Key data at a glance

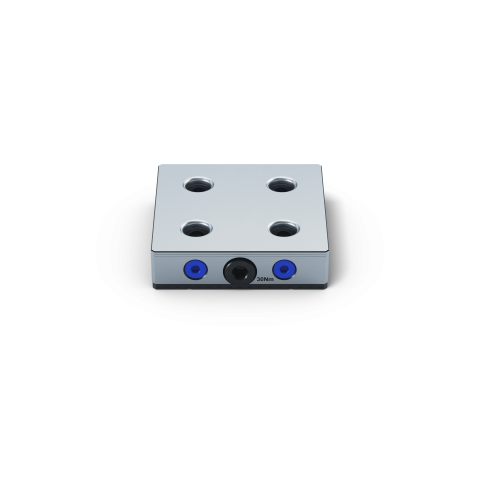

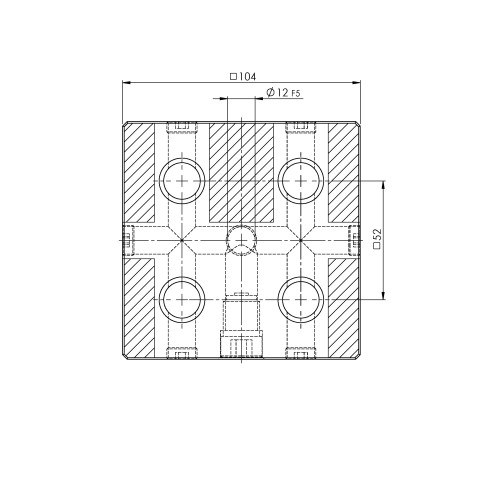

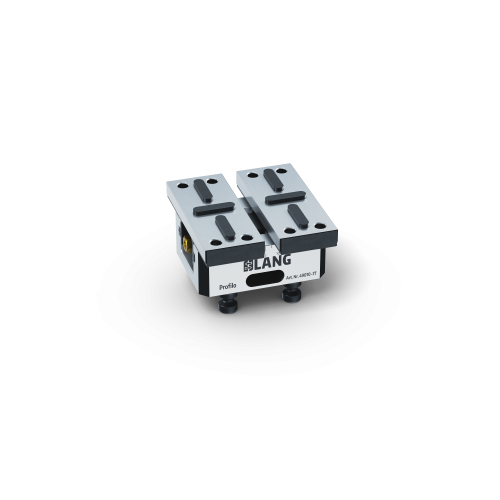

The smallest of the Quick•Point® plates with a grid size of 52 mm is often mounted in rows on trunnions or clamping towers and is used for the multiple clamping of smaller components. It is also used on pallets or angular clamps. It comes without predefined mounting holes, which allows for their individual creation. In its corners, it provides space for mounting holes up to a countersunk diameter of 17.5 mm.

More features:

Benefits Quick•Point® Single Plates

- Variety of versions Solutions for all types of machines and rotary tables available

- Simple Operation Easy handling thanks to the simple, mechanical functional principle

- Modifiability High degree of customisability

Quick•Point® Zero-Point Clamping System

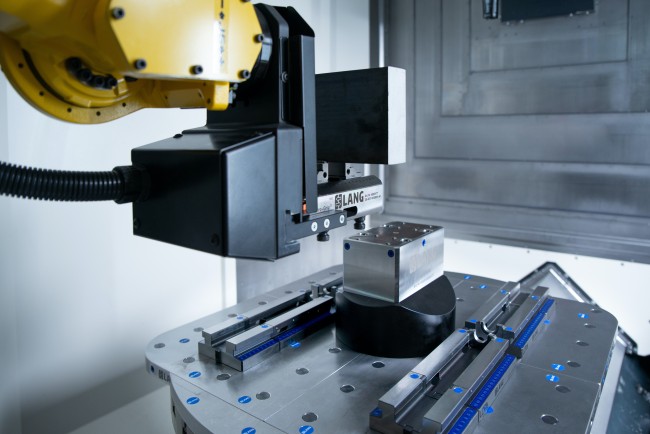

The Quick•Point® Zero-Point Clamping System is characterized by a particularly wide range of variations and provides a solution for any machine tool. Whether round, rectangular or square in shape, for single or multiple clamping, it can be universally used in vertical and horizontal machining centers, on 3- and 5-axis tables and 4th axis rotary or trunnion systems.

- Flexibility Thanks to the wide range of variations Quick•Point® can be retrofitted to any machine tool.

- Easy operation The simple and robust mechanical principle and the small number of components ensure maximum durability with little maintenance.

- Modularity Whether changing the system size or using additional zero-point components, Quick•Point® can be supplemented and expanded as required.

Learn all about the benefits and functionality of our Quick•Point® zero point clamping system.

Discover nowApplication pictures

Services

We will be happy to advise you individually and adapt your products for the best possible application.

Set mounting bores according to customer's request

All of our Quick•Point® plates with prefabricated mounting bores are also available without such. The case-hardened zero-point plates (57 HRC, 0.7 mm deep) can be modified to fit almost any machine-tool table.