Key data at a glance

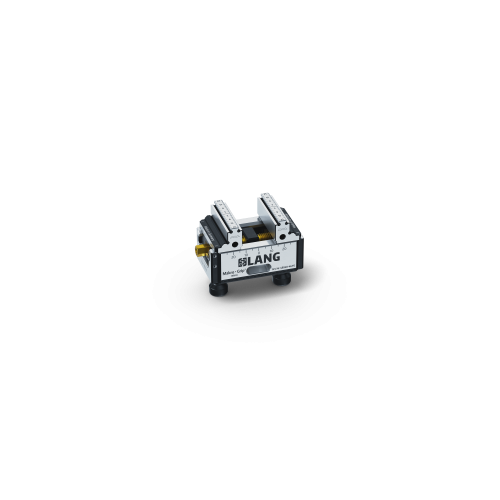

The redesigned stamping unit has been extensively revised and optimized, making it stand out clearly from its familiar predecessor. Numerous changes and improvements have been made to make the stamping process even more pleasant. For example, the one-handed adjustment of the stamping width and the front-mounted pressure control valve ensure even more convenient handling. At the heart of this new development are its revised High-End stamping jaws with quadruple serration in a modified design - specially designed for materials up to 45 HRC material hardness. With an extended component length of 260 mm, the Makro•Grip® FS variant also offers a wider clamping range compared to the old version - another plus point in terms of performance.

Makro•Grip® FS Stamping Technology and Raw Part Clamping

- Holding force Thanks to a new stamping and holding serration, up to 60% higher holding forces can be achieved with Makro•Grip® FS.

- Process reliability Clamping with Makro•Grip® FS offers maximum process reliability and allows even higher cutting rates and faster milling processes.

- Accessibility The compact Makro•Grip® FS self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.