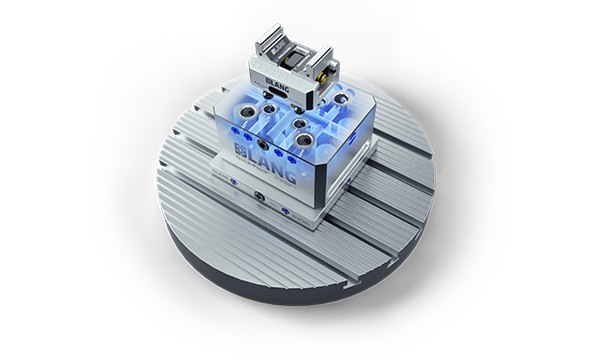

Quick•Point® Zero-Point Clamping System

The enormously adaptable zero-point clamping system for shortest set-up times and highest precision

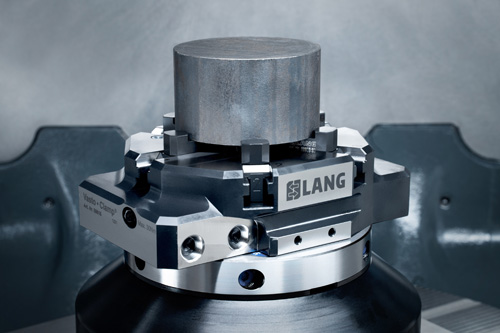

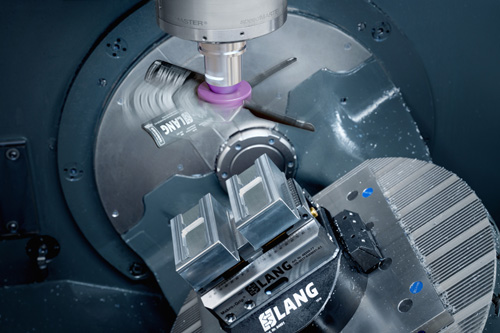

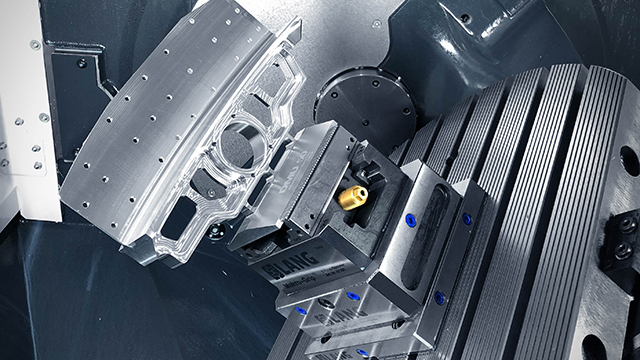

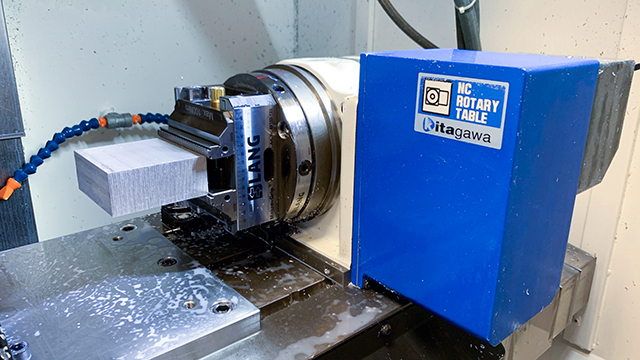

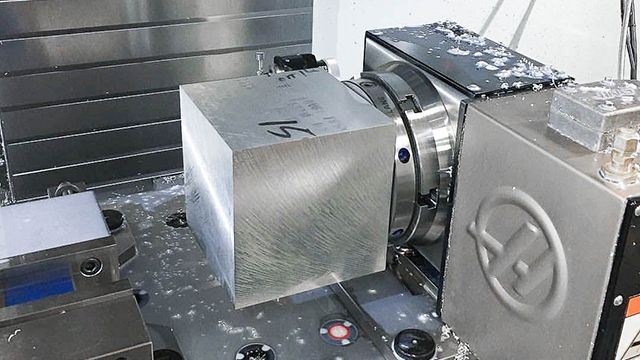

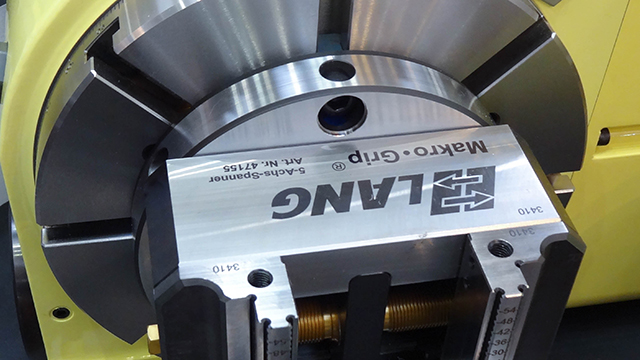

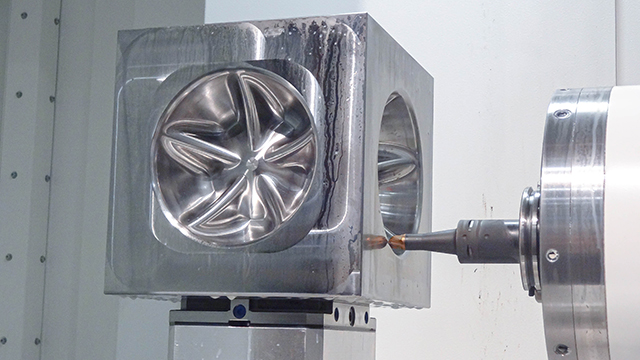

As an interface between machine table and workholding device, Quick•Point® is characterized by an enormous range of variations and provides a solution for nearly any machine tool when it comes to set-up time savings and minimization of downtimes. Round, rectangular or square in shape, for single or multiple clamping, it can be used universally in vertical and horizontal machining centers, on 3- and 5-axis tables and 4th axis rotary or trunnion systems.

With over 50 different zero-point solutions and a wide range of customization options, the LANG zero-point clamping system is extremely flexible. Its user-friendliness and application diversity are unparalleled on the market. Thanks to its modularity, the system can be expanded at any time and guarantees the shortest set-up times with the highest precision.

