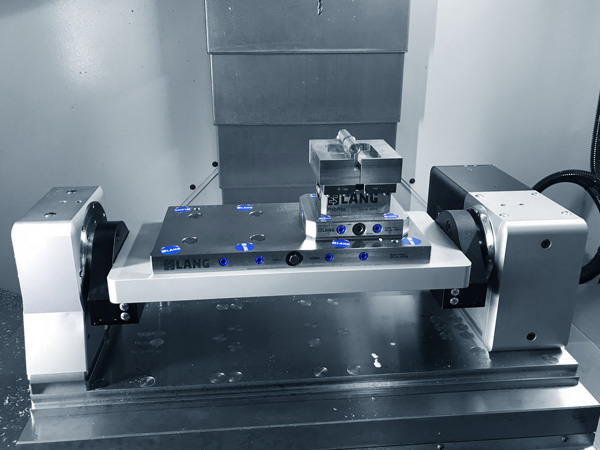

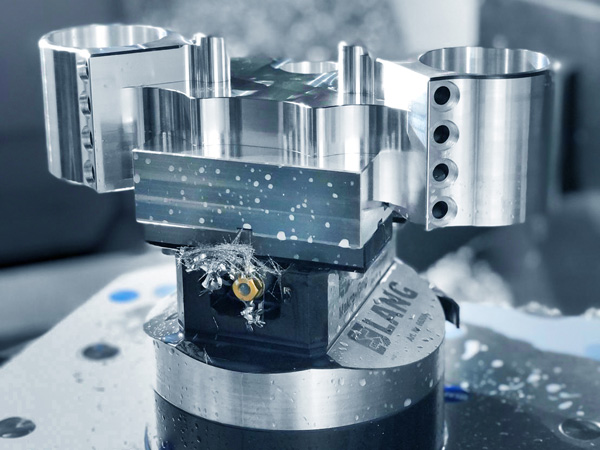

Vario•Tec

The convenient and versatile clamping solution for (semi-) finished parts

- Precise positioning of workpieces and reproducibility of clamping situation

- High degree of machining flexibility

- Quick and simple adjustment of desired configuration

- Parallels and end stops are not needed

Lateral bores

- Pins are blown out row by row with compressed air

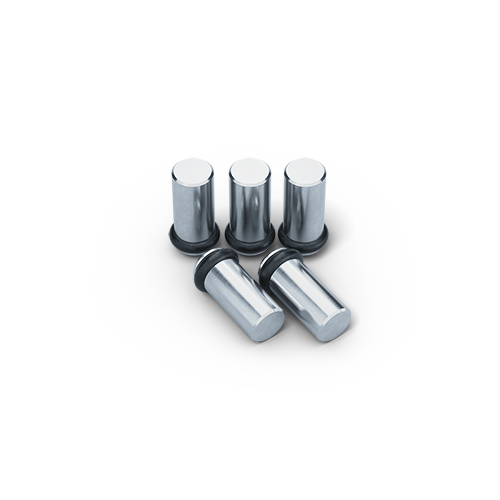

Pins

- Stop and support system for workpieces. Pushed back by hand if not needed. Positioning accuracy ± 0,01 mm

Carrier jaw

- Double guided jaws for an increased stiffness and parallelism

Zero-point interface

- Integrated with clamping studs for precise clamping in the Quick•Point® zero-point system

Base body

- Stable and robust base body made of hardened steel

Vario•Tec Technology

Products

Technical Data

Vario•Tec 77

Clamping range up to 57 mm

Vario•Tec 77

Clamping range up to 97 mm

Vario•Tec 77

Clamping range up to 137 mm

Vario•Tec 125

Clamping range up to 100 mm

Vario•Tec 125

Clamping range up to 150 mm

Vario•Tec 125

Clamping range up to 200 mm

Vario•Tec 125

Clamping range up to 250 mm

Convinced by Vario•Tec?

Then simply use the contact form to ask for your indivdual quote.

Product overview

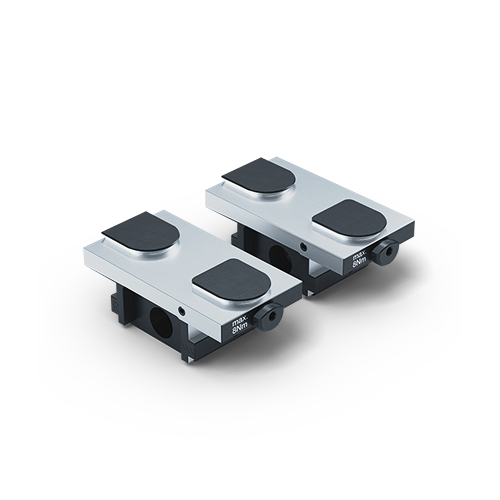

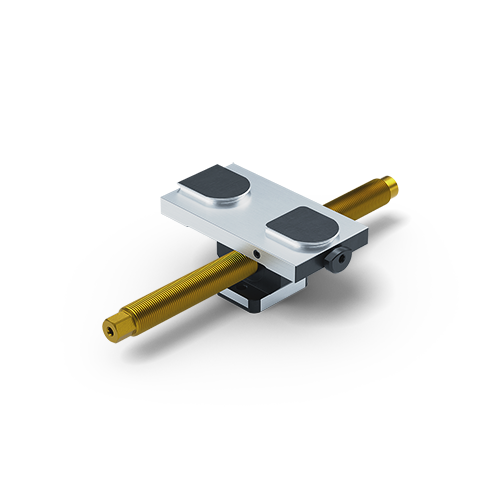

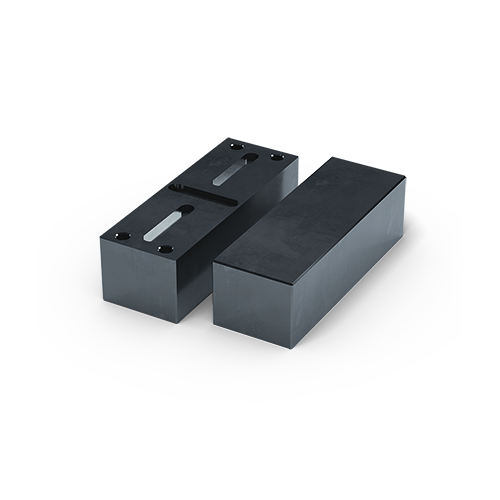

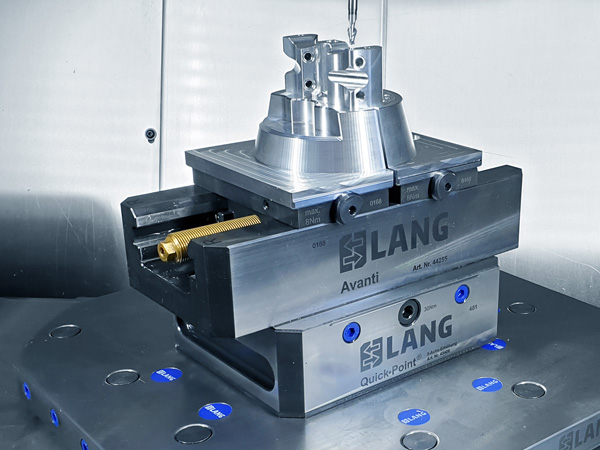

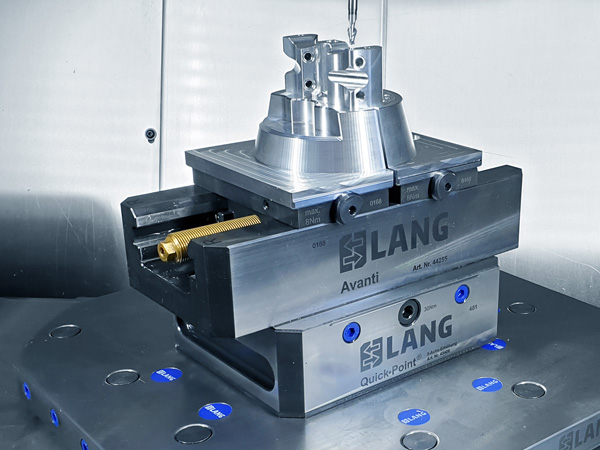

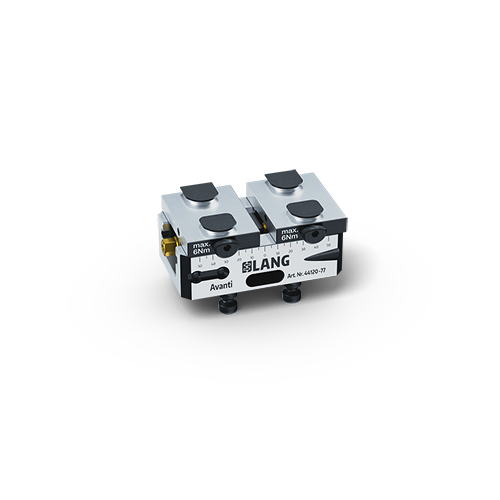

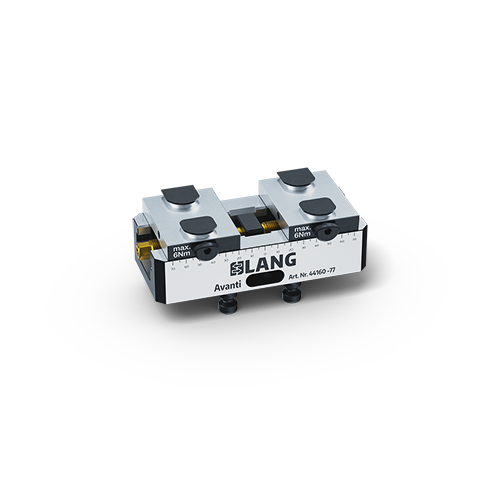

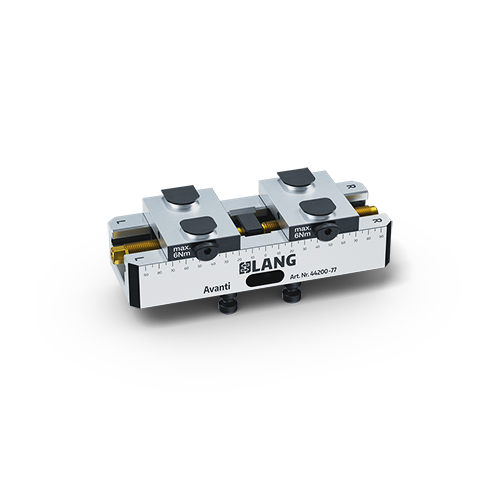

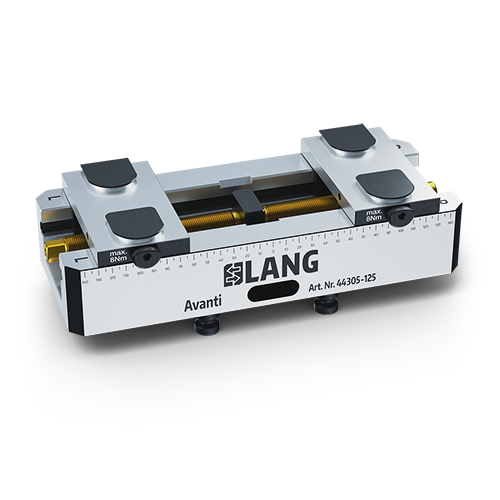

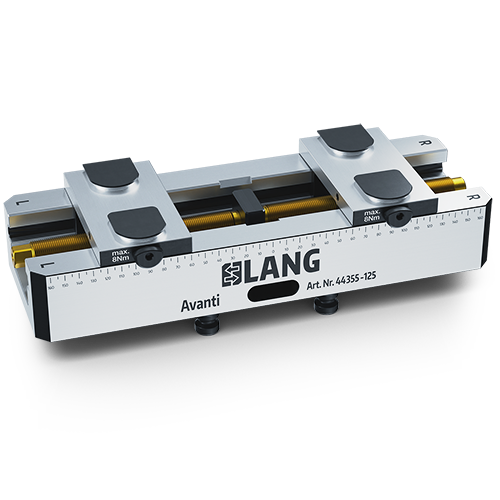

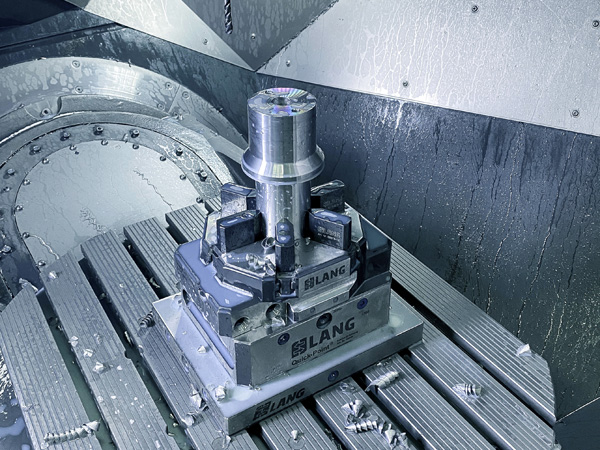

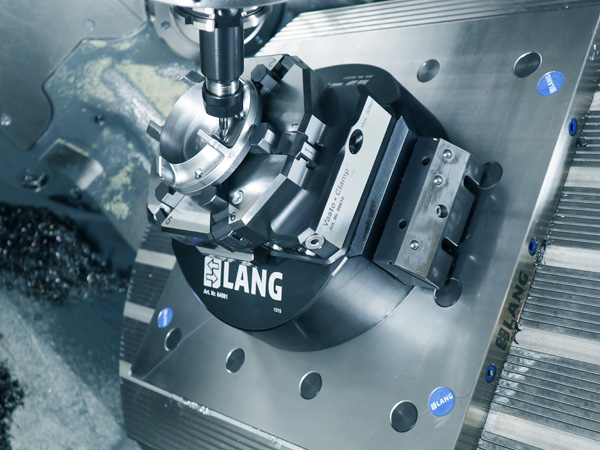

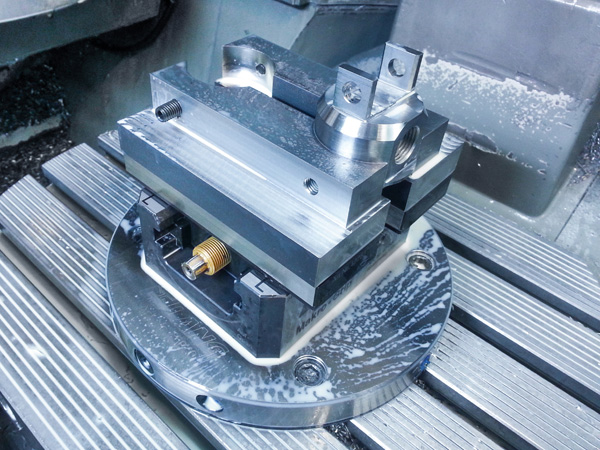

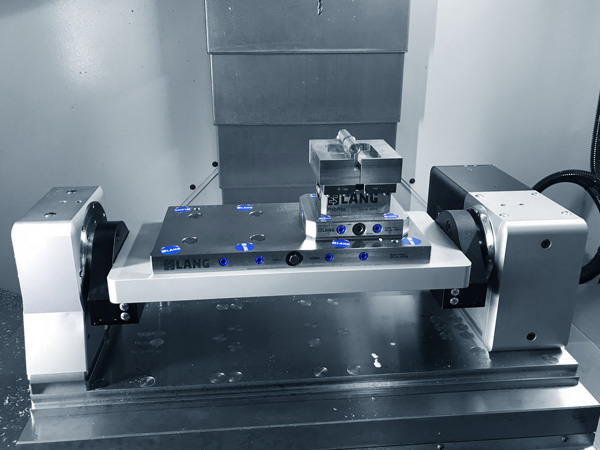

Avanti

The universal vise with great handling characteristics and extremely fast jaw exchange

- Flexible clamping solution for round and pre-machined parts

- Quick jaw exchange with just one screw

- Unbeatable low purchasing costs for top jaws

- High-precision positioning of top jaws thanks to the patented interface

Positioning of top jaws

- Patented interface ensures precise positioning of top jaws

Mounting of top jaws

- Quick jaw exchange with just one screw

Top jaws

- Large-volume steel or aluminium top jaw allows several contours to be added

Zero-point interface

- Integrated with clamping studs for precise clamping in the Quick•Point® zero-point system

Base jaw

- Double guided jaws for increased stiffness and parallelism

Base body

- Rigid and sturdy base body – but still lightweight and handy

Avanti Technology

Avanti applications

Products

Technical Data

Avanti 77, jaw width 46 mm

Clamping range up to 102 mm

Avanti 77, jaw width 46 mm

Clamping range up to 130 mm

Avanti 77, jaw width 77 mm

Clamping range up to 130 mm

Avanti 77, jaw width 77 mm

Clamping range up to 170 mm

Avanti 77, jaw width 77 mm

Clamping range up to 210 mm

Avanti 125, jaw width 125 mm

Clamping range up to 210 mm

Avanti 125, jaw width 125 mm

Clamping range up to 260 mm

Avanti 125, jaw width 125 mm

Clamping range up to 310 mm

Avanti 125, jaw width 125 mm

Clamping range up to 360 mm

Single components

All vise types use the same base body in different lengths and jaw widths. This guarantees that all jaw types are interchangeable and compatible to each other. Working with one base body and two or more jaw types ensures even more efficiency with low resource investment!

Avanti vs Profilo

Profilo

Avanti

46 / 77 / 125

Convinced by Avanti?

Then simply use the contact form to ask for your indivdual quote.

Product overview

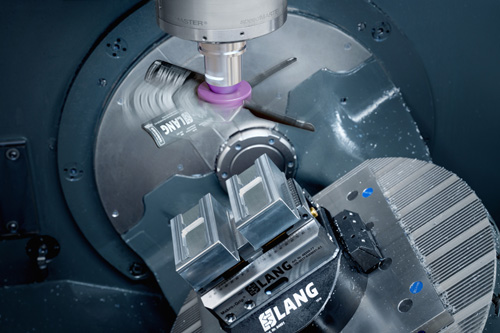

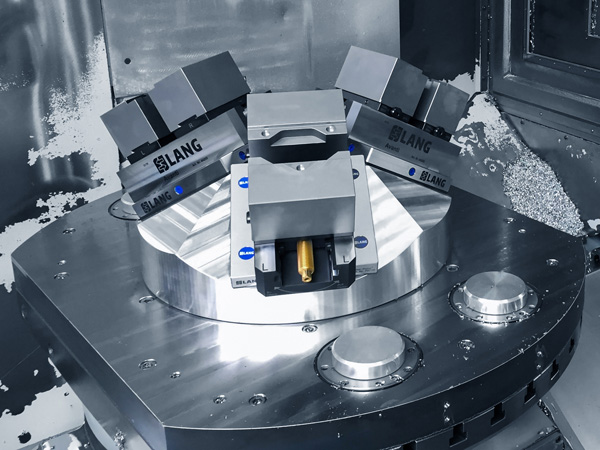

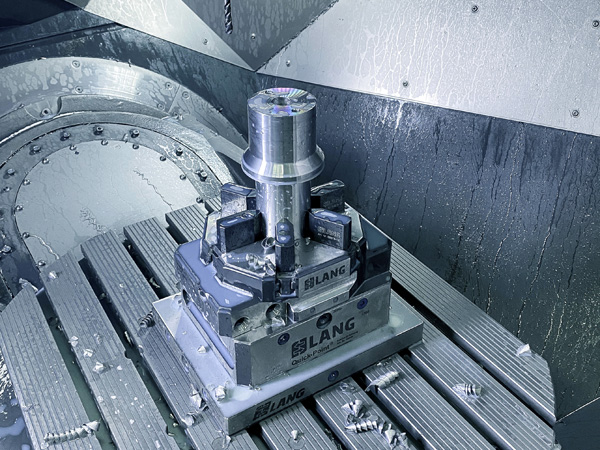

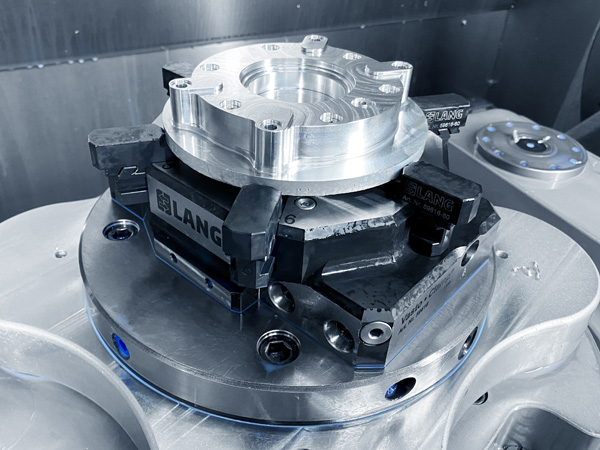

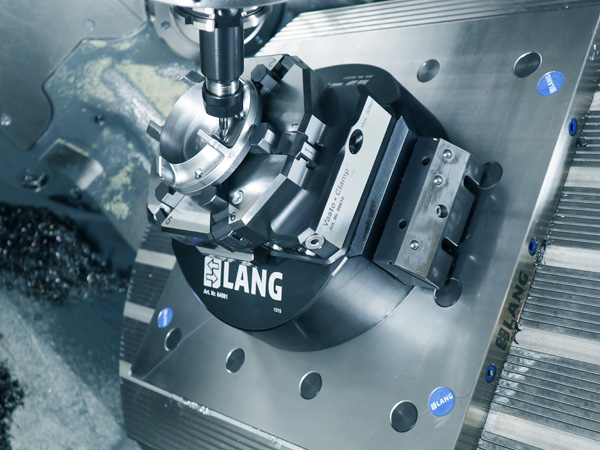

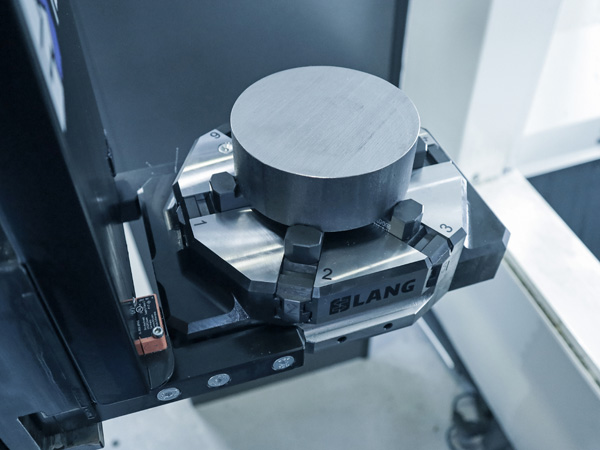

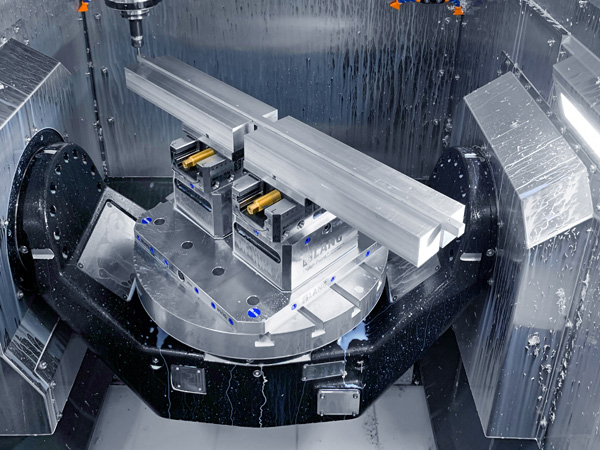

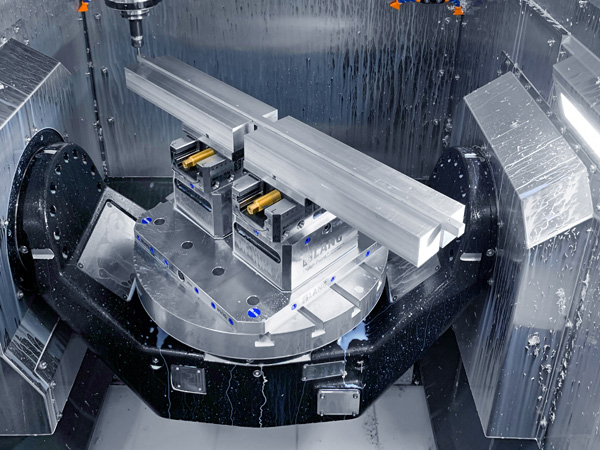

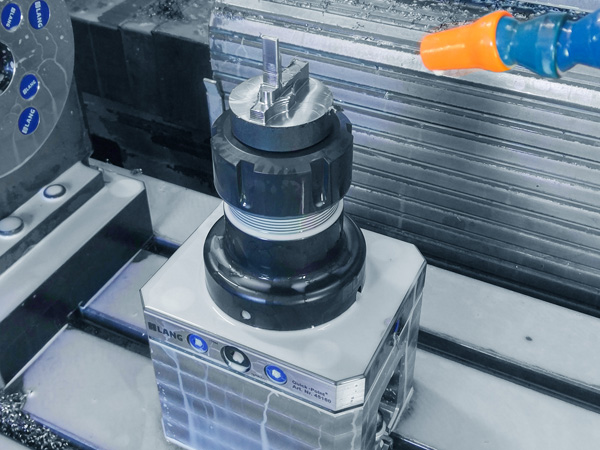

Vasto•Clamp

The versatile 6-jaw chuck with quick exchange system

- The versatile 6-jaw chuck with quick exchange system

- Innovative click mechanism for a quick jaw exchange without the use of any tools

- Suitable for clamping of raw parts and components sensitive to deformation

- Flexibly usable as a 2-, 3- or 6-jaw chuck, both O.D. clamping and I.D clamping possible

Base jaw

- Hardened base jaw with innovative click mechanism

- Also available for I.D. clamping

Top jaws

- Made of steel (hardened or soft) or aluminium (soft) for clamping ranges up to Ø 160 mm

Gripper interface

- Automatable thanks to integrated gripper interface

Zero-point interface

- Integrated with clamping studs for precise clamping in the Quick•Point® zero-point system

Base body

- Stable and robust base body made of hardened steel

- Possibility for through hole up to Ø 38 mm

Vasto•Clamp Technology

Vasto•Clamp applications

Products

Technical Data

Vasto•Clamp

Clamping range up to 160 mm

Single components

Convinced by Vasto•Clamp?

