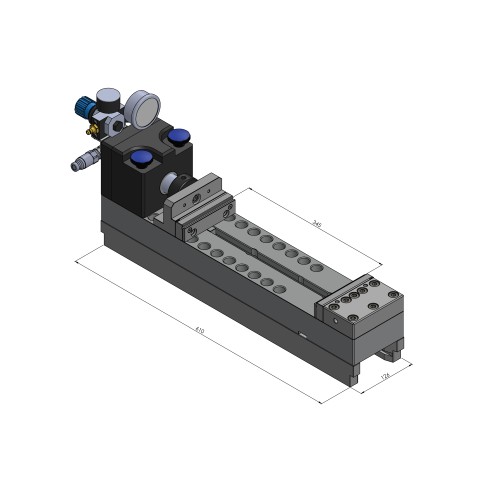

Makro•Grip®, Stamping Unit

Extended, with standard stamping jaws

Item No. 41350

This version of the stamping unit is supplied with a conversion set (item no. 51260-20) consisting of a fixed and movable carrier jaw and our new Makro•Grip® FS stamping jaws (item no. 50111). For everyday use, you do not need to pay any further attention and can pre-stamp your blanks as usual.

This version of the stamping unit is supplied with a conversion set (item no. 51260-20) consisting of a fixed and movable carrier jaw and our new Makro•Grip® FS stamping jaws (item no. 50111). For everyday use, you do not need to pay any further attention and can pre-stamp your blanks as usual.

Key data at a glance

The extended stamping unit for the workbench is equipped with standard stamping jaws for materials up to 35 HRC. In this version, workpiece blanks up to 355 mm clamping length can be stamped. Quick adjustment of the clamping length is possible as soon as the two locking pins are removed from the system body. Fine adjustment to the corresponding workpiece width is made via a spindle. An adjusting wheel on the hydraulic housing of the stamping unit trolley is used to set the stamping pressure continuously up to a maximum of 360 bar. The stamping process is triggered by a pneumatic pedal that can be operated by hand or foot. The scope of delivery includes a protective shield and a scaled end stop for the central, repeatable insertion of the blanks.

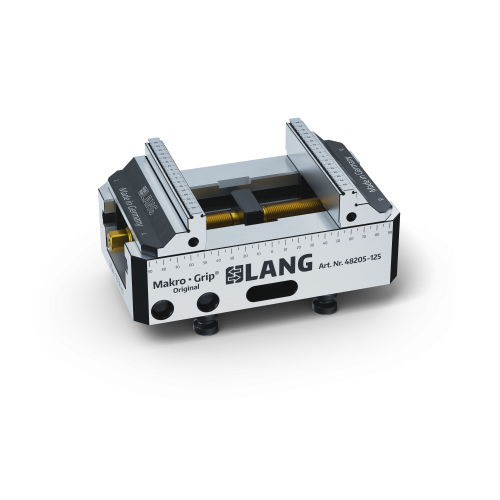

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover now