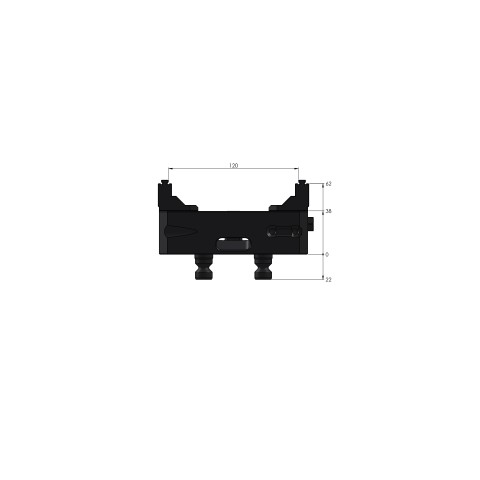

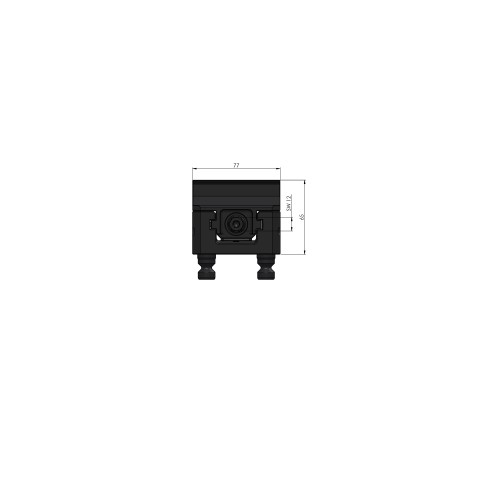

Makro•Grip® 77, Night King

jaw width 77 mm, clamping range 0 - 120 mm

Item No. 68120-77

The Night King is also available with continuous Makro•Grip® FS full serration (item no. 68120-77 FS).

Mehr dazu

The Night King is also available with continuous Makro•Grip® FS full serration (item no. 68120-77 FS).

Mehr dazuKey data at a glance

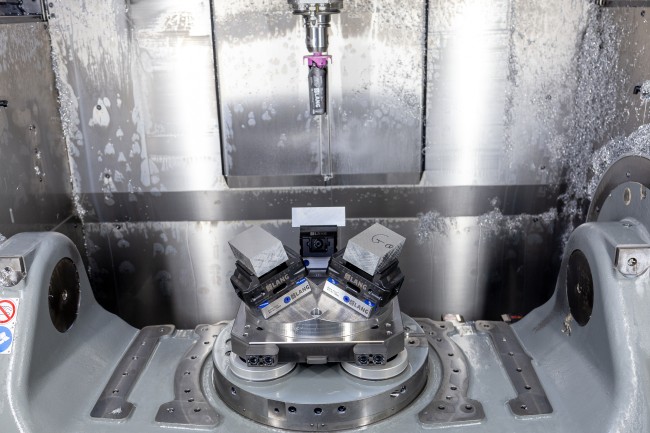

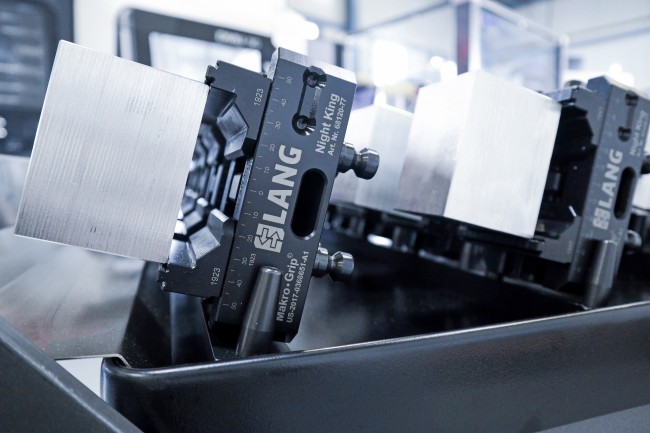

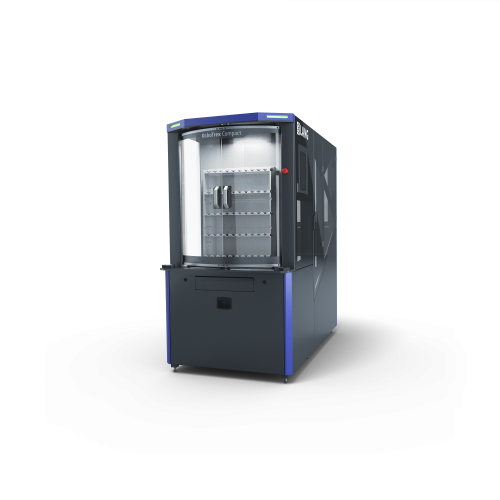

The Makro•Grip® Night King is a pure 5-axis vise that is reduced to the essential requirements in 5-sided machining: Holding power and accessibility. The form-fit clamping principle guarantees maximum process reliability, which plays a decisive role in automated production. The purist design is reflected, in particular, in its acquisition costs, which result in significant cost savings for automation operations with a larger number of vises.

More features:

Single components features:

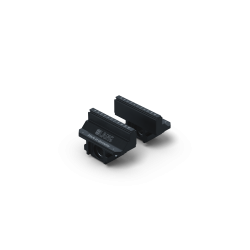

Clamping Studs

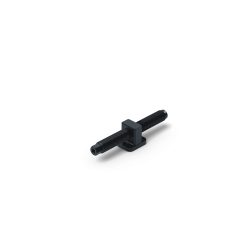

Spindle + Center Piece

Spare Jaws

Can be used in the RoboTrex and RoboTrex Compact automation system.

Packaging unit = 5 pieces

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover now