Key data at a glance

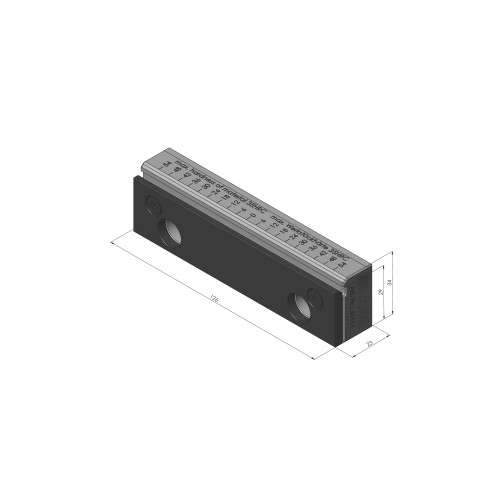

With the stamping jaws mounted on the stamping unit, the workpiece blank is provided with a defined contour under high pressure and held by form-fit in the Makro•Grip® 5-axis vise. Standard stamping jaws are designed for materials up to a maximum of 35 HRC. Parallels on which the blank rests during the stamping process are included in the delivery and pre-mounted. The clamping depth of 3 mm is identical to the clamping depth for the subsequent workpiece clamping.

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover nowServices

We will be happy to advise you individually and adapt your products for the best possible application.

Reconditioning of Stamping Jaws

When the stamping teeth are worn out the jaws can be reconditioned up to 6 times. The origi-nal thickness of a stamping jaw is 18 mm. With every reconditioning process the thickness is reduced by 0.5 mm until it has reached 15 mm (measured at the highest stamping tooth tip). If a stamping tooth is broken off more than 0.5 mm need to be removed and the total amount of reconditioning processes is reduced accordingly.