Key data at a glance

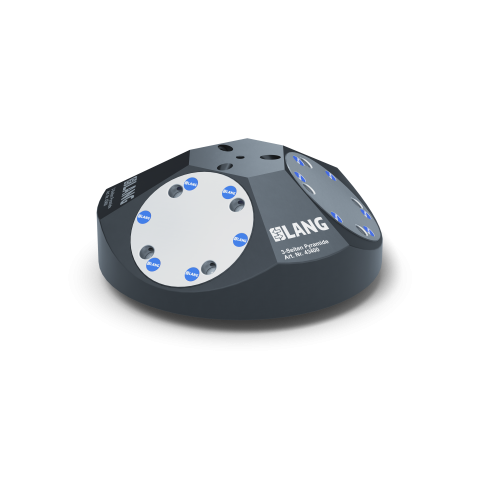

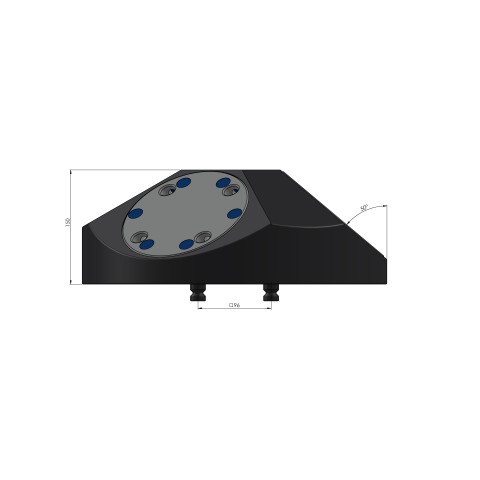

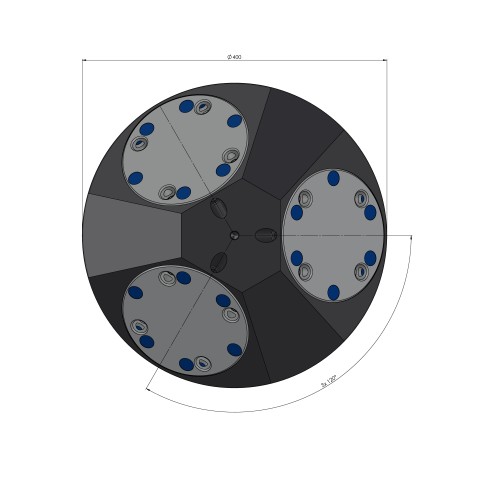

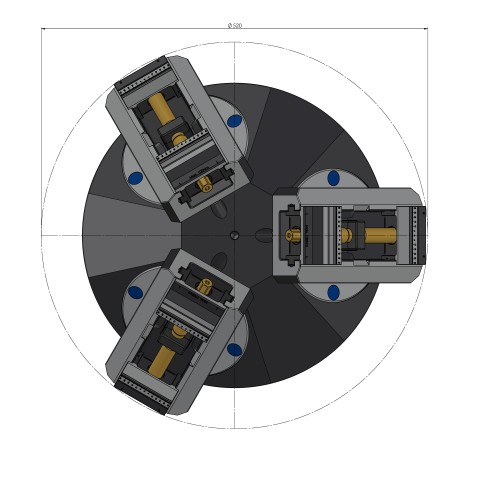

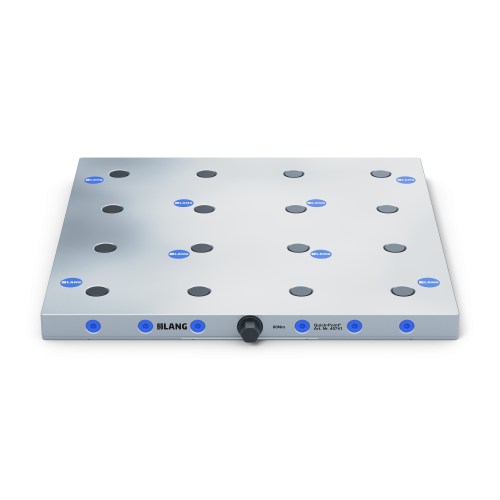

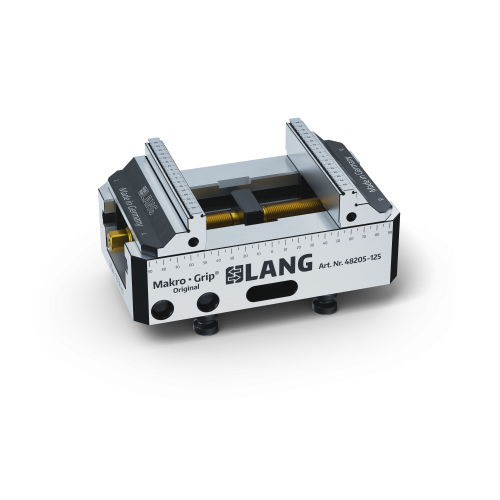

The ideally accessible, high-strength aluminium system body with recessed zero-point plates made of case-hardened steel is particularly suitable for increasing the machine runtimes of 5-axis machining centers. Given that the 3-sided pyramid has an integrated zero-point interface, the operator also benefits from optimized set-up times. Depending on the clamping direction of the system bodies, they can realize a clamping range of max. 205 mm (vertical) or max. 255 mm (horizontal).

More features:

Benefits Quick•Point® Multi-Face Fixtures

- Increase of machining hours Less downtime and tool changes thanks to multiple clamping

- Compactness Also suitable for smaller 5-axis machine tools

- Set-up time savings Fast setup and dismantling in the zero-point system

