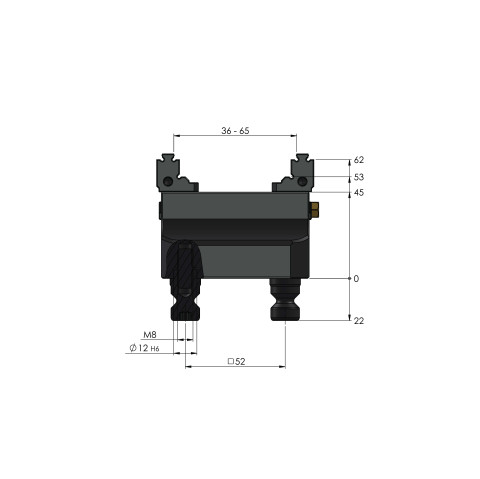

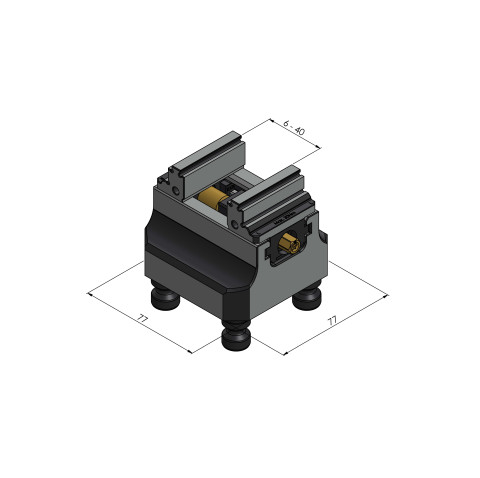

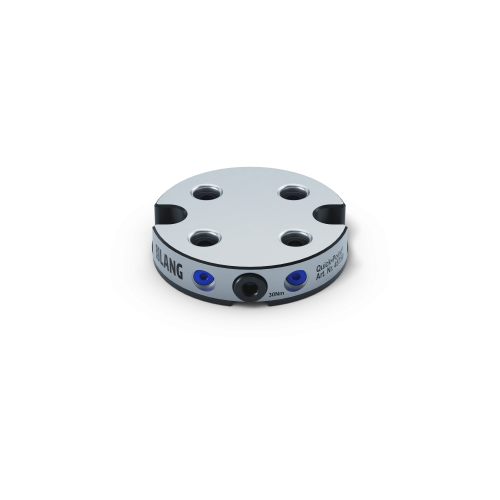

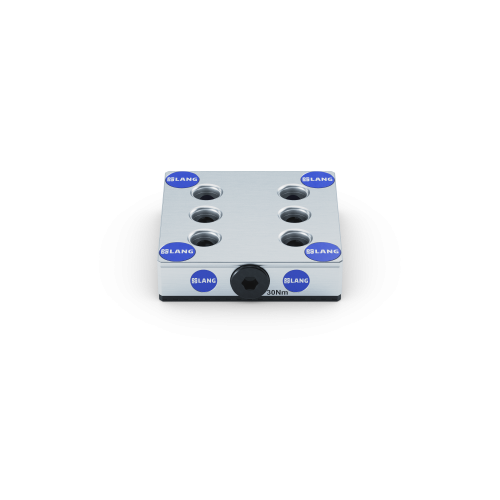

Makro•Grip® 46, 5-Axis Vise

Jaw width 46 mm, Clamping range 0 - 65 mm

Item No. 48065-46

This vise version is also available with Makro•Grip® FS clamping jaws (item no. 48065-46 FS).

Learn more

This vise version is also available with Makro•Grip® FS clamping jaws (item no. 48065-46 FS).

Learn moreKey data at a glance

The new Makro•Grip® 46 is the successor version of the popular, small 5-axis vise from LANG Technik (item no. 47065). With its compact base body, it is ideally suited for workpiece clamping of small components, for example from medical technology. The 5-Axis Vise proves to be extremely practical due to its small footprint of just 77 x 77 mm. Even with the smallest zero point plates, this vise does not protrude, which makes it particularly predestined for multiple part clamping.

More features:

Single components features:

Clamping Studs

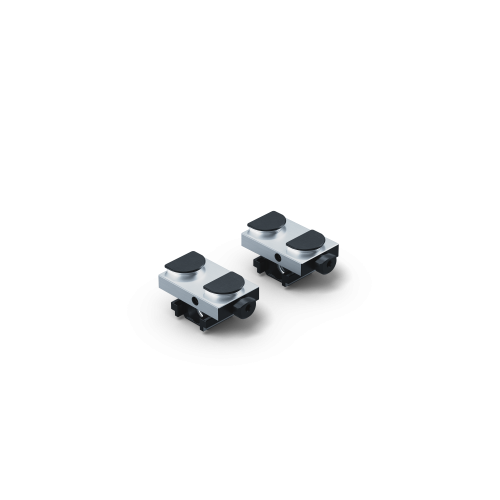

Spare Jaws

Spindle + Center Piece

Makro•Grip® Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Its compact design and high holding forces make the Makro•Grip® 5-Axis Vise the ideal clamping device for machining raw parts.

- Holding force Thanks to the form-fit clamping principle, highest holding forces can be achieved with Makro•Grip®, even at low clamping pressure.

- Process reliability Clamping with Makro•Grip® provides maximum process reliability and is easy on the workpiece to be processes at the same time.

- Accessibility The compact Makro•Grip® self-centering vises guarantee ideal accessibility in the 5-axis machining of raw parts.

Learn all about the benefits and functionality of ourMakro•Grip® Raw Part Clamping and Stamping Technology.

Discover nowServices

We will be happy to advise you individually and adapt your products for the best possible application.

Modified Clamping depth

Sometimes raw material has a certain radius, which makes it hard to clamp it on the 3 mm step of the Makro•Grip® jaws. This can be solved by lowering the clamping step so that the workpie-ce is held above the radius. On the one hand, this provides a resting surface for the workpice, on the other hand it ensures safe clamping.