Key data at a glance

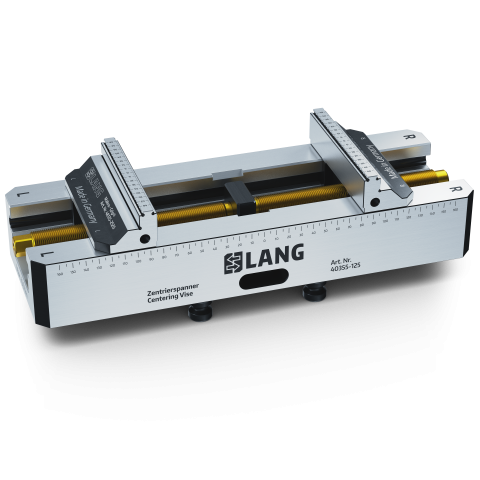

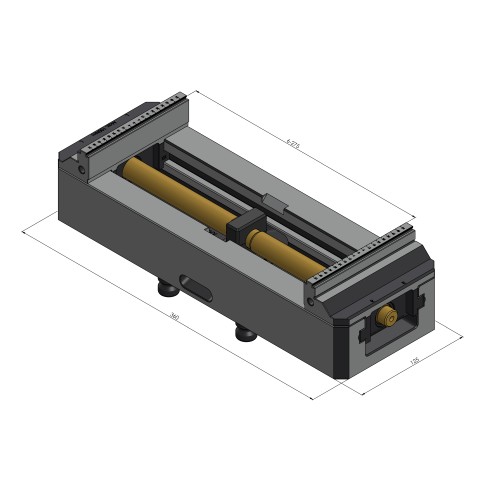

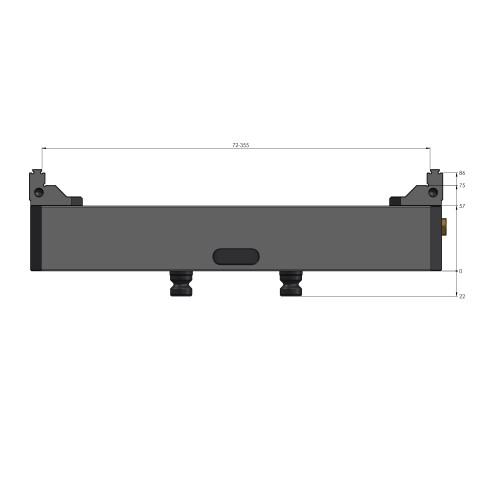

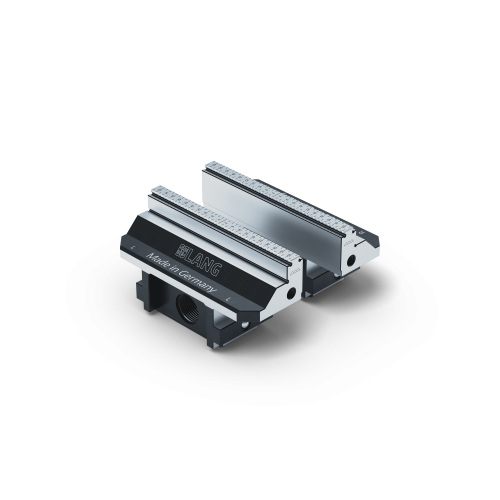

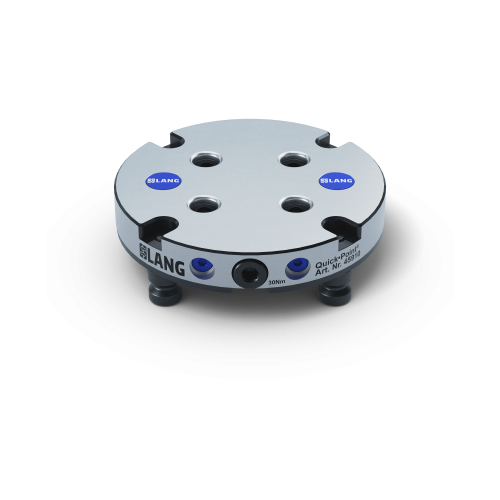

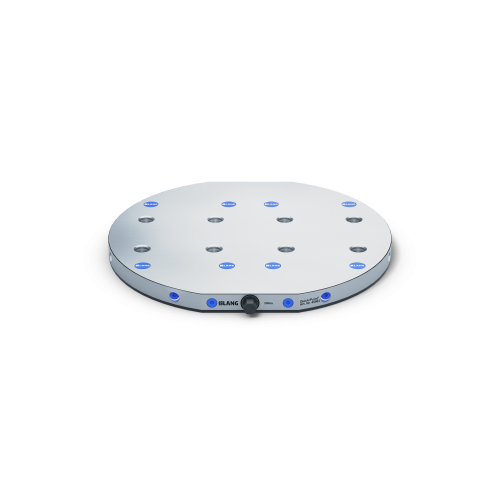

With a clamping range of 355 mm, this 5-Axis Vise is the largest among the Makro•Grip® vises. Its base body has a length of 360 mm, the jaw width is 125 mm. Due to its sturdiness and holding forces, the 5-Axis Vise is able to clamp workpieces that significantly exceed its volume. The form fit between the clamping jaws and the workpiece ensures maximum safety in the clamping process. Even with high tensile material, the required clamping pressure is low. This prevents wear on the clamping device and material deformation during machining.

