Increased productivity in manufacturing through setup time optimization

The reduction of setup times is crucial

As a user of LANG Technik products, you will quickly notice that the topic of setup time optimization is particularly important here. After all, reducing unproductive downtime during the setup process is a decisive factor for productivity in machining production. That's why we work every day to optimize processes and design our products to make your work as easy as possible.

We rely on a variety of approaches to reduce set-up times in our production and that of our customers. For example, we offer modular clamping systems and devices to reduce tool changes, which saves you time and effort. In addition, in the age of Industry 4.0, the automation of setup processes is playing an increasingly important role for us.

We would like to support you in making your manufacturing processes even more efficient and thus achieving greater productivity. Because you can only run your company successfully in the long term if you save time and costs - and that's what matters to us at LANG Technik.

Setup time optimization as the common thread

In basically every product group, you will find starting points for setup time optimization with us:

- RoboTrex: Re-equipping of the automation system without downtimes. External preloading of the automation trolleys with blanks enables changeovers within a few moments. Click here to read the blog post

- Makro•Grip® Ultra: Uncomplicated and quick assembly of the workholding system in different clamping ranges and system heights.

- Avanti: Versatile clamping device with quick jaw change system. Change of top jaws for different applications in seconds.

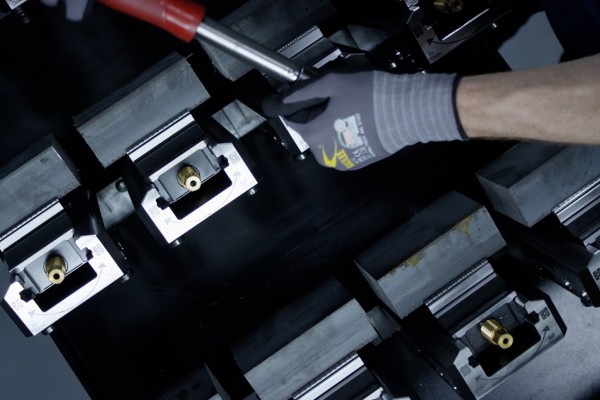

- Quick•Point®: Modular, universally applicable zero point clamping system with highest precision and repeatability.

- Makro•Grip®: Workpiece blank clamping with form-fit clamping principle. Defined, repeatable positioning of the workpieces in the vise's serration for maximum safety and easy handling.

In our blog, we'll be taking up all of these points in the coming weeks and months and shedding more light on them. We'll explain how each of these product solutions will help you speed up, simplify and, quite fundamentally, make your manufacturing processes even more efficient.