Even simpler, even stronger

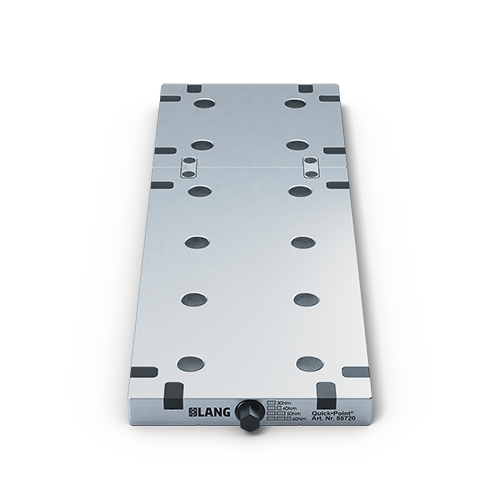

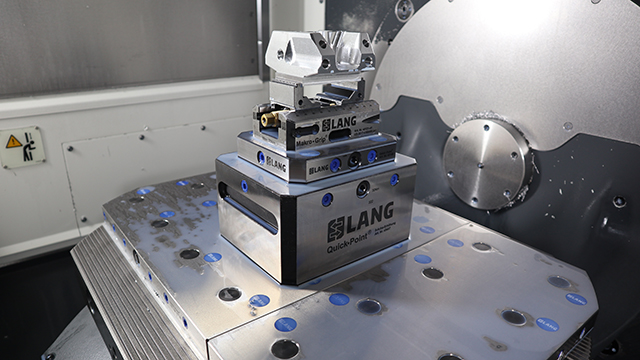

Quick•Point® modular plates

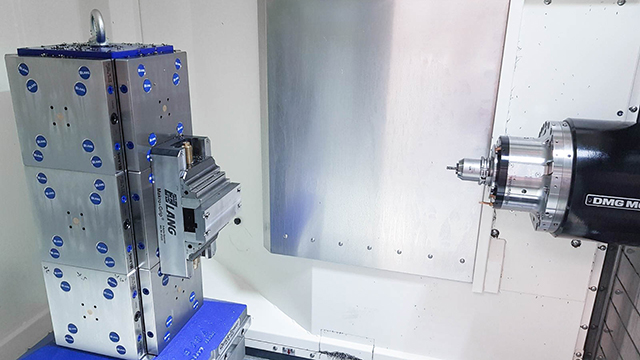

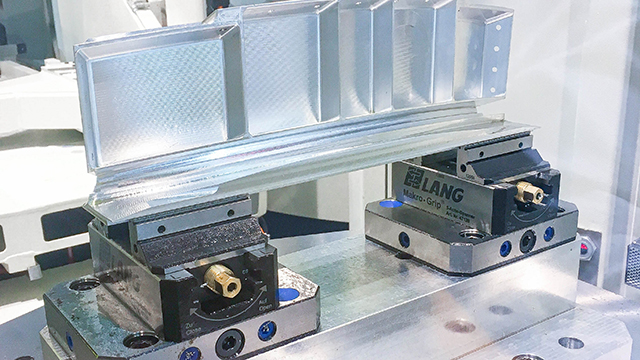

A new type of plate within the Quick•Point® system now makes zero-point clamping even easier. With the expandable modular plates, which can be flexibly adapted to any machine table, users operate up to five clamping units in succession mechanically with just one tightening screw. This is due to a new patented clamping mechanism within the modular plates, which ensures even higher pull-down forces and activates the complete zero-point set-up at the same time.

Quick•Point® modular plates -

The most important info briefly summarized:

- Mechanical clamping of several plates with only one tightening screw

- Single and double plate with 96 mm zero-point grid

- Combinable in y-direction up to 960 mm length (5 clamping units)

- Flexible adaptable to any machine table

- Pull-down forces of up to 8500 N

- No additional alignment of several plates to each other

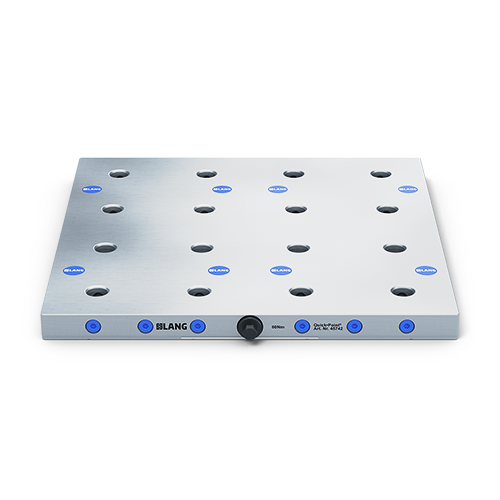

The 2-in-1 solution

Quick•Point® Combo Plates

Greatest possible flexibility. High precision. Short set-up times. Attractive price. Quick•Point® combines all the features that make a zero-point clamping system special. The new Combi series with integrated 52 and 96 mm zero-point grid takes this to the next level. For the user, this means: An even greater flexibility in terms of clamping device selection. All vise sizes can now be clamped in the same platen without having to change over the zero-point system.

View product categoryCheck your set-up time savings now!

Does a Quick•Point® zero-point clamping system pay off for my company? Check out now!

Our Quick•Point® zero-point clamping system saves you {{ setup_time_saved }} hours of set-up time per year!

This corresponds to:

This calculation is only a rough guide to the set-up cost savings. This calculation is based on a factor of 2 (2 minutes) per set-up process with the Quick•Point® zero-point clamping system. The result refers to a 52-week year.

Convinced by this result? Then simply use the contact form to ask for your individual quote.