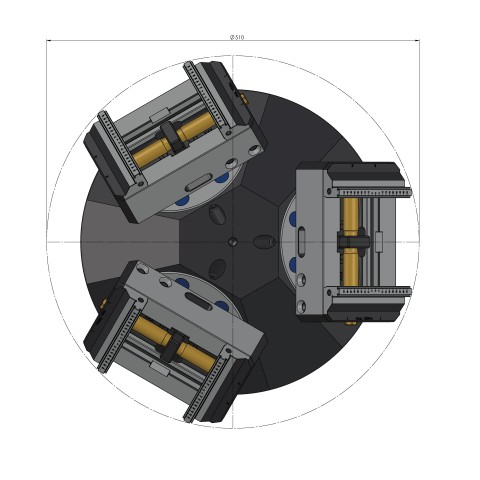

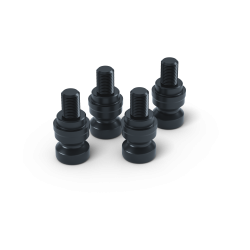

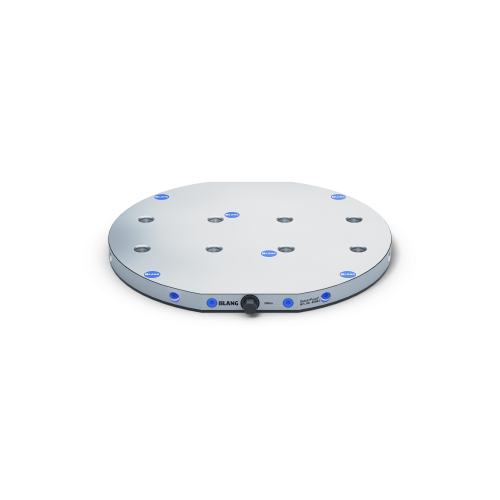

Quick•Point® Zero-Point Clamping System

The Quick•Point® Zero-Point Clamping System is characterized by a particularly wide range of variations and provides a solution for any machine tool. Whether round, rectangular or square in shape, for single or multiple clamping, it can be universally used in vertical and horizontal machining centers, on 3- and 5-axis tables and 4th axis rotary or trunnion systems.

- Flexibility Thanks to the wide range of variations Quick•Point® can be retrofitted to any machine tool.

- Easy operation The simple and robust mechanical principle and the small number of components ensure maximum durability with little maintenance.

- Modularity Whether changing the system size or using additional zero-point components, Quick•Point® can be supplemented and expanded as required.

Learn all about the benefits and functionality of our Quick•Point® zero point clamping system.

Discover now