Key data at a glance

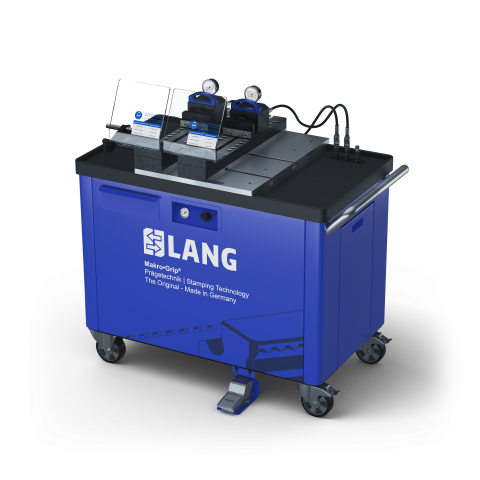

The dual-stamping unit with grooved plate and 2 stamping vises (supplied without stamping jaws) impresses with its optimized operability and even more flexibility in use. The design of the stamping trolley with grooved plate allows a third stamping vise to be added if required. The dual-stamping unit uses the long stamping vise up to an stamping width of 410 mm as standard. However, the short base bodies with a maximum stamping width of 260 mm can also be attached to the grooving plate. More flexibility is hardly possible! The stamping untis are supplied by a pneumatic-hydraulic power multiplier located inside the stamping trolley. Thanks to the new arrangement of elements such as the pressure control valve and the foot pedal, operation is much more convenient.

Makro•Grip® Stamping Technology and Raw Part Clamping

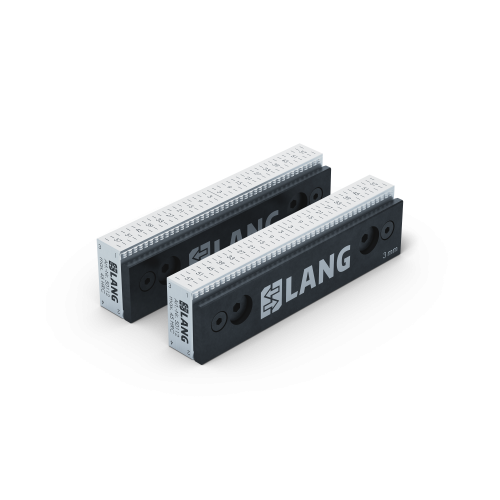

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover now