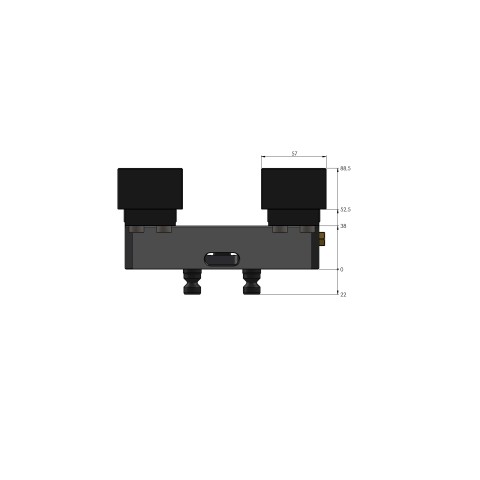

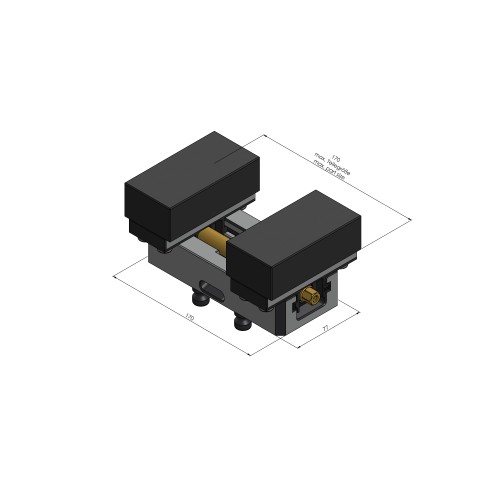

Profilo 77, Profile Clamping Vise

jaw width 112 mm, max. clamping range 165 mm

Item No. 49080-77

Attention: Item no longer available! Please order the base body 40160-77 and the clamping jaws 49077 separately instead.

Learn more

Attention: Item no longer available! Please order the base body 40160-77 and the clamping jaws 49077 separately instead.

Learn moreKey data at a glance

The Profilo vise with its separately available top jaws is a flexible clamping solution for profile and pre-machined parts. The soft, individually machinable top jaws of the Profilo, which are positioned on the base jaws via feather keys and mounted from below with four screws each, are available in steel and aluminium, but can also be manufactured in-house.

More features:

Single components features:

Base Jaws

Jaw length: 46 mm (1.81")

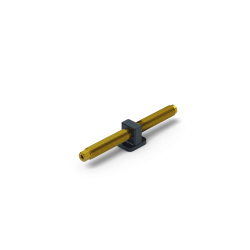

Spindle + Center Piece

Clamping Studs

Benefits Profilo

- Flexibility Top jaws can be manufactured by customers themselves

- Versatility Adaptation of own fixtures to the base jaws possible

- Sturdiness Robust interface between base and top jaw with mounting screws

Conventional Workholding

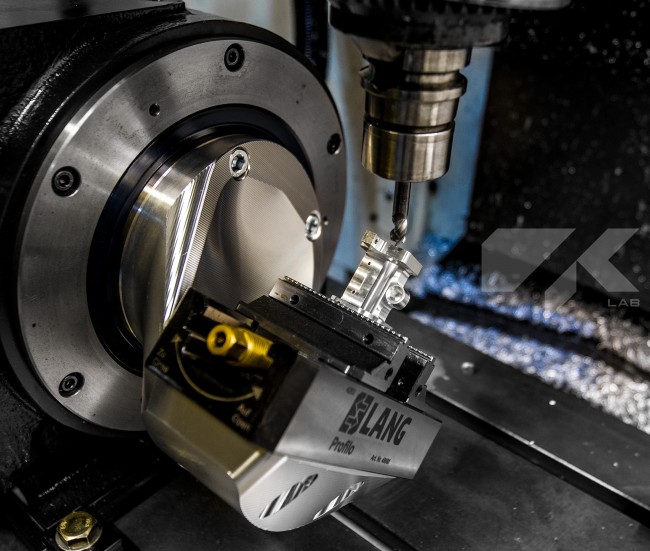

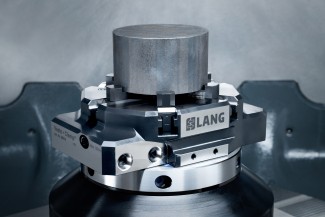

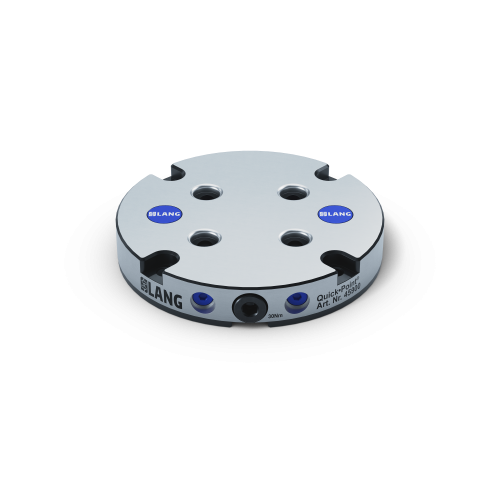

„Conventional Workholding“ offers a multitude of options for clamping round or pre-machined parts. To solve the respective clamping task, the operator can choose between a 6-jaw chuck, two collet chucks and three different types of self-centering vises, whose jaw types are perfectly suited for challenging 2nd operations.

Learn all about the benefits and functionality of Conventional Workholding.

Discover nowApplication pictures

Services

We will be happy to advise you individually and adapt your products for the best possible application.