Key data at a glance

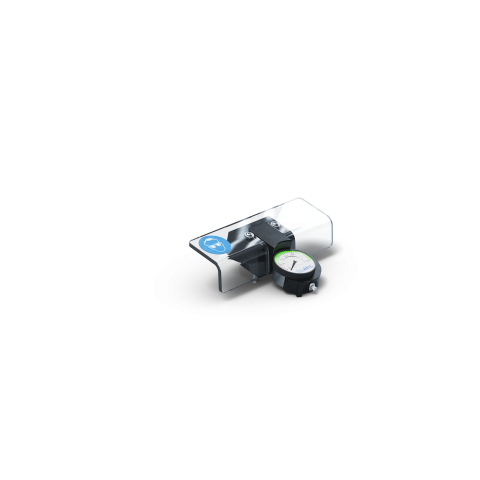

The stamping depth gauge is available as an accessory for each stamping unit of the Makro•Grip® FS series. The use of this measuring device makes it easier and faster to set correct the stamping pressure. A visual inspection of the workpiece blank and possible re-stamping are no longer necessary. Instead, it is enough to simply increase the pressure until the desired stamping depth is reached. The stamping depth can be easily read off the dial gauge. This method makes the entire stamping process more reliable, as it is based less on experience or feeling and more on exact data.

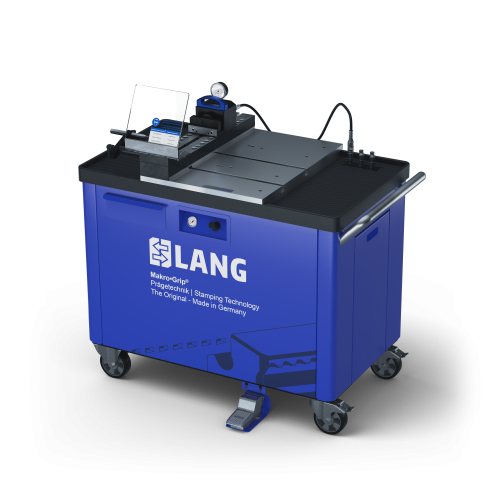

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover now