Key data at a glance

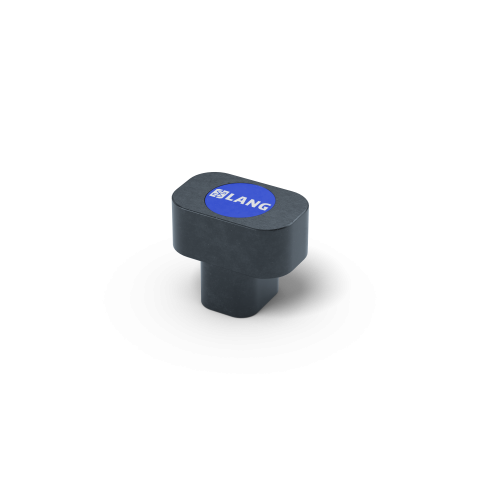

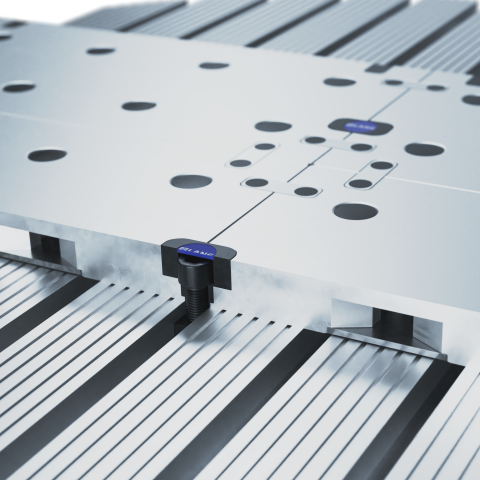

Alignment claws are used for the simultaneous fastening and alignment of Quick•Point® zero point plates lined up next to each other. They can be used when two zero point plates are positioned on the machine table in such a way that they are directly next to each other above a table groove and fastening holes in this area appear to make sense. For this purpose, a corresponding hole must be made across the plate, into which the alignment claw is inserted and fastened with a cylinder head screw countersunk in it and a T-slot nut.

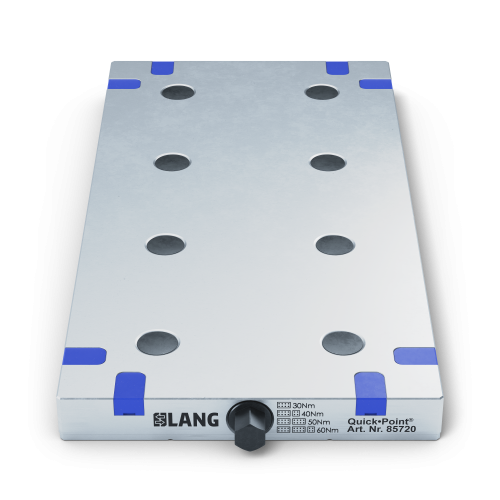

Quick•Point® Zero-Point Clamping System

The Quick•Point® Zero-Point Clamping System is characterized by a particularly wide range of variations and provides a solution for any machine tool. Whether round, rectangular or square in shape, for single or multiple clamping, it can be universally used in vertical and horizontal machining centers, on 3- and 5-axis tables and 4th axis rotary or trunnion systems.

- Flexibility Thanks to the wide range of variations Quick•Point® can be retrofitted to any machine tool.

- Easy operation The simple and robust mechanical principle and the small number of components ensure maximum durability with little maintenance.

- Modularity Whether changing the system size or using additional zero-point components, Quick•Point® can be supplemented and expanded as required.

Learn all about the benefits and functionality of our Quick•Point® zero point clamping system.

Discover now