Key data at a glance

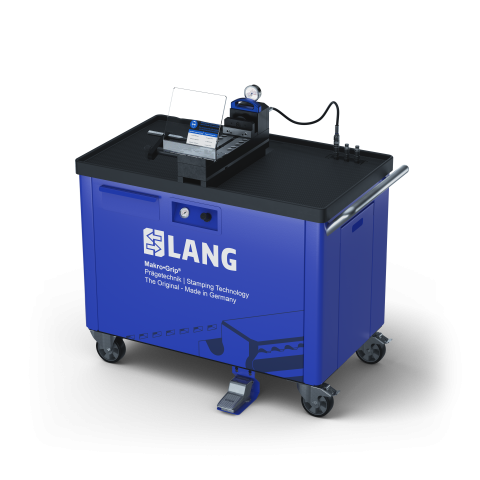

The revised version of the stamping unit as a mobile version on the stamping trolley represents a comprehensive redesign of the already familiar model. New features ensure optimized and more ergonomic operation. The stamping unit itself is supplied without stamping jaws. The stamping trolley now has a practical drawer for storing accessories and tools. The pressure setting is conveniently made on the stamping trolley so that you no longer have to reach over the stamping unit. The new version is operated exclusively via a fixed foot pedal, leaving both hands free. In this standard version of the Makro•Grip® stamping unit, an stamping base body in the short version up to 260 mm stamping width is attached to the trolley, but could also accommodate a long base body.

Makro•Grip® Stamping Technology and Raw Part Clamping

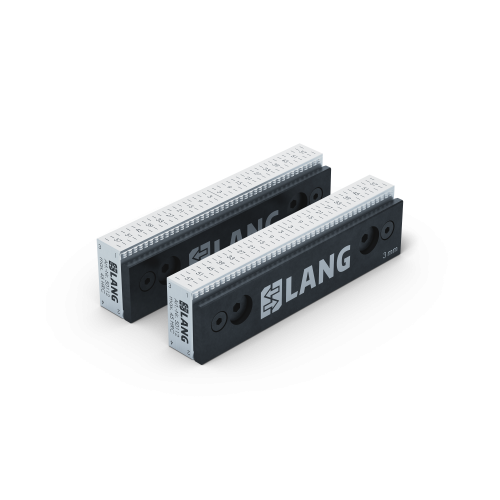

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover now