Key data at a glance

One right and one left threaded cap are required per clamping unit. By removing the threaded cap with a magnetic handle, the position of the clamping jaw can be changed in an instant without operating the spindle by sliding it on the base body. The threaded cap is secured by two heavy-duty hexagonal screws, which can be opened and closed with a half turn.

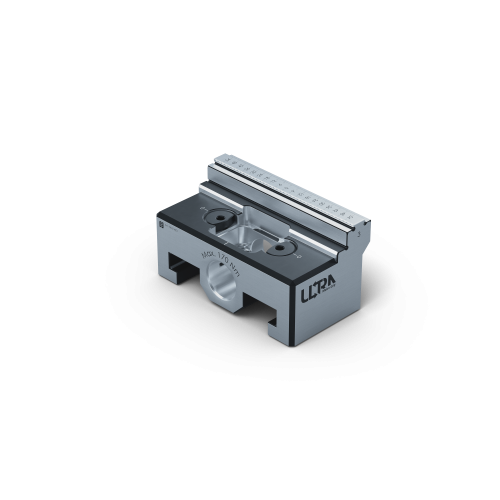

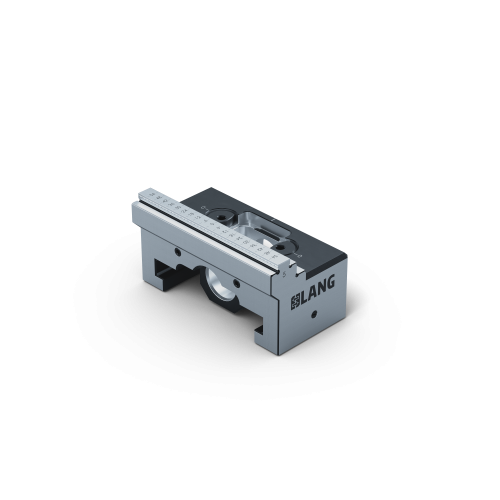

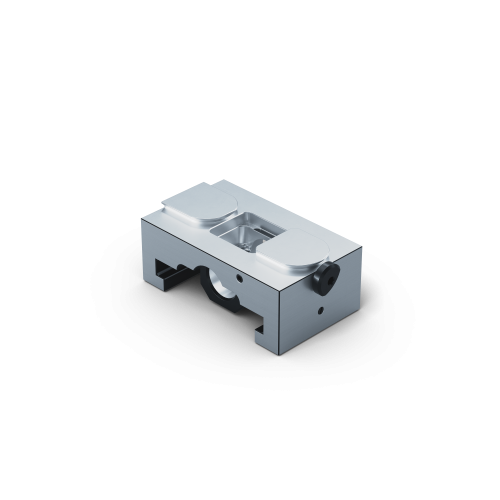

Makro•Grip® Ultra

Makro•Grip® Ultra offers countless clamping possibilities and is perfectly fitted for machining applications of flat or large parts and also mould making. Thanks to its expandability and different jaw types, the modular clamping system practically covers any imaginable machining application.

- Modularity Changeover of clamping configuration within seconds through expansion of clamping ranges and exchange of clamping jaws

- Application diversity Equally applicable for single part or multiple clamping, cubic, round our asymmetric workpieces

- Centric clamping of large components Possibility of clamping workpieces of 800 mm or even larger

Learn all about the benefits and functionality of Makro•Grip® Ultra.

Discover now