Key data at a glance

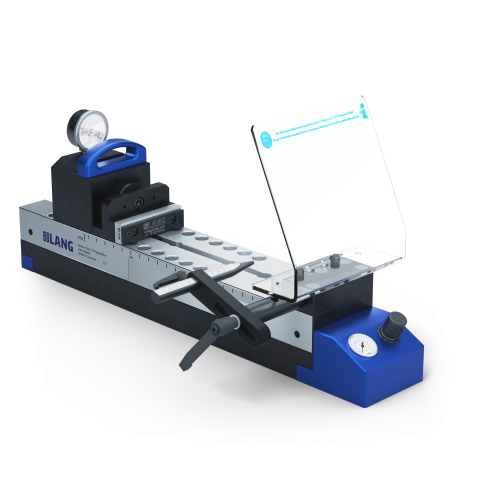

This additional stamping unit is equipped with High-End stamping jaws up to 45 HRC and can pre-stamp workpieces up to 410 mm length. The combination of two stamping vises enables wide workpieces to be pre-stamped so that they can later be clamped using two 5-Axis Vises. This additional stamping vise can be installed either as an extra base on the stamping trolley (with/without t-slot plate) or simply used stationary on a workbench. Suitable mounting material is included in the scope of delivery. No extra pneumatic-hydraulic power multiplier is required for the use of the additional stamping unit.

Makro•Grip® FS Stamping Technology and Raw Part Clamping

- Holding force Thanks to a new stamping and holding serration, up to 60% higher holding forces can be achieved with Makro•Grip® FS.

- Process reliability Clamping with Makro•Grip® FS offers maximum process reliability and allows even higher cutting rates and faster milling processes.

- Accessibility The compact Makro•Grip® FS self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.