Key data at a glance

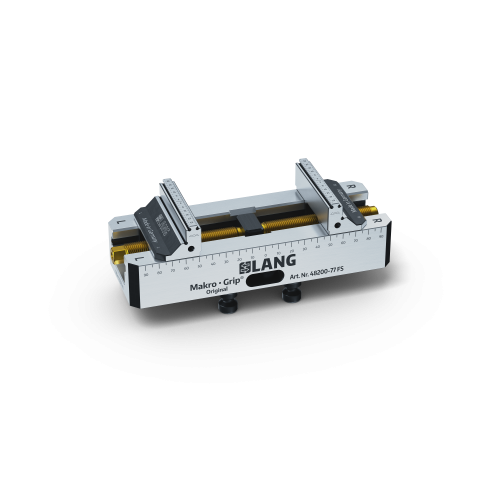

The revised version of the stamping unit as a mobile version on the stamping trolley represents a major redesign of the already familiar model. New types of stamping jaws and features ensure optimized and more ergonomic operation. The stamping trolley itself now has a practical drawer for storing accessories and tools. The pressure setting is conveniently made on the stamping trolley so that it is no longer necessary to reach over the stamping unit. The new version is operated exclusively via a fixed foot pedal, leaving both hands free. In this standard version of the Makro•Grip® FS stamping unit, a stamping base body in the short version up to 260 mm stamping width is fixed on the trolley, but could also accommodate a long base body. The stamping jaws with novel, four-row full serration are suitable for material hardness up to 35 HRC.

Makro•Grip® FS Stamping Technology and Raw Part Clamping

- Holding force Thanks to a new stamping and holding serration, up to 60% higher holding forces can be achieved with Makro•Grip® FS.

- Process reliability Clamping with Makro•Grip® FS offers maximum process reliability and allows even higher cutting rates and faster milling processes.

- Accessibility The compact Makro•Grip® FS self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.