CNC vise for 5-sided machining: Why centering vises are the better choice

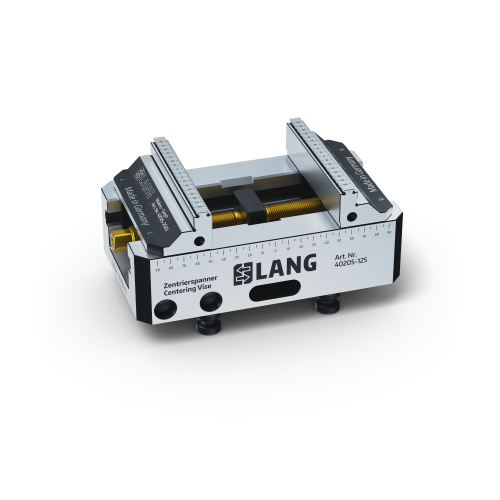

What is a centering vise and how does it work?

A centering vise is a self-centering machine vise in which both clamping jaws move synchronously towards the workpiece. This positions the workpiece exactly in the center of the machine axis. The result:

- Maximum symmetry during machining

- Uniform clamping situation regardless of the workpiece size

- Time savings during retooling

Read the full explanation here: Simply explained: What is a centering vise

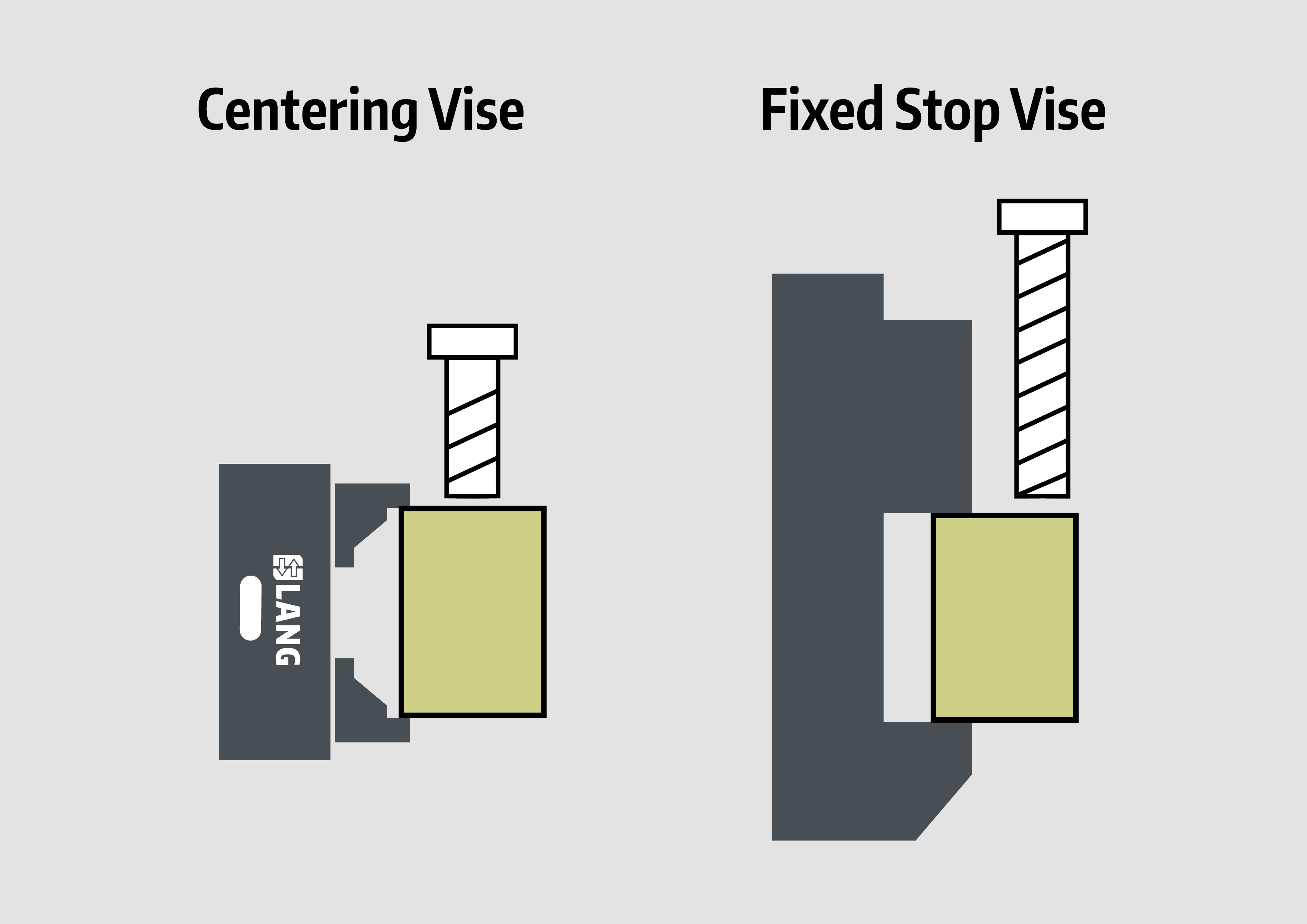

Advantages compared to fixed stop vises

Classic vises with a fixed jaw - so-called fixed stop vises - have their limitations, especially in 5-sided machining. The decisive disadvantage: The workpiece is not automatically centered and access for the tool is often restricted.

Self-centering vises offer clear advantages here:

- Optimal accessibility - Perfect for angled and lateral machining, as is typical on 5-axis machines.

- Shorter clamping times - In combination with the LANG stamping technology and pre-stamped blanks, there is no need for time-consuming alignment through automatic centering or readjustment. Workpieces are clamped in seconds with great repeatability.

- Space saving - Compact design enables the machining of larger workpieces on a small clamping surface.

Better process reliability - Also in conjunction with the stamping technology: The form-fit engagement of the pre-stamped blank means that significantly less clamping pressure is required. This minimizes the risk of distortion, vibrations and component movement.

Thanks to improved accessibility and fewer interfering contours, shorter tools can be used for workpiece clamping with a centering vise. The result: reduced vibrations, longer tool life, and higher cutting values are possible.

The issue of "tilting" of the clamping jaws - and why it is often overestimated

A frequently cited point of criticism of centering vise is the so-called "tilting" of the clamping jaws: When closing, the jaws lift slightly when gripping the workpiece.

In raw part machining, however, this effect is usually insignificant - for two reasons:

- Even lifting of both jaws: As both clamping jaws move synchronously, the workpiece remains centered.

- Sizing of the blank: Slight changes in position in the micrometre range do not play a role here, as material is removed anyway before precision surfaces are created.

With high-quality centering vises such as the Makro•Grip® 5-axis vise, tilting is so low that it has no negative impact on holding force or machining reliability.