Product overviewApplications

Modular, flexible and always a good fit

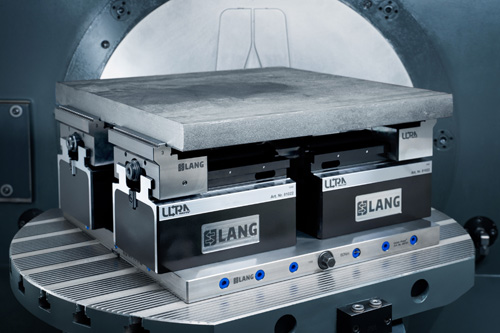

on machine tables

on 4th axis and trunnions

in horizontal machining centers

on pallet changers

Quick•Point® Technology

System height

- With only 27 mm one of the lowest zero-point clamping systems on the market

Zero-point positions

- Highly precise with < 0,005 mm repeat accuracy

Grid size

- 2 different spacings: 52 und 96 mm

Covers

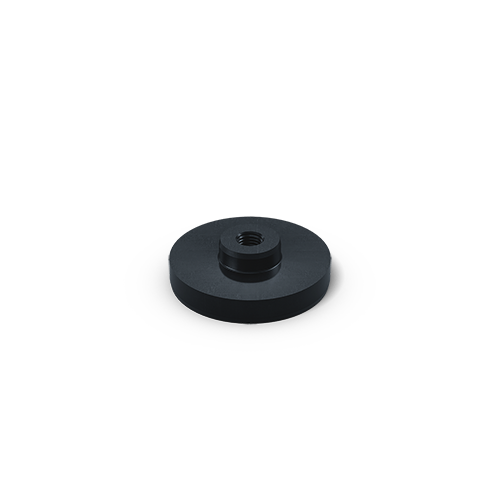

- Cover discs for mounting bores to avoid chip accumulation

Mechanism

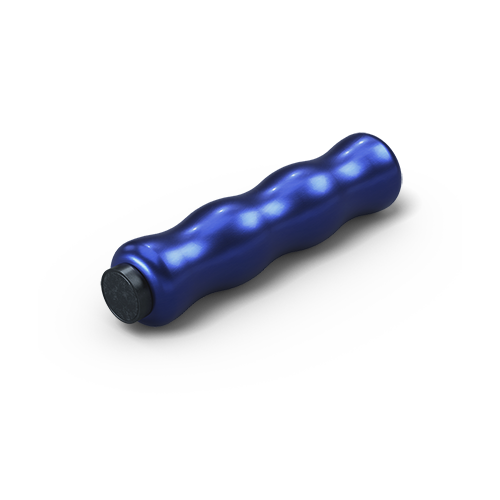

- Robust, mechanical clamping by means of tightening screw or alternatively via Quick-Lock fastener

Material

- Sturdy, solid body made of case-hardened and ground steel

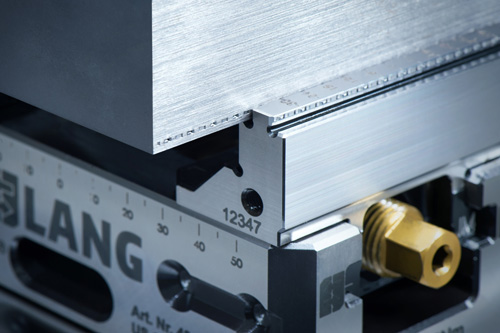

Clamping edge

- As a mounting option for any type of machine table

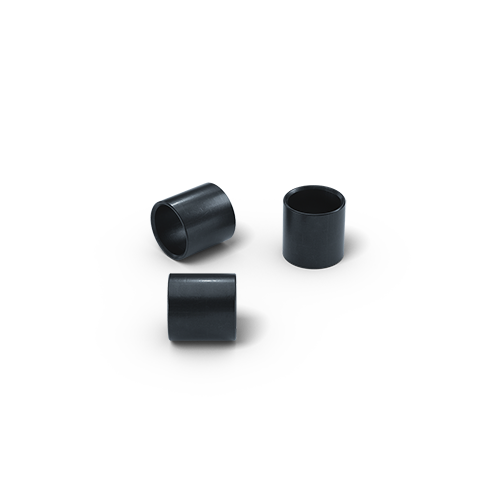

Fitting

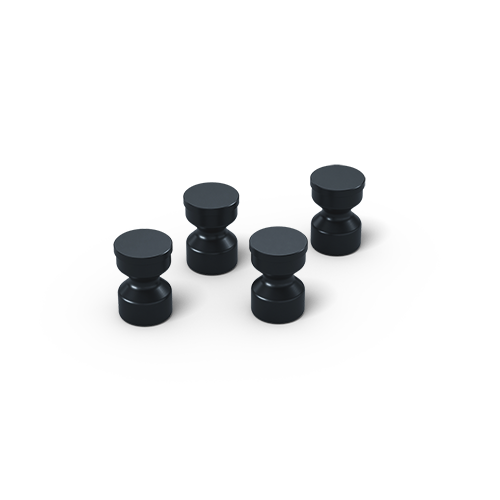

- Ø12F5 fittings for concentric alignment. Matching centering studs are also available.