Then simply use the contact form to ask for your indivdual quote.

Product overview

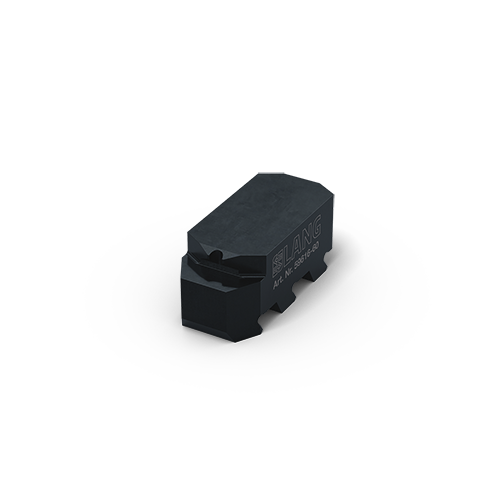

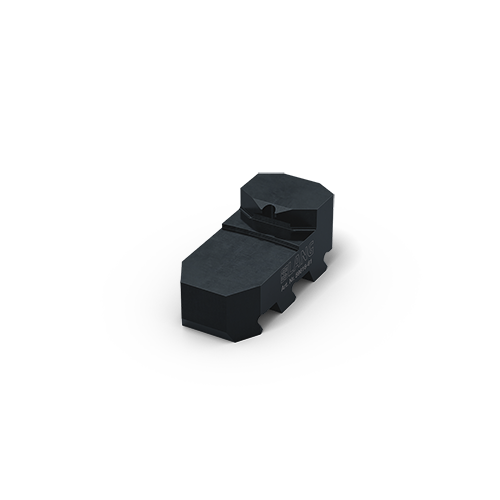

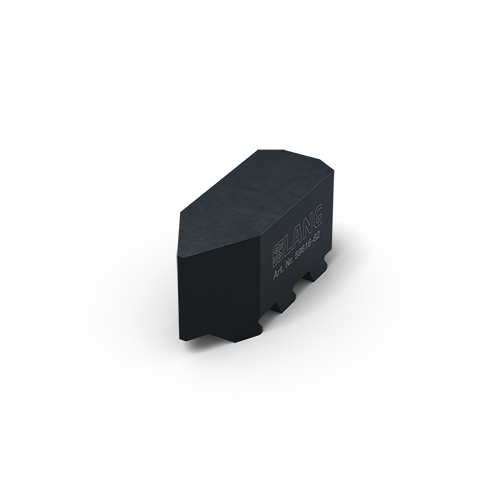

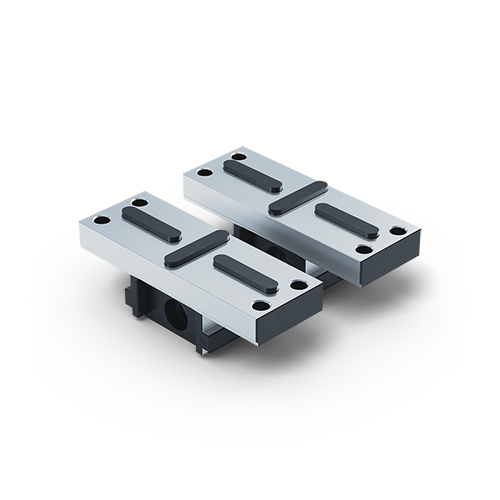

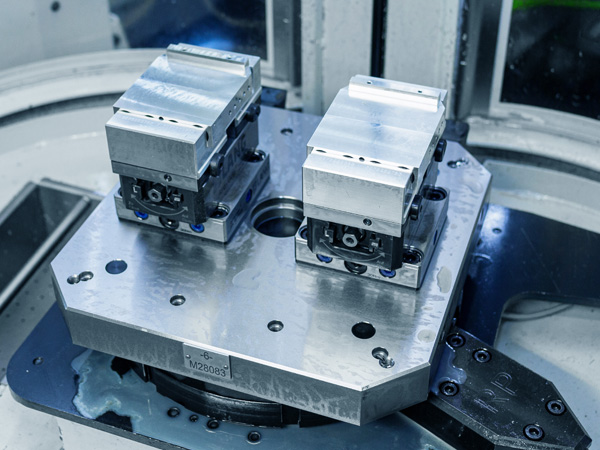

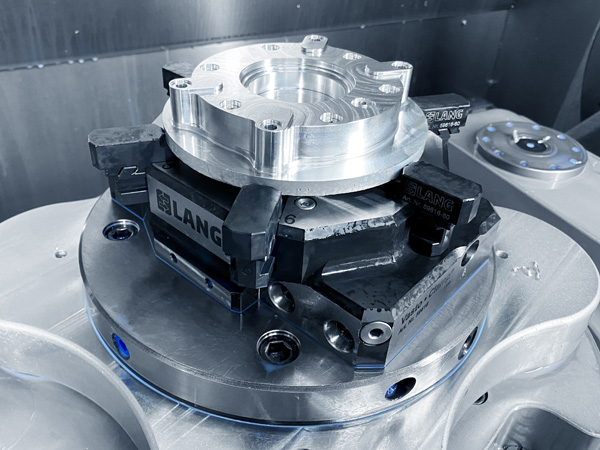

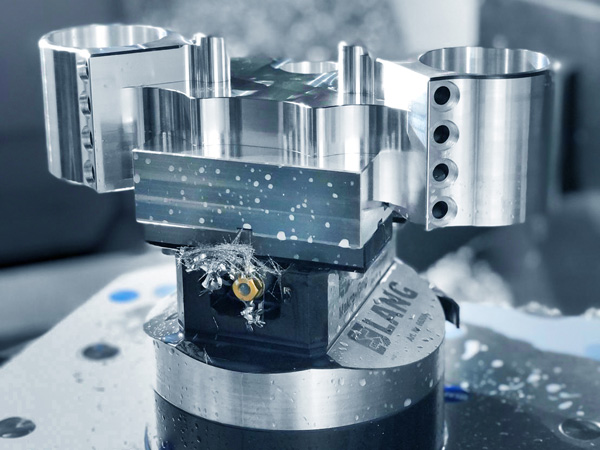

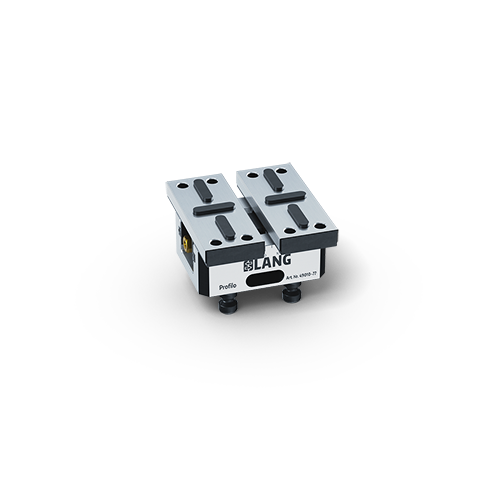

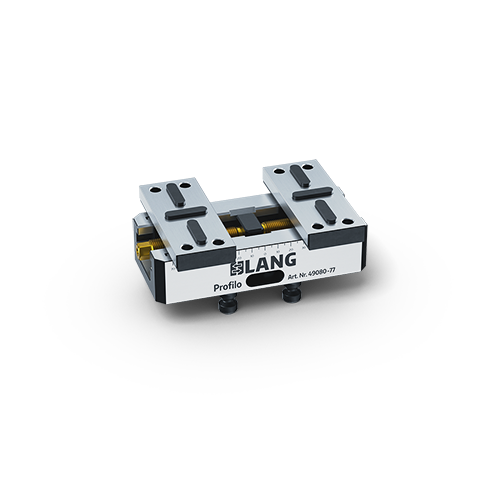

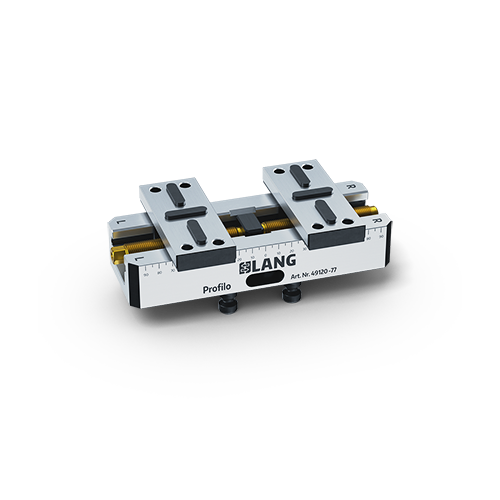

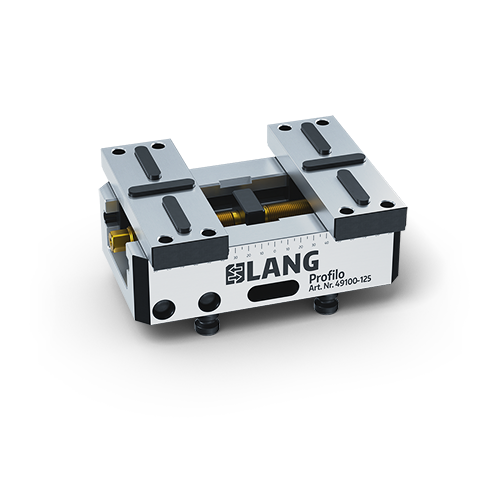

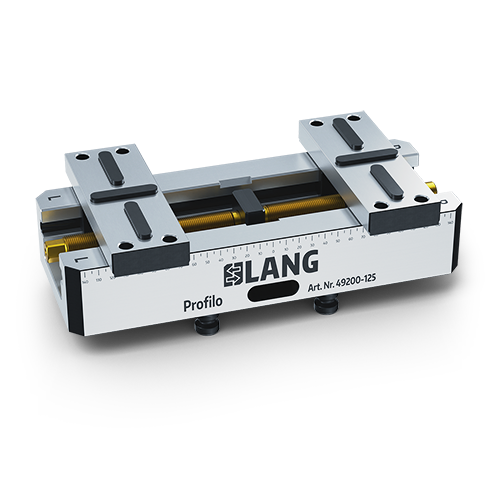

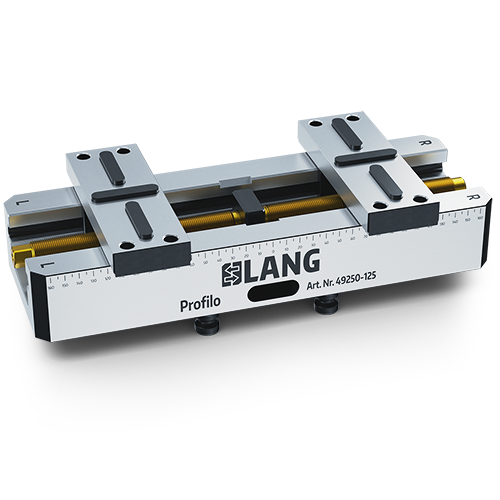

Profilo

The versatile clamping system for all round or pre-machined parts

- High flexibility as top jaws can be manufactured in-house

- Robust connection between base and top jaws with screws

- Mounting of top jaws from beneath or from the top

Interface to the top jaw

- Positioning of the top jaws via feather keys in the base jaws

Mounting of top jaws

- Robust interface between base and top jaw thanks to 4 fastening screws

Top jaws

- Large-volume steel or aluminium top jaw allows several contours to be added

Zero-point interface

- Integrated with clamping studs for precise clamping in the Quick•Point® zero-point system

