Milling of round and

pre-machined workpieces

Chucks and vises with top jaws

Contour clamping vises and chucks are particularly appreciated by our customers as a workholding solution for second operations and the 6th side of workpieces: And even if you are looking for clamping technology for round raw parts, you are sure to find what you are looking for at LANG Technik:

Workholding systems for round or geometrically irregular parts

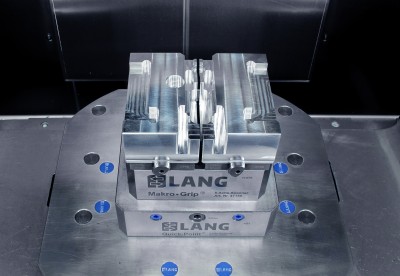

Makro•Grip® 5-Axis Vise

with contour jaws

Makro•Grip® 5-Axis Vise

with Makro•4Grip clamping jaws

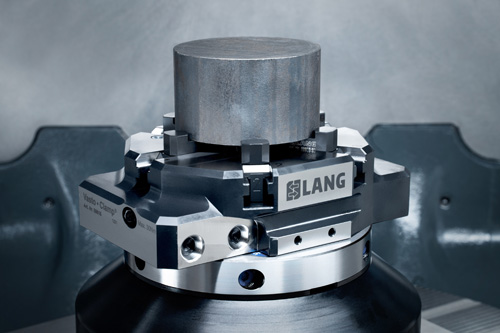

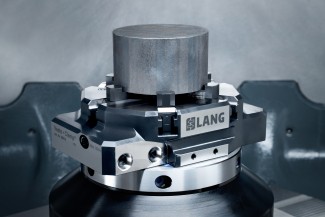

Vasto•Clamp 6-jaw chuck

with top jaws

Preci•Point collet chuck

for ER 32 and ER 50 collets

Getting a grip on all part shapes with our chucks & contour clamping vises

You know it yourself: Not all parts can be held by a 5-Axis Vise with serrated clamping jaws - a good portfolio therefore always includes various chucks and contour clamping vises with which you can efficiently clamp round and pre-machined parts. For this very reason, we at LANG Technik have a suitable clamping device for all component shapes. Whether cubic, round or geometrically irregular workpieces - with us you will find everything you need to get through everyday production safely and confidently.

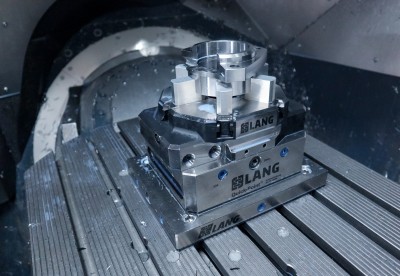

How do we do that? Quite simply: Our chucks / jaw chucks / vises are flexible and easy to handle. This makes their use time-saving and your production more efficient. In addition, all systems can be set up precisely and quickly in the Quick•Point® zero point clamping system, making them the optimal tool in all CNC milling machines.

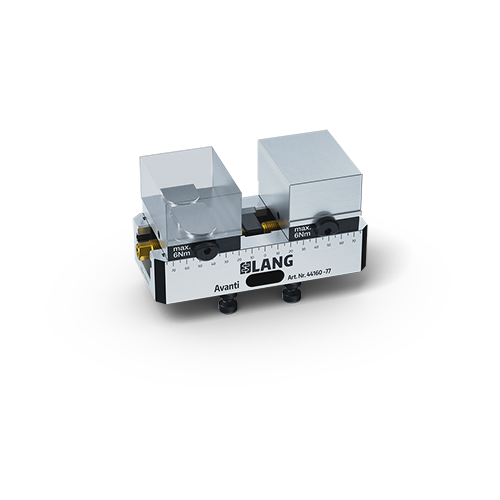

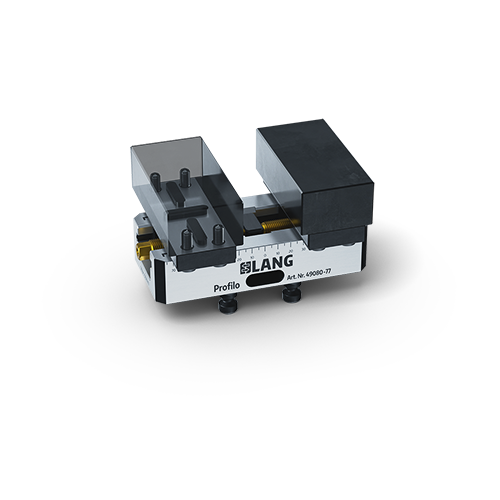

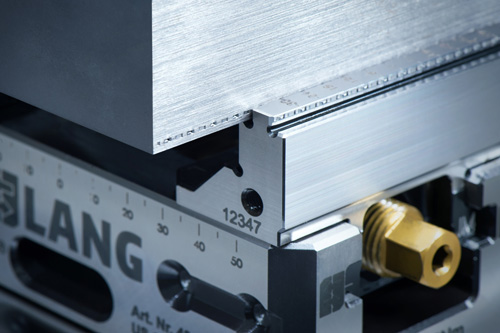

The clamping systems Avanti and Profilo help you with contour clamping. With these two different 5-axis centering vises for contour clamping, users can in principle clamp any component shape - whether round, rectangular or geometrically unshaped. Anything is possible! To ensure that this is done smoothly and with high quality, both systems use exchangeable top jaws with which you clamp the workpieces. The clamping systems differ in the way they are mounted on the base jaws of the 5-axis workholding devices. The Avanti quick jaw exchange system ensures that jaws can be changed in seconds. This makes it a favorite with anyone who is faced with alternating tasks and a high variety of parts in production. Profilo convinces with the possibility to fix also own clamping fixtures and self-made clamping jaws.

