Equipping your machine: make it easy for yourself

Topic video

This video is hosted on YouTube. To watch the video please accept the media cookies in the privacy settings.

Welcome to the parts universe: there is nothing that does not exist

Once the job or a machining sequence is finished, changeovers takes place and everything starts again from the beginning. The most important task of a clamping system is to lock the part in place in order to be able to handle the machining forces in the turning or milling process.

Important: The clamping system or clamping device must match the component geometry and the machine process. Typical shapes for components in an industrial environment are cuboids, cubes, prisms, pyramids, cones, spheres, cylinders and others. If workpieces are manufactured individually or in series, part quality is ensured by using a zero point clamping system, which ensures the necessary accuracy and repeatability of the machining processes by means of a predefined reference point. Choosing the right clamping device here has a significant impact on the efficiency of the machining process on a machine, as the machine can be set up more quickly.

Why zero-point clamping systems are not always efficient

However, potential is still being wasted here too, as the zero point clamping system is often only placed in the center of the machine table for simple single clamping. The remaining space often remains unused. As safe as zero point clamping systems are, efficiency can certainly diminish at this point.

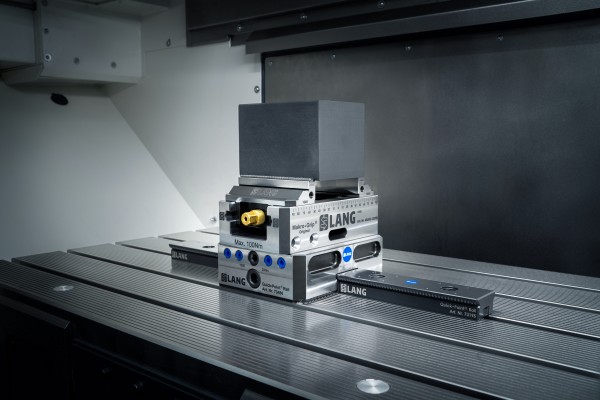

The Quick•Point® Rail quick clamping system puts an end to this and can be used more efficiently than many zero point clamping systems. It can be installed in any CNC milling machine and does not require a base plate.

Here today, there tomorrow: flexible positioning of the zero point clamping system

But how can the range of tasks be expanded? Quite simply: by moving the clamping device variably using the Quick•Point® Rail clamping bars. The length of these depends on the component length - anything is possible with combinations. Especially when two clamping devices are in use, the distances between the two clamping devices can be flexibly adjusted using the Quick•Point® Rail clamping system. This is made possible by a 4 mm grid that can be moved back and forth as required.

Risers are also frequently used in the zero point clamping system to increase the distance between the machine table and the workpiece. Once inserted in the zero point clamping system, these are firmly locked in place on the automation pallet or machine table. With the Quick•Point® Rail quick clamping system, a zero point riser can now be moved for the first time and still leave the desired space. Quick•Point® Rail takes just a few minutes to install and turns a reliable zero point clamping system into a movable zero point clamping system with a wide range of options.

Let's groove: Quick•Point® Rail takes what's there

The quick-clamping system makes use of the existing conditions in the machine tool. Quick•Point® Rail can be fastened in the grooves of the machine table. This is done with the aid of sliding blocks. The clamping bars are fixed above this using cylinder head screws. If you are working with automation pallets, simply screw the clamping bar of the Quick•Point® Rail clamping system directly onto the automation pallet using the existing threaded holes. The clamping rails are available in different versions so that it can always be guaranteed that the available width of the base is ideally utilized. The Quick•Point® Rail starts with performance improvements where every machining task begins: with the increase in clamping efficiency.

Questions and answers

How is the quick-clamping system attached?

The quick clamping system is mounted directly onto the machine table, an automation pallet or a swivel bridge. There is no need for base plates. On the one hand, this ensures a faster installation process and, on the other hand, it saves enormous costs, especially in large quantities, e.g. when used on pallet automation systems.

Does a machine table have to be prepared for the use of Quick•Point® Rail?

The quick-clamping system can be attached directly to the grooved table of a milling machine without any preparation. No additional time or costs are required, for example for adapting the table. This means that the quick-clamping system can also be removed from the machine table without leaving any residue.

Who is Quick•Point® Rail intended for?

The quick-clamping system is suitable for all companies in the machining industry that are looking for a cost-effective and quick way to attach vises and zero-point elements to machine tables and automation pallets.