Base jaws

- Double guided jaws for an increased stiffness and parallelism

Base body

- Stable and robust base body made of hardened steel

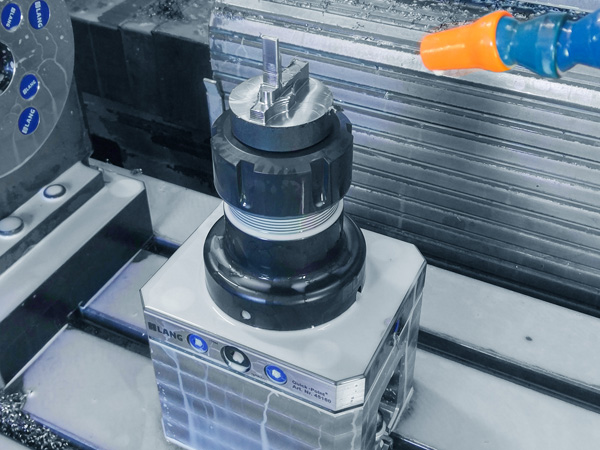

Profilo Technology

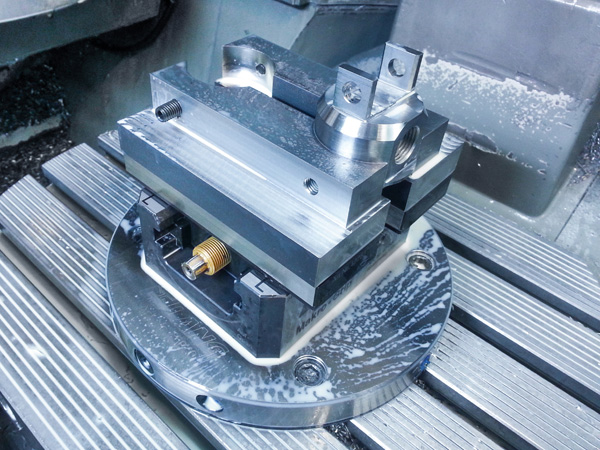

Profilo applications

Products

Technical data

Profilo 77

Clamping range up to 102 mm

Profilo 77

Clamping range up to 130 mm

Profilo 77

Clamping range up to 170 mm

Profilo 77

Clamping range up to 210 mm

Profilo 125

Clamping range up to 160 mm

Profilo 125

Clamping range up to 210 mm

Profilo 125

Clamping range up to 260 mm

Profilo 125

Clamping range up to 310 mm

Profilo 125

Clamping range up to 360 mm

Single components

All vise types use the same base body in different lengths and jaw widths. This guarantees that all jaw types are interchangeable and compatible to each other. Working with one base body and two or more jaw types ensures even more efficiency with low resource investment!

Profilo vs. Avanti

Profilo

Avanti

46 / 77 / 125

Convinced by Profilo?

Then simply use the contact form to ask for your indivdual quote.