Besides these two vises with top jaws, there is another type of contour jaws in our product line. The special feature: the magnetic attachment of the contour jaws. These are simply attached to the clamping jaws of the 5-Axis Vise and kept in position by snapping into the serration.

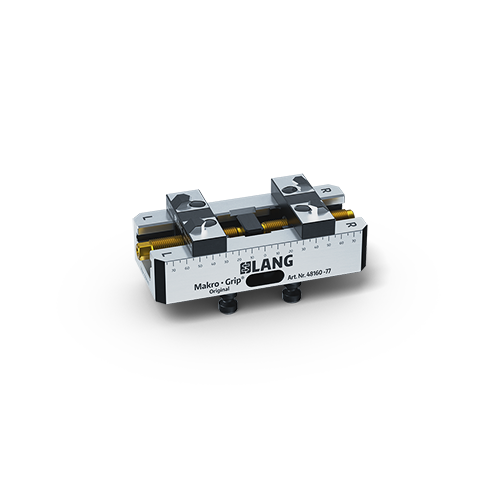

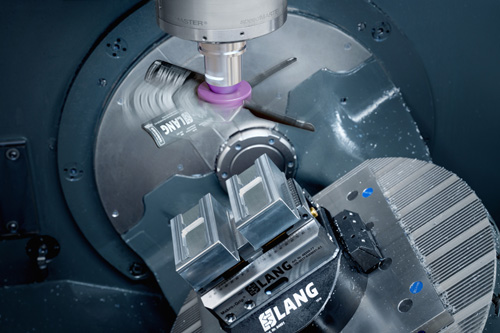

In addition, we naturally also have the right solution for milling round components and support you with three further and different clamping solutions: With Makro•4Grip you realize pre-stamping and form-fit clamping for round blanks. To make this a success, 5-Axis Vises and the stamping unit can be retrofitted cost-effectively and easily. The versatile 6-jaw chuck - which can also be used as a chuck with three jaws - is a true all-rounder. It supports you with inner and outer diameter clamping possibilities and can be used with either hard gripping jaws or soft top jaws. Another plus: the jaw chuck is prepared for automated manufacturing with RoboTrex. It is the innovative mechanism that makes this mechanical 6-jaw chuck a powerful clamping system where you can implement jaw changes without tools.

The Preci•Point collet chuck uses commercially available collets of type ER 32 and ER 50. Especially smaller workpiece diameters of Ø 3 - 34 mm can be clamped efficiently.

6 good reasons for clamping systems from LANG Technik

Do you have a specific application?

Let us talk about it.

Zero point clamping, workholding and automation from LANG Technik

Quick•Point® Zero-Point Clamping System

Flexible, precise and extremely durable – with the modular Quick•Point® system set-up times are reduced to a minimum.

More detailsMakro•Grip® Raw Part Clamping and Stamping Technology

Clamping parts by form-closure – For years the Makro•Grip® technology has been the benchmark in the 5-axis machining of raw material.

More detailsQuick•Point® Rail quick clamping system

Maximum efficiency with minimum use of resources - the revolutionary quick-clamping system for all machine tables and automation pallets in the CNC milling sector.

More detailsConventional Workholding

Conventional Workholding offers flexible and versatile solutions for clamping round or pre-machined components and contours.

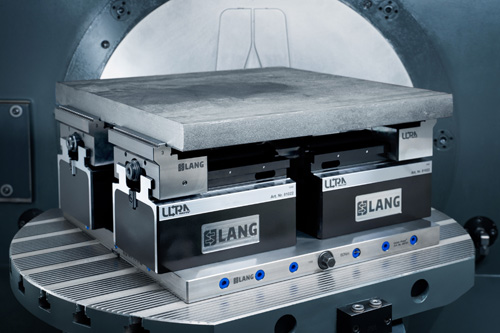

More detailsMakro•Grip® Ultra

The modular workholding system is characterized by an enormous application variety and is ideally suited for clamping plates and large parts.

More detailsRoboTrex Automation

RoboTrex covers every need from single part or large-scale production. It is flexible, easy to use and offers best value for money.

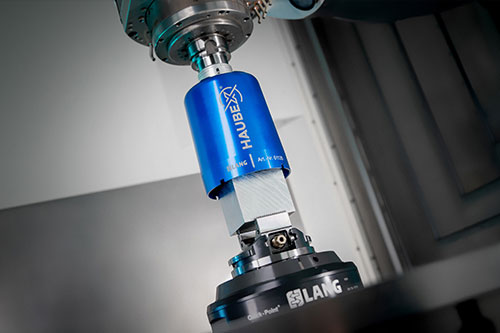

More detailsHAUBEX Automation System

HAUBEX enables the automatic exchange of the workholding device from the tool magazine with a hood as a carrier system for the vise and workpiece blank.

Learn moreClean•Tec Chip Fan

The chip fan automatically removes chips and coolant from machine tables, fixtures and workpieces after the machining process.

More details