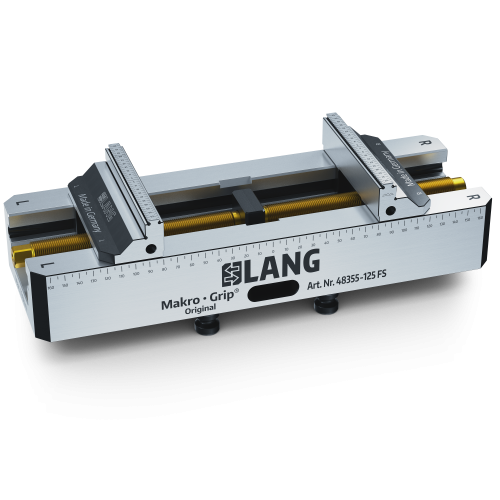

Key data at a glance

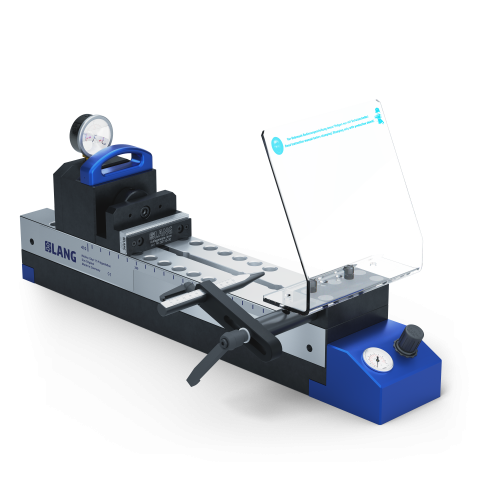

A comprehensive technical revision of the stamping trolleys with t-slot plate and one stamping vise makes the new Makro•Grip® FS version even more flexible. With the new concept, it is now possible to add or expand a second or even third stamping unit without any problems. In addition, the short base body can now also be attached to the grooved plate - more flexibility is hardly possible! The long side of the trolley has a practical drawer for storing tools as well as accessories - everything within easy reach! The pressure control valve is also located at this point, as is the firmly fixed foot pedal that triggers the stamping process entirely without hands. With the High-End version of the stamping jaws (now with four-row full serration), materials up to 45 HRC can be pre-stamped.

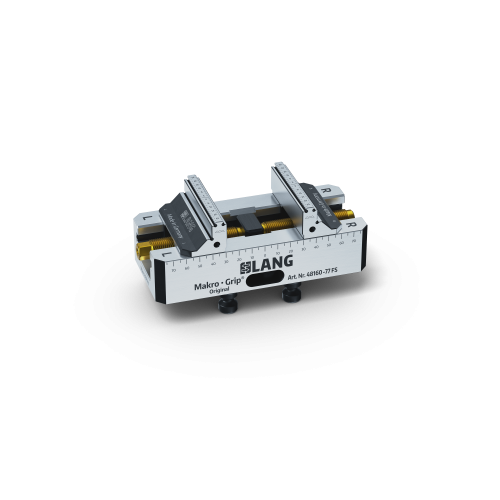

Makro•Grip® FS Stamping Technology and Raw Part Clamping

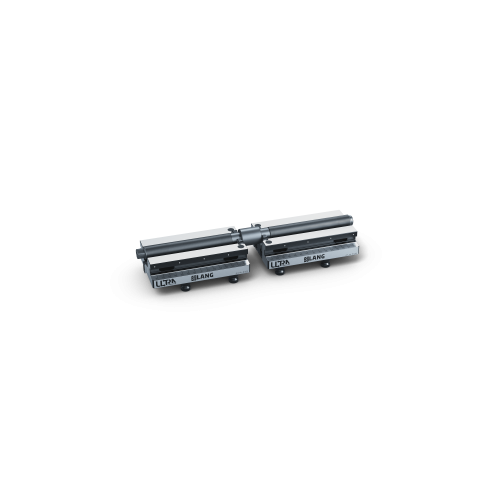

- Holding force Thanks to a new stamping and holding serration, up to 60% higher holding forces can be achieved with Makro•Grip® FS.

- Process reliability Clamping with Makro•Grip® FS offers maximum process reliability and allows even higher cutting rates and faster milling processes.

- Accessibility The compact Makro•Grip® FS self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.