Product overview

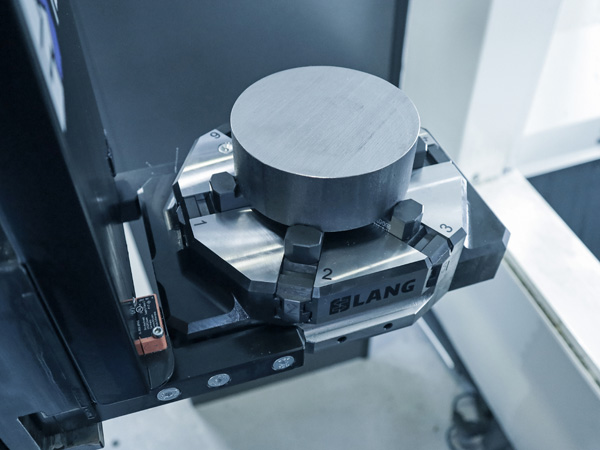

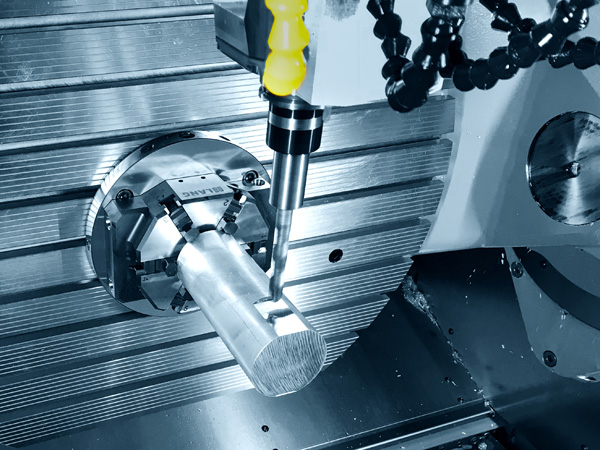

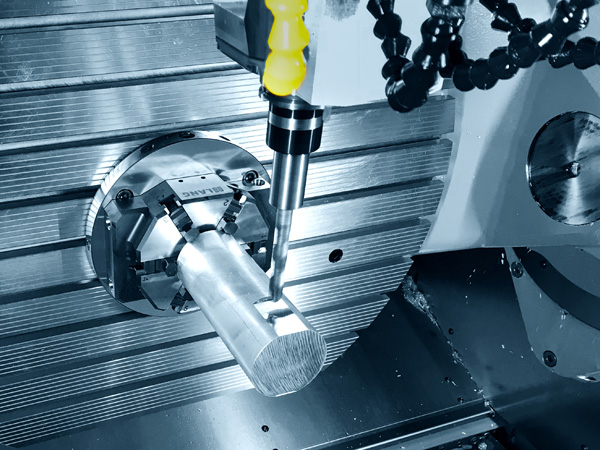

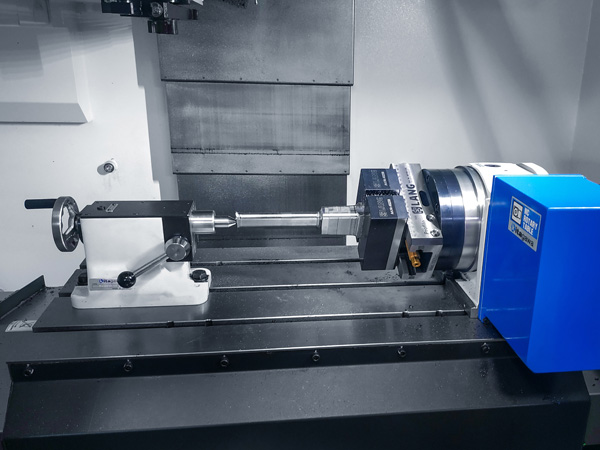

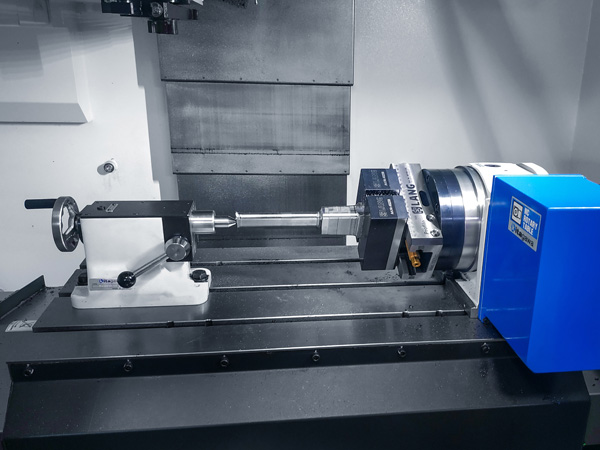

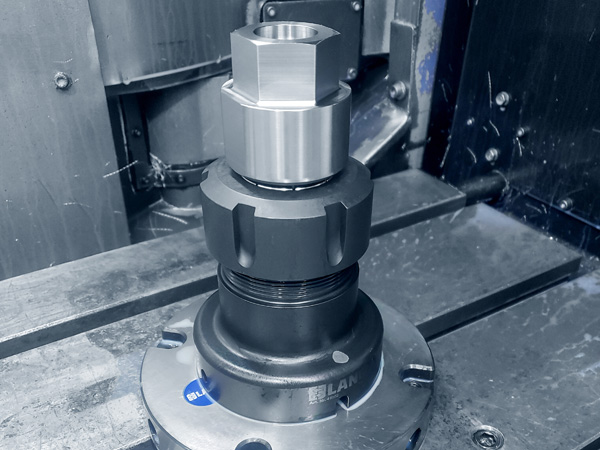

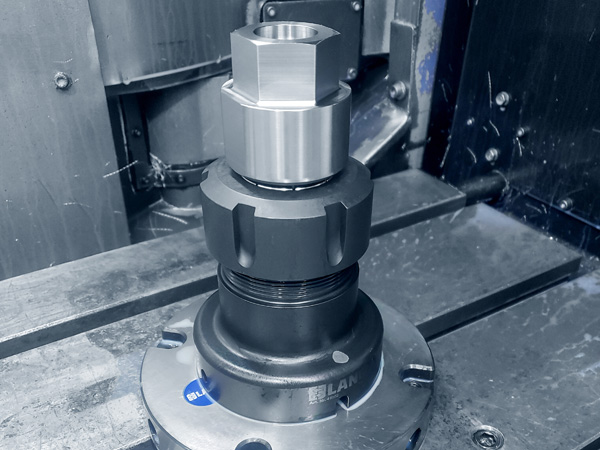

Preci•Point

The compact collet chuck for milling round parts

- Slim design ensures great accessibility

- Utilization of commercially available ER 32 and ER 50 collets

- Clamping ranges of Ø 3 mm to Ø 34 mm

- Integrated zero-point interface allows quick set-up

Collets

- Utilization of commercially available ER 32 and ER 50 collets

Workpiece end stop

- M6 tapped hole enables the use of a workpiece end stop

Zero-point interface

- Integrated with clamping studs for precise clamping in the Quick•Point® zero-point system

Base body

- Robust base body made of hardened and coated steel

Preci•Point Technology

Preci•Point applications

Products

Technical data

Preci•Point 52

for ER 32 collets

Preci•Point 52

for ER 50 collets

Convinced by Preci•Point?

Then simply use the contact form to ask for your indivdual quote.

Product overview

Benefits of Conventional Workholding

Minimal time required for set-up

Simple and user-friendly operation

Enormous flexibility due to the possibility of using different top jaws

Diverse clamping solutions for differently shaped parts

All centering vise jaw types compatible with the Makro•Grip® 5-Axis Vise

Precise and robust mounting between base and top jaws

Convinced by the benefits of „Conventional Workholding“? Then simply use the contact form to ask for your indivdual quote.

Product overviewSuccess Stories

Start your own success story with „Conventional Workholding“ solutions by LANG. This is what our customers have to say:

Recently, we have seen an increase in the number of cylindrical blanks that have to be produced on our 5-axis machines and have decided to use the new Vasto•Clamp. We have been using the Vasto-Clamp for some time and have been able to reduce set-up times with the click jaw system. With parts that are not completely cylindrical, the 6-jaw chuck makes it possible to remove a top jaw without any problems and still clamp parts flat. Eccentric clamping is also child's play thanks to the click jaws. Whether raw parts or precise clamping with pre-machined jaws for thin-walled components, the 6-jaw chuck clamps safely and without deformation. Due to its shape, the Vasto•Clamp is more accessible than conventional jaw chucks.!