Coolant drain

- Drain for coolants

Keyways

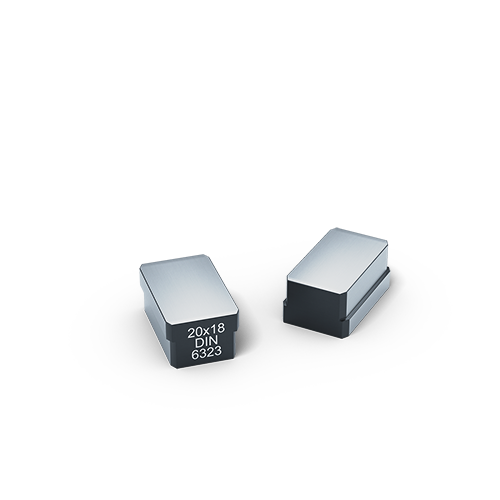

- 20H7 keyways for axial alignment

Functions

Simple, robust and incredibly durable

Mounting on the machine table

Clamping mechanism

Mechanical actuation with tightening screw

Mechanical actuation with the Quick-Lock fastener

Automatic, pneumatic actuation

Benefits

Convinced by the benefits of the Quick•Point® Zero-Point Clamping System?

Then simply use the contact form

to ask for your individual quote or visit our online shop.

Product overview

Products

The two Quick•Point® grid dimensions 52 mm and 96 mm, to which many systems accompanying the market refer today, were established by LANG. The shape, size and application possibilities of the zero-point plates are so varied that almost any requirement on 3- or 5-axis tables or rotary tables can be covered.

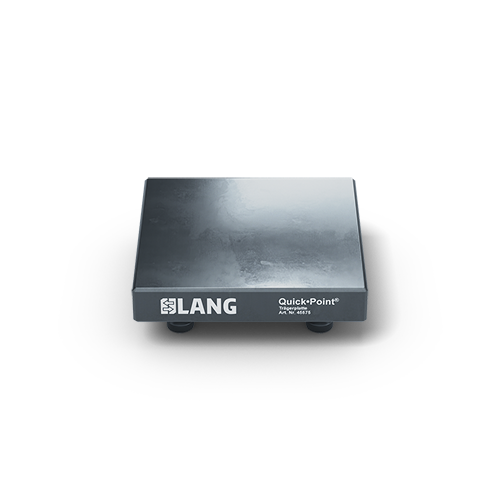

Single plates

Multiple plates

Adaptor plates

Modular plates

Combo Plates

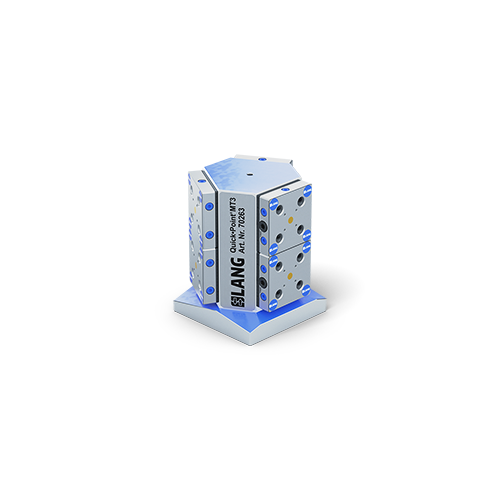

Tombstones

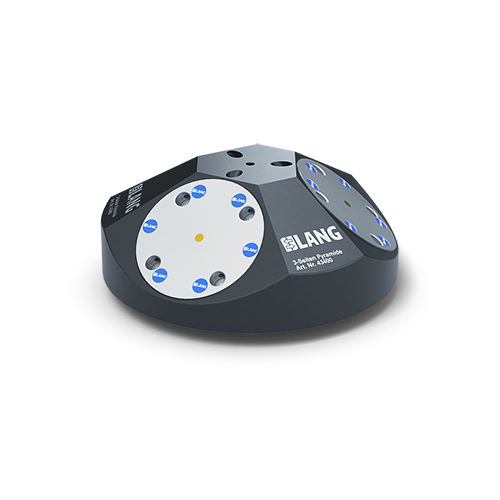

3-face pyramid

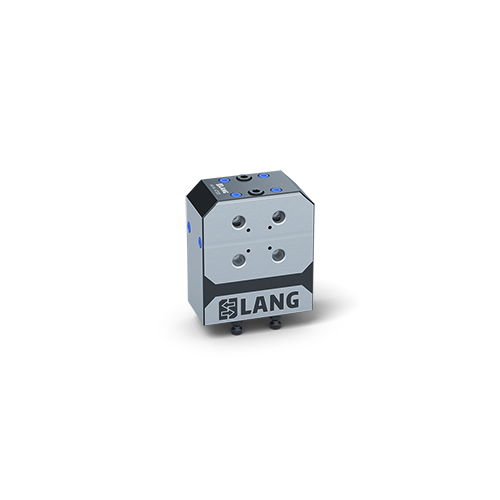

Twin base

Automation zero-point devices

5-Axis risers

Aluminium riser

Support plates

Accessories

Services

You want to individualize and modify your zero-point plates?

