Key data at a glance

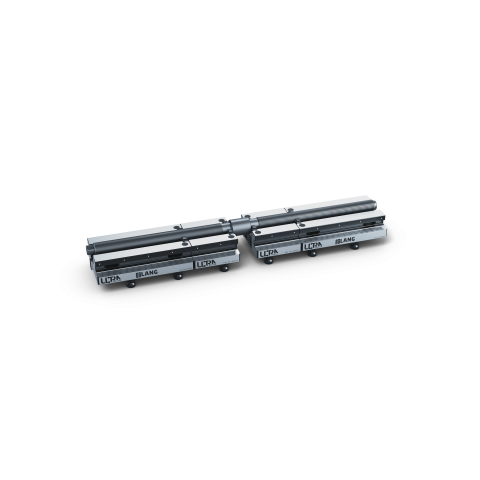

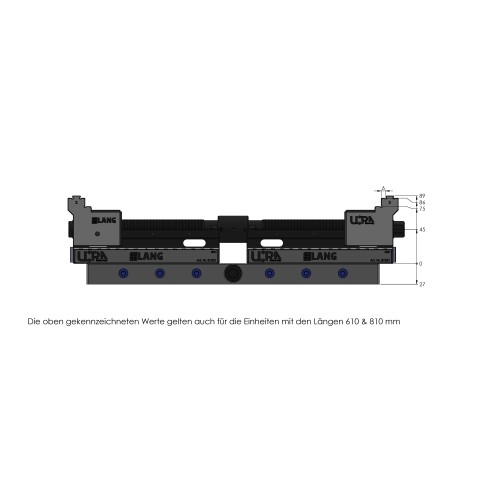

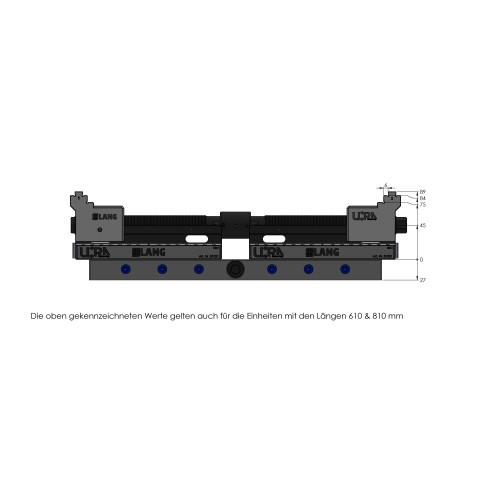

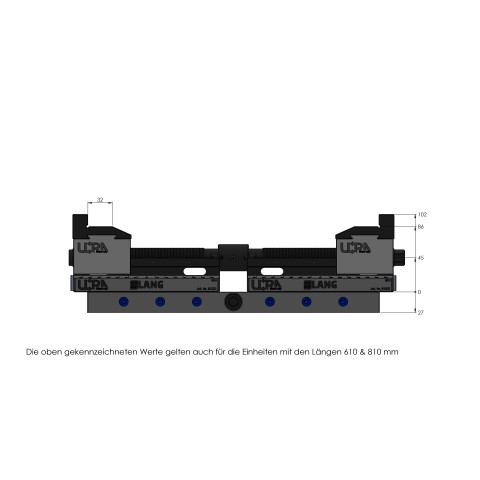

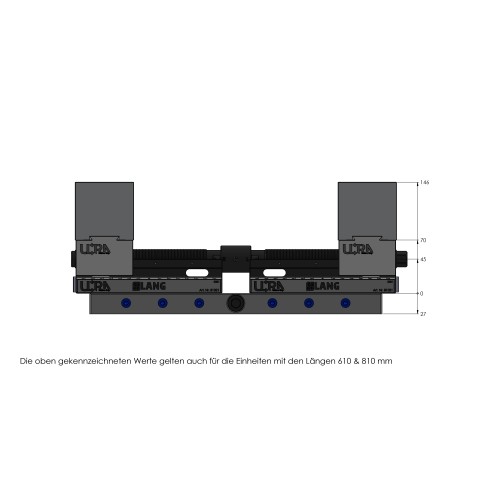

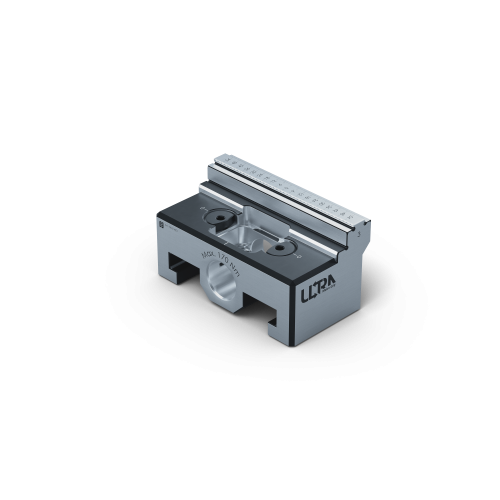

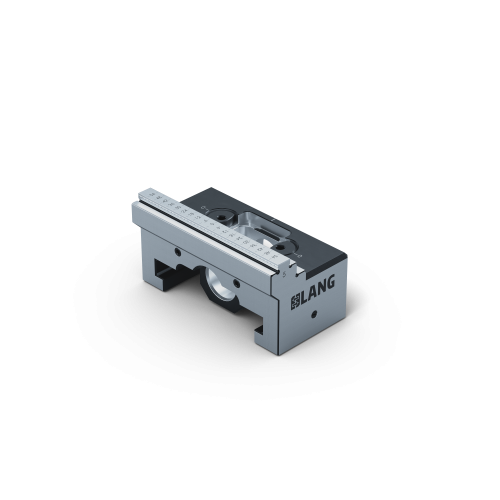

The Makro•Grip® Ultra Base Set “S” with a height of 45 mm consists of two long (192 mm) and two short (96 mm) base bodies each, resulting in a maximum clamping range of 610 mm. The set also includes a spindle unit, centering and connecting plates and accessories. Clamping jaws are available separately. Thanks to its modularity, the base set can be set up, dismantled, extended or shortened within a very short time.

More features:

Single components features:

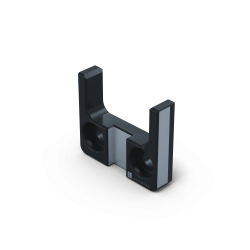

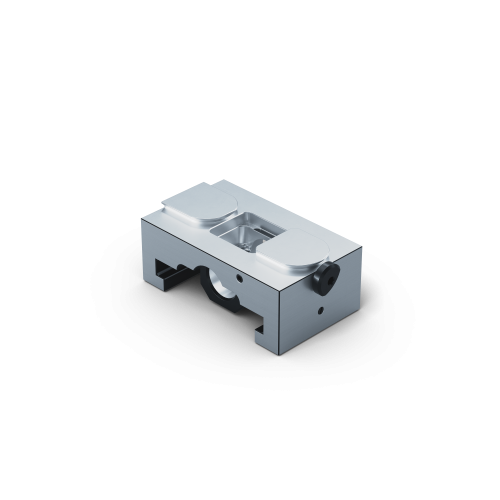

Base Body

Base Body

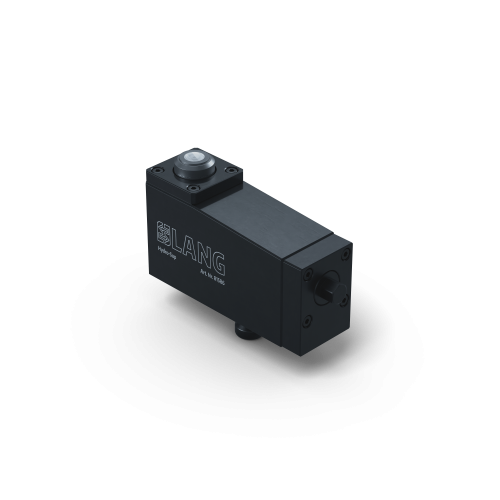