Manuel Dengler, Dengler CNC-Technik

The Avanti vises in connection with aluminium top jaws are our first choice when it comes to clamping parts for which a special machined contour is required. Since the top jaws are held securely from below by a special interface, there are no annoying screws, pins or clamps. We also do not waste any machinable space in the top jaws, because there are no holes or counter bores. This means that the entire jaw volume can be used to machine the required contour. In addition, the good accessibility from all sides due to the lack of interfering areas, as well as the fast and acurate jaw exchange, makes the Avanti the most widely used vice for seconds operations in our shop.

Sebastian Thoma, Thoma-Tec, 84155 Bodenkirchen

We mainly use the Preci•Point to clamp pre-turned components that contain precise 3D contours after machining on the 5-axis machines. Due to its slim design, parts can be clamped with low vibration. Accessibility with shorter tools is also better than with common competitor products.

Manuel Dengler, Dengler CNC-Technik

Are you looking for flexible and versatile clamping systems for your diverse range of parts?

Product overviewLearn more about other solutions by LANG

RoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

More detailsQuick•Point® Zero-Point Clamping System

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

More detailsWerkstückspanntechnik

LANG Technik steht für modulare Spanntechnik, die sich flexibel an unterschiedliche Werkstücke, Bearbeitungsstrategien und Automatisierungsgrade anpasst

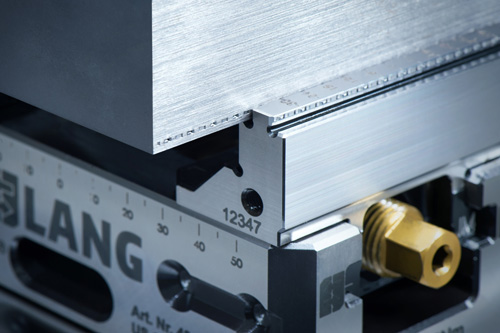

Mehr erfahrenQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

More detailsMakro•Grip® Raw Part Clamping and Stamping Technology

Clamping parts by form-closure – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

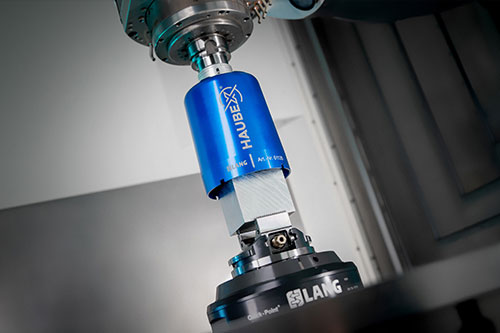

More detailsHAUBEX Automation System

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vise and workpiece blank.

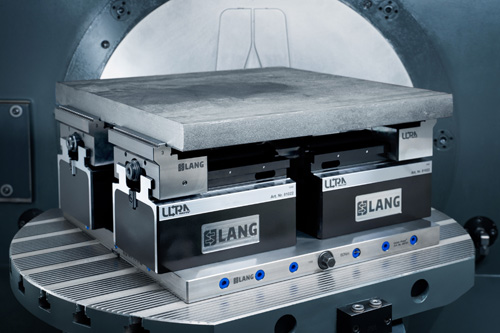

Learn moreMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

More detailsClean•Tec Chip Fan

The chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

More details