More features:

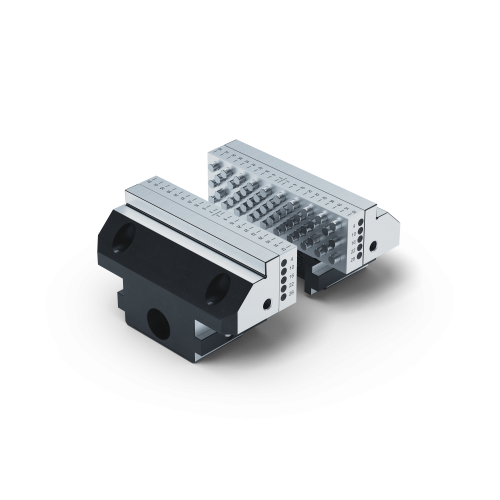

Single components features:

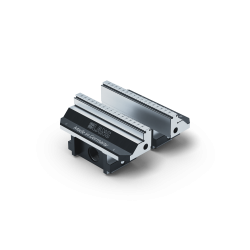

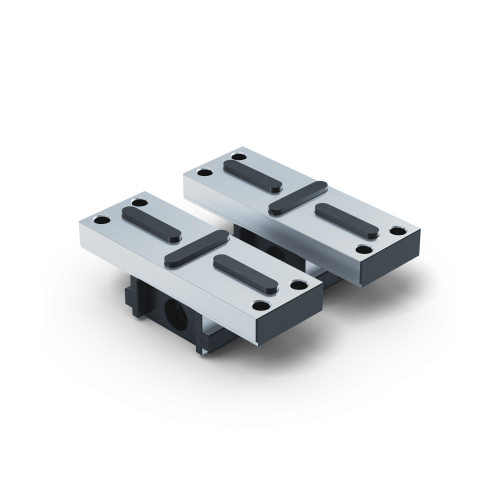

Spare Jaws

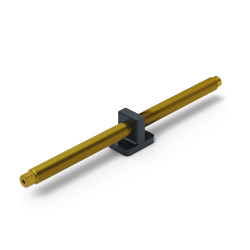

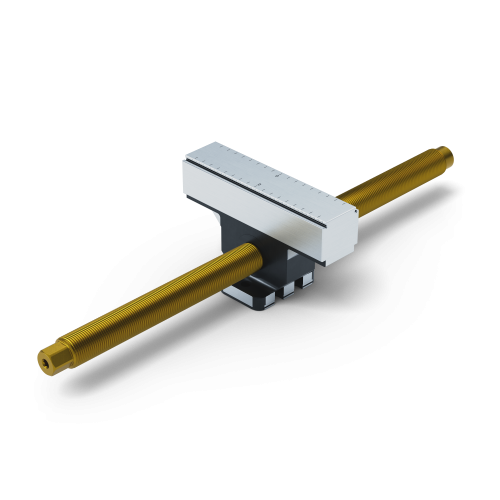

Spindle + Center Piece

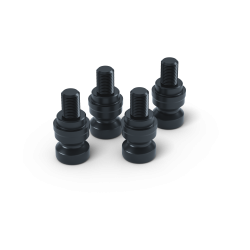

Clamping Studs

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover nowApplication pictures

Application videos

Services

We will be happy to advise you individually and adapt your products for the best possible application.

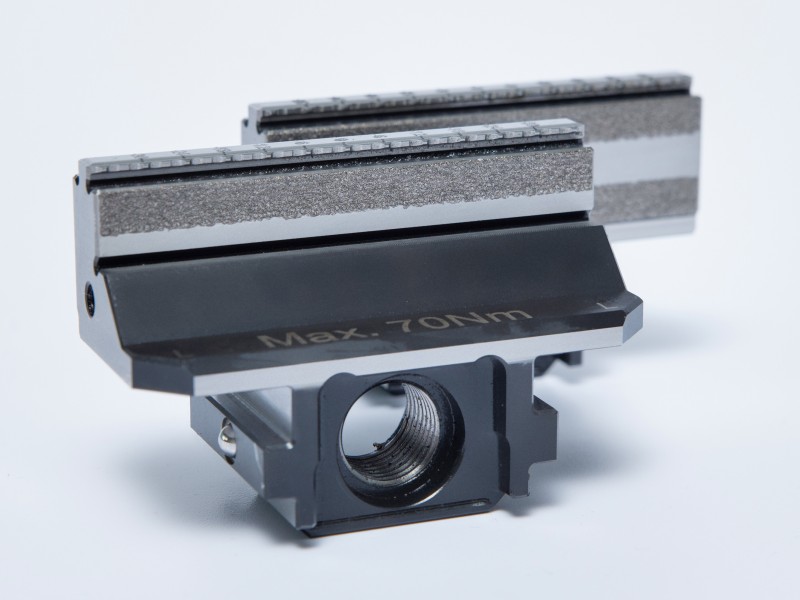

Tungsten-Carbide-Coating

A special Tungsten-Carbide Coating can be applied on the plain clamping surfaces of the Mak-ro•Grip® jaws in order to double the friction force when clamping non-stamped parts, without leaving any traces on the workpiece.

Modified Clamping depth

Sometimes raw material has a certain radius, which makes it hard to clamp it on the 3 mm step of the Makro•Grip® jaws. This can be solved by lowering the clamping step so that the workpie-ce is held above the radius. On the one hand, this provides a resting surface for the workpice, on the other hand it ensures safe clamping.