Key data at a glance

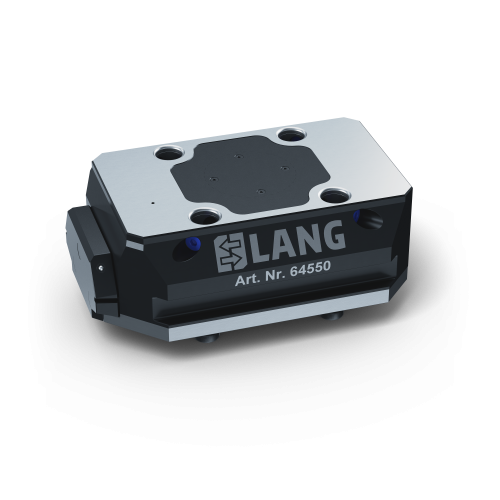

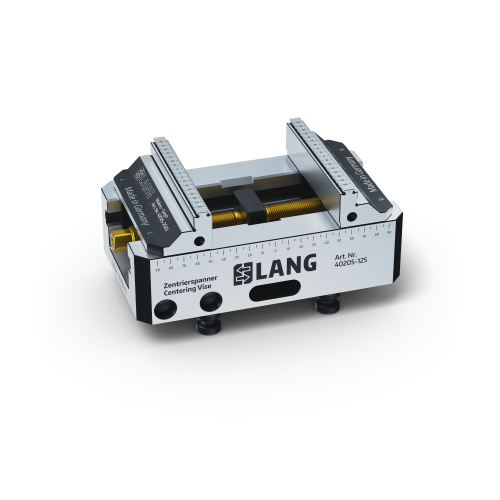

This version of the automation gripper is used in the RoboTrex 96 automation system. The matching zero point clamping system within the machine tool is actuated pneumatically via the integrated interface on the gripper. The compatible vise size for the pneumatic gripper is Makro•Grip® 125. The maximum workpiece weight for this combination of gripper and vise is 25 kg, provided the standard Fanuc robot type M-710iC/50 is used. A larger robot variant is also available as an option, which increases the maximum workpiece weight to 45 kg for RoboTrex 96.

RoboTrex Automation System

By using RoboTrex, machining hours and thus productivity can be increased. RoboTrex covers every need from single part to large-scale production. It is flexible, easy to use and offers great value for money. This makes it appealing for SME’s and for those just starting out.

- Easiest operation The intuitive operation and the pre-adjusted robot do not require any special knowledge. Training is kept to a minimum.

- Fastest set-up time Thanks to offline preparation of the trolleys, the system is set up within a few moments without any machine downtime.

- Highest flexibility Both the offline trolley preparation and the diversity of machinable parts guarantee maximum flexibility.

Learn all about the benefits and functionality of the RoboTrex automation system.

Discover now