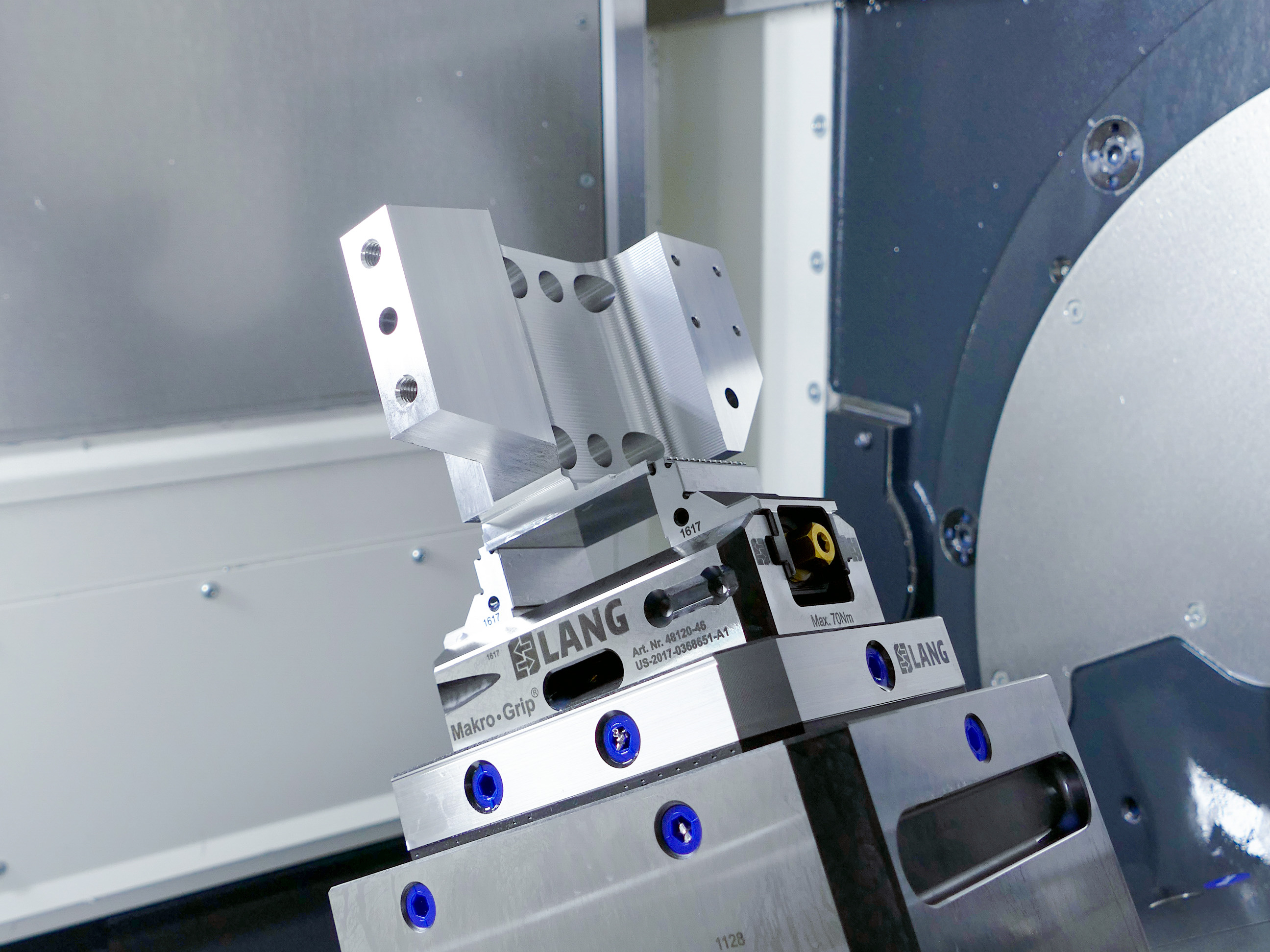

5-sided machining: centering vise as one of the keys to efficiency

Workpieces must be accessible from all sides during 5-sided machining - often in just one clamping operation. Centering vises create the necessary clearance for the tool and enable almost complete machining without reclamping.

The fewer clamping devices in the way, the more efficient and precise the machining process.

Why the Makro•Grip® 5-axis vise from LANG Technik is the first choice

The Makro•Grip® 5-axis vise combines all the advantages of a self-centering vise with the special focus on 5-axis machines - and unfolds its full potential in conjunction with the LANG stamping technology.

Its highlights:

- Maximum accessibility: Compact design for unhindered tool access - even with small clamping heights and complex contours.

- Extremely high holding forces: Thanks to form-fit clamping with a pre-stamped part, the Makro•Grip® holds it absolutely securely even with reduced clamping pressure - ideal for high-strength materials too.

- Shortest clamping times: Pre-stamped blanks can be reproducibly inserted and fixed in seconds without additional alignment or external stops.

- Process reliability: The form-fit reduces clamping pressure, prevents workpiece distortion and ensures stable machining conditions - perfect for precision parts.

Suitable for automation: The combination of fast, reproducible clamping and secure form-fit locking is ideal for unmanned production and automated manufacturing processes.

When pre-stamped workpieces are clamped in a form-fit manner, they hold extremely firmly during CNC machining. This ensures maximum safety.

Conclusion: More precision, more efficiency, more cost-effectiveness

Every advantage counts in 5-sided machining - and even small optimizations in clamping have a direct impact on quality, machining time and costs. Self-centering centring vises clearly beat fixed stop vises in terms of accessibility, precision and flexibility.

The Makro•Grip® 5-axis vise from LANG Technik is therefore the ideal solution:

- For maximum efficiency in one-off and series production

- For maximum precision with complex geometries

- For absolute process reliability - even in unmanned production

If you want to exploit the full potential of your 5-axis machine, this vise is a must.

Questions and answers

Why does LANG Technik not offer vises with a fixed jaw?

For years, we have seen the advantages of 5-axis machining and accordingly align our products with concentric programming. Furthermore, modern probe systems make the reference to a fixed jaw obsolete.

Will a workpiece hold on only 3 mm clamping depth?

Absolutely, yes. The clamping depth of 3 mm is sufficient to securely fix the workpiece on the support surface of the clamping jaw. At the same time, the low clamping edge requirements allow for perfect accessibility from all sides. The machinist can save material and also benefits from a smaller chip removal volume for second operations.

Are the centering vises from LANG robust?

With its case-hardened base body and clamping jaws milled from solid material, the LANG vise can withstand even the greatest cutting forces. In addition, the vices are low-maintenance and low-wear, so that a long service life can be guaranteed.

For more questions and answers on this topic, see the following page:

FAQ