Key data at a glance

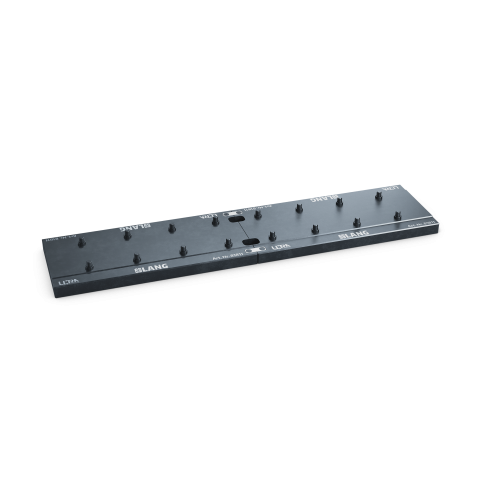

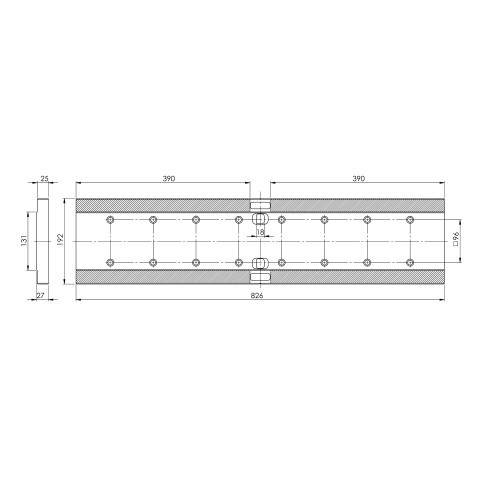

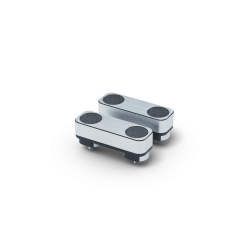

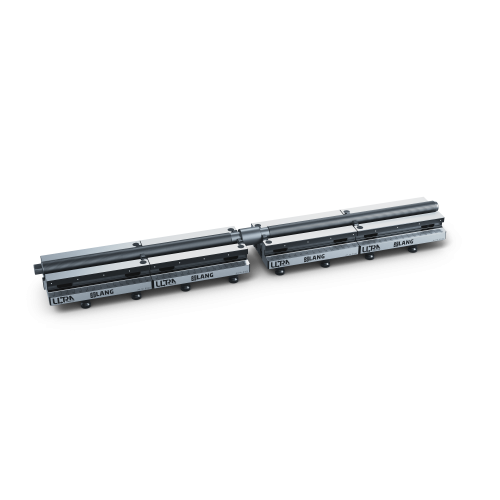

If it is not absolutely necessary to remove the Makro•Grip® Ultra clamping system from the machine table and thus use a zero point clamping system, Makro•Grip® Ultra can also be used without it. For this purpose, base plates made of non-hardened steel are available, which are fastened to the Makro•Grip® Ultra base sets from below using M 10 socket head screws and mounted firmly on the machine table. By fixing them in the slots of the machine table, the base plates can be flexibly moved in the x-direction, allowing the distance to an adjacent clamping unit to be reduced or increased.

More features:

Makro•Grip® Ultra

Makro•Grip® Ultra offers countless clamping possibilities and is perfectly fitted for machining applications of flat or large parts and also mould making. Thanks to its expandability and different jaw types, the modular clamping system practically covers any imaginable machining application.

- Modularity Changeover of clamping configuration within seconds through expansion of clamping ranges and exchange of clamping jaws

- Application diversity Equally applicable for single part or multiple clamping, cubic, round our asymmetric workpieces

- Centric clamping of large components Possibility of clamping workpieces of 800 mm or even larger

Learn all about the benefits and functionality of Makro•Grip® Ultra.

Discover nowDownloads

Services

We will be happy to advise you individually and adapt your products for the best possible application.

Set mounting bores according to customer's request

All of our Quick•Point® plates with prefabricated mounting bores are also available without such. The case-hardened zero-point plates (57 HRC, 0.7 mm deep) can be modified to fit almost any machine-tool table.