Mounting bores

All zero-point plates with prefabricated hole pattern for mounting on the machine table are also available in a version without hole pattern. The case-hardened zero-point plates (57 HRC / 0.7 mm deep) can be drilled individually and provided with the hole pattern matching the t-slot table.

Custom corner radius

Upon request, zero-point plates can be adapted to round tables of the machine tool by milling off corners. This adaptation looks visually clean and in most cases avoids protrusion on the machine table.

Center hole

For some zero-point plates, it is possible to insert a center hole with an individual diameter and tolerance which provides the option for access to rotary joints. Depending on the grid size, the diameter can be up to 38 or 80 mm.

Pneumatic actuation

On request, the zero-point plates are available with customized pneumatic actuation. This solution enables the automated control of the zero-point clamping system via the media interface of the machine tool.

From our blog

You can find more detailed information and application examples in our blog

Success Stories

Start your own success story with the Quick•Point® Zero-Point Clamping System. This is what our customers say:

LANG products caught my eye first and foremost because they are made of iron and not aluminium. Also noticing that they are used in high precision machine shops. I committed to try some of their products out and never looked back. Hands down the best vises and plate fixtures I have used to date.

Chip Ursu, Chips Motorsports LLC, Warren USA

Since we have been using the Quick•Point® system from LANG Technik we have reduced our set-up costs considerably. We even equipped our self-made clamping devices with Quick•Point® clamping studs. Converting to different vises or fixtures now only takes a few minutes. Furthermore, we are pretty much sold on its clamping force and the precision in terms of repeatability

Martin Reschke, EL Bauteile Handelsgesellschaft mbH, 76356 Weingarten, Germany

In order to be able to react quickly to the requirements of a wide range of clamping applications and to keep set-up times as short as possible, we use the LANG zero-point system. Due to the low overall height, the purely mechanical actuation, and the great variety, the zero-point system of LANG has been a real game-changer to us for years. The relatively small stud pitch of 52 and 96 mm, in contrast to mostly 200 mm from other manufacturers, is particularly important to us. As a result, we do not lose any space when clamping multiple parts. We are able to place more vises on the same area and thus process more parts in one run.

Sebastian Thoma, Thoma-Tec, 84155 Bodenkirchen, Germany

I have one Quick•Point® 4-fold Plate on my rotary table and I use this as a base plate to mount everything on top of it. Besides, I have various smaller Quick•Point® plates that I mounted on top of my self-made risers for 5-axis machining. Own fixture and other vises were equipped with LANG pull studs, so I can change and load products in the blink of an eye. The Quick•Point®’s clamping mechanism proves to be absolutely safe. The largest part I have machined on the Quick•Point® plate so far had a total height of 745 mm (incl. riser), just held by 4 (M10!!) LANG pull studs. Anything I machine is based on the 96 mm Quick•Point® distance and I love it!

Kain Borst, Poseidon Propulsion, Barendrecht Netherlands

Increased machining hours? Do not waste any more (set-up) time!

Product overviewLearn more about other solutions by LANG

RoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

More detailsQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

More detailsMakro•Grip® Raw Part Clamping and Stamping Technology

Clamping parts by form-closure – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

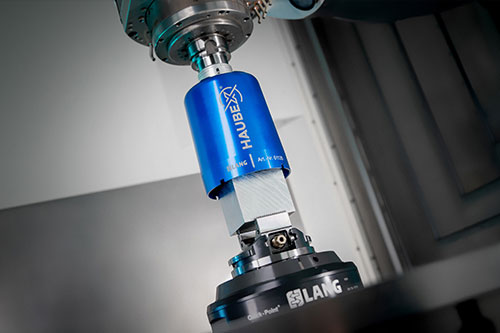

More detailsHAUBEX Automation System

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vise and workpiece blank.

Learn moreMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

More detailsConventional Workholding

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

More detailsClean•Tec Chip Fan

The chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

More details