Zero-point clamping, workholding

and automation – all from one source

- Zero-Point Clamping System Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

- Workholding Clamping parts by form-fit – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

- Automation RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

The 3 main product areas of LANG Technik

Quick•Point® Zero-Point Clamping System

Discover now:

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

Learn more

Quick•Point® Rail Schnellspannsystem

Jetzt entdecken:

Maximale Effizienz bei minimalem Ressourceneinsatz – das revolutionäre Schnellspannsystem für alle Maschinentische und Automationspaletten im Bereich CNC-Fräsen.

Mehr erfahren

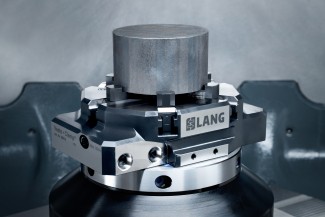

Makro•Grip® Raw Part Clamping and Stamping Technology

Discover now:

Clamping parts by form-fit – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

Learn more

Makro•Grip® Ultra

Discover now:

The modular workholding system Makro•Grip® Ultra is characterised by an enormous application variety and is ideally suited for clamping plates and large parts.

Learn more erfahren

Conventional Workholding

Discover now:

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

Learn more

RoboTrex Automation

Discover now:

RoboTrex covers every need from single part to large-scale production. It is flexible, easy to use and offers best value for money.

Learn more

HAUBEX Automation System

Discover now:

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vice and workpiece blank.

Learn more

Clean•Tec Chip Fan

Discover now:

The Clean•Tec chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

Learn more