Key data at a glance

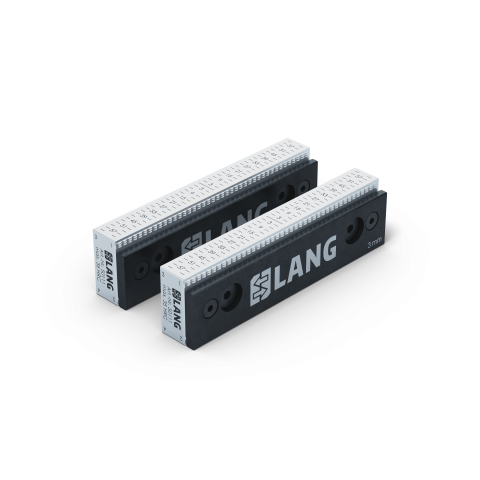

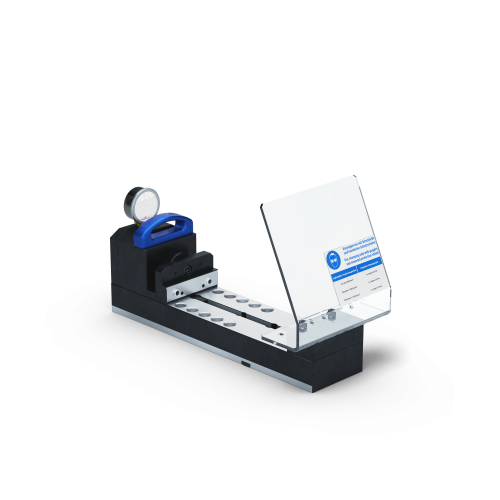

The heart of the new Makro•Grip® stamping units are their stamping jaws. Due to a new, continuous serration, the indentation in the workpiece blank changes during pre-stamping compared to the previous version of the stamping unit. The form fit between this indentation / contour and the continuous serration of the Makro•Grip® 5-Axis Vise provides up to 60% more holding force in the workpiece clamping process. The new stamping jaws are equipped with four rows of stamping teeth (top and bottom on both sides) and can thus be turned three more times after one row of teeth has worn out. This version is designed for pre-stamping materials up to 35 HRC.

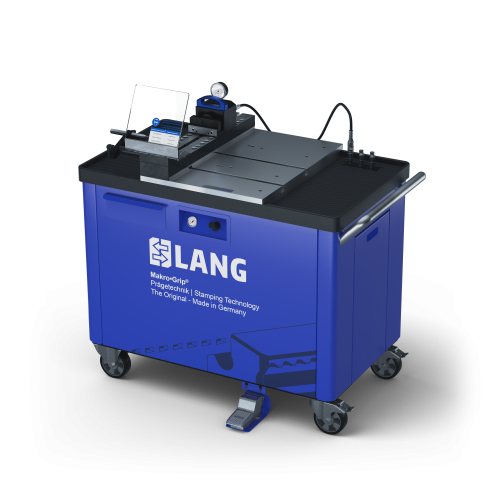

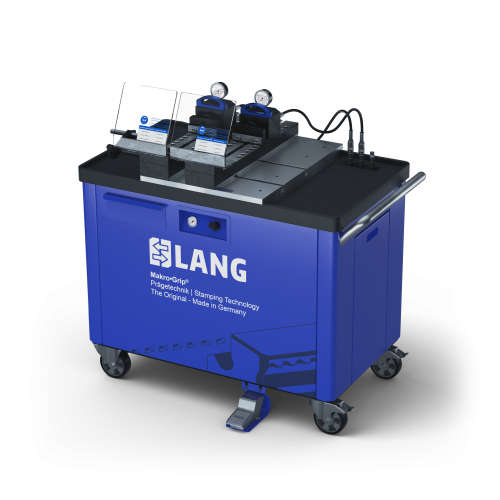

Makro•Grip® FS Stamping Technology and Raw Part Clamping

- Holding force Thanks to a new stamping and holding serration, up to 60% higher holding forces can be achieved with Makro•Grip® FS.

- Process reliability Clamping with Makro•Grip® FS offers maximum process reliability and allows even higher cutting rates and faster milling processes.

- Accessibility The compact Makro•Grip® FS self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.