Spindle Unit

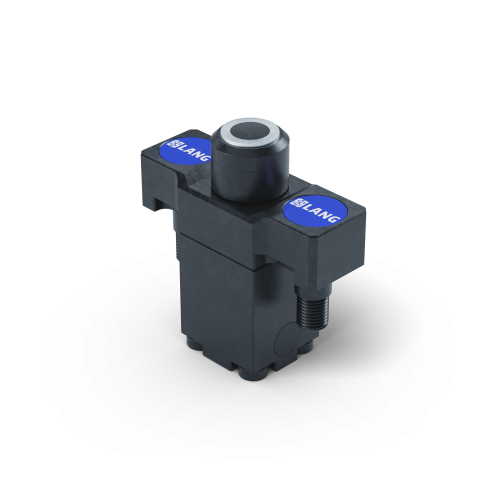

Clamping Studs

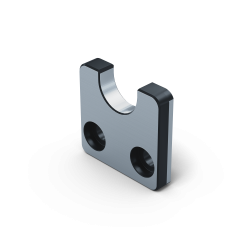

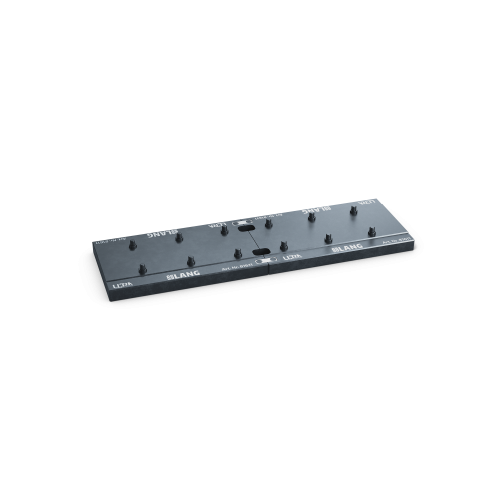

Centering Plate

Connection Plate

Makro•Grip® Ultra

Makro•Grip® Ultra offers countless clamping possibilities and is perfectly fitted for machining applications of flat or large parts and also mould making. Thanks to its expandability and different jaw types, the modular clamping system practically covers any imaginable machining application.

- Modularity Changeover of clamping configuration within seconds through expansion of clamping ranges and exchange of clamping jaws

- Application diversity Equally applicable for single part or multiple clamping, cubic, round our asymmetric workpieces

- Centric clamping of large components Possibility of clamping workpieces of 800 mm or even larger

Learn all about the benefits and functionality of Makro•Grip® Ultra.

Discover now